Petrochemicals – Bioplastic – BGPET 08-05-2023 - Arhive

Petrochemicals – Bioplastic – BGPET

Petrochemicals – rPET – BGPET

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-BASF, Krones, Südpack, and Tomra have partnered to tackle the issue of unrecyclable multi-layer film packaging, which is still widely used in the food industry.

The packaging’s different layers are often made from different materials, making recycling difficult.

The EU’s upcoming Packaging and Packaging Waste Regulation (PPWR) aims to make all packaging on the EU market recyclable in an economically viable way by 2030.

To comply with this regulation, the partners have demonstrated that PET/PE multi-layer packaging can be separated into its individual components and reused as raw materials. During the first industrial trial, conducted at a Krones pilot plant, the partners were able to completely separate as much as 69 percent of the PET/PE components and partially separate another twelve percent. Petrochemicals – Bioplastic – BGPET

This was achieved using existing recycling infrastructure, and the project is ongoing, with the partners seeking to optimize the recycling process and improve the quality of recycled materials.

The aim is to re-use the PET for food packaging and the PE fraction for non-food packaging.

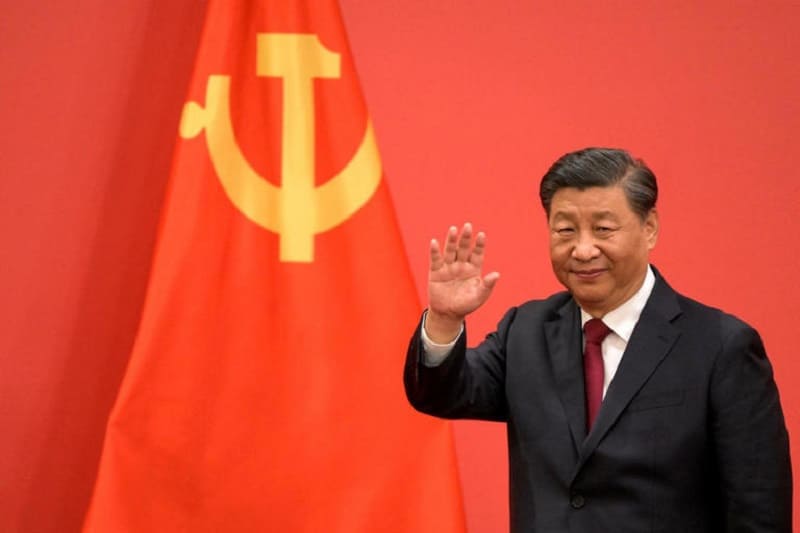

– An expert in international economics and Asia,Mr.Alberto Forchielli, believes that China is the primary rival to Western energy transition policies.

He states that China has created a dependency relationship in many sectors critical to the energy transition, including wind turbines, electric vehicle batteries, solar panels, and inverters.

Forchielli notes that China has become the world’s leading exporter of electric cars due to its dominance in electric vehicle technology.

He attributes China’s success to its ability to plan development from above and subsidize critical sectors to expand demand for businesses.

China’s manufacturing advantage, combined with economies of scale, allows it to maintain cost advantages over the West.

Forchielli also highlights the laxity of the West in addressing this dependence, and he cites the example of the joint venture between Ford and Chinese Catl, which underscores China’s dominance in new technologies. Petrochemicals – Bioplastic – BGPET

He relates the issue of critical mineral value chains to this and states that China has built secure supply chains for critical minerals, creating a structural dependence on the West. Forchielli suggests that the West should use industrial and market planning, incentives, and duties to defend critical industries to break dependence on China in the energy transition.

-The battery that recharges in three minutes arrives in June

It was created by the collaboration of Nyobolt and Callum and promises to cut charging times from 3 hours to 3 minutes

Soon the long waits to recharge the electric car will be just a memory. Or at least this is what good news from the United Kingdom promises, where Nyobolt says it is ready to present a revolutionary battery.

The innovative composition of the accumulators promises to reduce recharging times from 3 hours to 3 minutes, thus facilitating everyday life, both for cars and for all other rechargeable devices. Petrochemicals – Bioplastic – BGPET

Will this be the battery of the future?

The battery is the result of collaboration with Callum, a company specializing in the fields of design and engineering, and will be presented next June. Nyobolt does not yet reveal the composition of the accumulator in detail, even if it speaks of “unpublished” materials, a new, more compact design of the cells and an “efficient control software”.

So Sai Shivareddy, the CEO of Nyobolt:

“We have managed to fully unlock the potential of batteries to give birth to a new generation of technologies. The growth in the sale of electric cars all over the world makes it clear that the industry needs solutions of this type, capable of reducing recharging times”.

Matter of batteries and columns

The British company is not the only one interested in making super-fast batteries. For example, StoreDot is testing the XFC, batteries that promise to recharge 160 km in 5 minutes, with 15 car manufacturers already interested.

Then there are the CATL sodium ion batteries, compatible with an 800-volt architecture and capable of charging in 5 minutes. Petrochemicals – Bioplastic – BGPET

In addition to accumulators, there are those who are moving forward with ultrafast columns, with structures up to 480 kW that have already made their debut in China. Without forgetting the Tesla Megachargers, the immense columns for recharging the Semi truck with up to 1.5 MW of power.

-Top 5 Bioplastic Companies (May 2023)

The Plastic Age

Plastic is an omnipresent material in modern life. We use it for packaging food and drink, and in manufacturing like making pipes, clothing, or even cars and airplanes.

This is also a material made almost exclusively from fossil fuels. While it can somewhat be recycled, after enough cycles, it will ultimately end up “consumed”.

The worst is having it turned into trash in the environment, or into micro-plastic pollution, which happens to roughly 80% of total plastic usage. But even if incinerated, it will produce CO2, like any other fossil fuel combustion.

This is not a fatality however, plastic is essentially carbon chains assembled in specific ways. So there is no reason that organic materials could not provide the basic components for plastic manufacturing. Petrochemicals – Bioplastic – BGPET

Bioplastics

To answer the growing concern about plastic production, bioplastics have been developed. They are made from plant materials, often leftovers from other industries like paper mills or farming. The sector is expected to reach $25B by 2027, growing at 14.9% CAGR (other studies anticipate a 17% growth).

Still, bioplastics represent just 1% of the total market currently dominated by fossil fuel plastics, leaving a very large addressable market.

A subsection of this category is biodegradable plastics, which is more environmentally friendly. Most bioplastics are easier to degrade than usual plastics. On that topic, research is also done to find microbes able to digest “normal” plastic, in order to solve the micro-plastic pollution issue. Petrochemicals – Bioplastic – BGPET

Overall, people are ready to pay more for eco-friendly products, with a growing trend, especially among younger people in the last few years.

Stock Selection Strategy

Despite the “bio” part, the bioplastic creation process is very much a chemical engineering issue. So as you will see, it is not surprising that most of the industry leaders are also the leaders in the chemical industry or spin-offs from it.

Nevertheless, investors looking into bioplastics might not want to directly invest in giants like BASF, as the bioplastic part is almost irrelevant to the company’s overall business. For example, BASF will much more likely be dependent on the price of natural gas in Germany.

The following list is focused on smaller publicly traded companies, with a strong focus on bioplastics and eco-friendly solutions. Petrochemicals – Bioplastic – BGPET

-Neste moves forward in its renewable hydrogen project in Porvoo, Finland

In accordance with its ambition to reach carbon neutral production by 2035, Neste is working on a 120 MW electrolyzer project to produce renewable (i.e. green) hydrogen at its Porvoo refinery in Finland, said Hydrocarbonprocessing.

The company has now decided to proceed to the basic engineering phase with the project. The investment decision readiness is expected to be reached in early 2024. If an investment decision is made, green hydrogen production could start in 2026.

“Our project is one of the largest development projects to produce green hydrogen in the European refineries and it supports our goal to transform the Porvoo refinery to the most sustainable refinery in Europe by 2030.

The green hydrogen would be primarily used in our Porvoo refinery’s processes, where it would replace hydrogen produced from fossil feedstocks,” says Markku Korvenranta, Executive Vice President in Neste’s Oil Products. Petrochemicals – Bioplastic – BGPET

Production of green hydrogen also generates renewable heat. In connection with the 120 MW green hydrogen project, Neste has started a preliminary study with Porvoon Energia on the utilization of renewable heat in district heating. Porvoon Energia is a regional Finnish energy company focusing on heat and electricity production and distribution as well as development of the electricity network.

Hydrogen projects at Neste’s Porvoo refinery contribute considerably to the EU green hydrogen value chain. In July 2022, Neste became the first Finnish company to receive IPCEI (Important Project of Common European Interest) status from the European Commission for its hydrogen projects. In December 2022, Business Finland awarded Neste EUR27.7 MM of public funding for its renewable hydrogen projects at the Porvoo refinery.

-TPE Made with 50% PCR Derived from End-of-Life Tires

Prism Worldwide has commercialized its first TPE with this type of recycled content based on its patented technology. Petrochemicals – Bioplastic – BGPET

A thermoplastic elastomer (TPE) made of 50% post-consumer recycle content derived from end-of-use tires while maintaining the look, feel and processing of a typical petrochemically derived TPE has been introduced by Prism Worldwide of Kirkland, Wash. Company sources confirm that this is the first such TPE launched and that its patented Prism technology is compatible with both styrenic and olefinic based resins.

This process uses tire rubber as the primary feedstock in the production of polymer intermediates called PTR. These intermediate polymers are then compounded into injection moldable TPE pellets at the company’s facility in the Rochester, N.Y. area. (In November 2022, Prism acquired CRC Polymer Systems (CRC), a custom compounding company supplying compounds, resins, and colors to the plastics industry._

The first compound in a series, Ancora C-1000, is suitable for use in a broad range of applications, such as automotive all-weather mats, weather stripping, and footwear. Available in black, the compound has a Shore A of 80 and is 99% domestically sourced meeting IIJA Buy America requirements. Petrochemicals – Bioplastic – BGPET

Compared to virgin synthetic rubber compounds, Prism’s base polymer has approximately 86% lower carbon footprint. “There is growing demand for recycled content throughout the industry, and high recycle content TPEs are not widely available in the marketplace. This product fills a unique market demand for both sustainability and performance. The technology we use can be applied over a broad range of applications and we look forward to working with the industry to grow this into a family of TPE compound products,” said Prism’s chief commercial officer Mark Kinkelaar.