Green Recycling, an industrial and commercial waste company based in Essex, U.K., has purchased a Max-AI AQC (Autonomous Quality Control) unit to increase recovery of recyclables without adding additional manual labor at the company’s commercial and commingled dry recyclables material recovery facility (MRF) in the Essex town of Maldon. Green Recycling is the first company in the U.K. to invest in this technology, which had been installed in three U.S. MRFs prior to this installation. Green Recycling’s Max-AI AQC will be operational in the first quarter of 2018, according to a press release issued by BHS and Green Recycling.

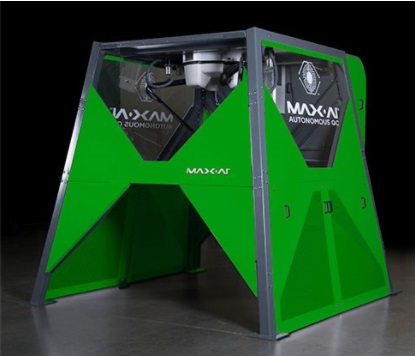

Eugene, Oregon-based Bulk Handling Systems (BHS), which launched the technology in 2017, says the Max-AI AQC incorporates an AI-powered vision system to identify recyclables and make decisions, along with a robotic sorter that picks items and places them into chutes. The artificial neural network technology mirrors the neural framework of the human brain to identify recyclables in a manner similar to that of a person. When the recyclables have been identified by the vision system, a robotic sorter then does the picking, the company says.

At Green Recycling’s facility, equipment is used to open bags and collect plastic film and old corrugated containers (OCC). Screen and air separation technologies then segregate material. The Max-AI AQC follows this equipment, working on the recovery line to capture card, news and pams, high-density polyethylene (HDPE) natural, polyethylene terephthalate (PET) bottles and wood.

The Max-AI AQC intelligent vision system is trained using a process called deep learning and can immediately identify various recyclables, according to BHS. Max-AI AQC also is capable of making various decisions, including prioritizing the picking order based on size, value and location, directing the robotic sorter to pick and place the recovered end products into chutes.

BHS says the Max-AI AQC can make approximately 65 picks per minute, a productivity rate that would require Green Recycling to source and employ staff in two manual sorting positions, positions that are difficult to fill because of the nature of the job.

When the new equipment is in place, Green Recycling will be able to run this section of the recovery line with no human sorting at all, BHS says.

Rob Smith, managing director at Green Recycling, says, “We believe that this technology will revolutionize MRF operations, and we’re excited to be the first to introduce it here in the U.K. Our aim is to deliver a flexible and efficient recycling process to our customers, and we’re always on the lookout for the latest technology to further automate and improve our process. We believe we have found it with Max-AI AQC. Not only is the technology capable of sorting up to six different end fractions in one location, but it is also adjustable should the material or markets change and will deliver significant operational improvements. We can’t wait to put Max to work!”

Jamie Smith, general manager at Green Recycling, says, “With the addition of Max-AI to our team, not only will we significantly improve our recycling efficiency but more importantly we will shift job specification to a technology-based outlook. While the perception would be to replace human sorting, here at Green Recycling it will actually be creating opportunity with a new technology based position for a brand new member of staff.”

BHS appointed Steve Almond to the position of sales consultant for the U.K. and Ireland earlier this year.

“I wanted to represent the Max-AI product line because I believe that this technology is a game changer for my customers,” Almond says. “MRF operators consistently face challenges when humans have direct contact with the waste stream: staffing problems, high labor costs, health and safety risks and management and performance-related loss. I’m looking forward to delivering this unit and helping a valued customer overcome these challenges and increase operational performance.”

He adds, “Green Recycling has opted to embrace innovation and as the first in the U.K. to introduce this technology; I’m confident that the investment will be as successful for the company as it is noteworthy.”

The Max-AI AQC can be viewed in operation at https://youtu.be/2gjUpDnJrZA.