Petrochemical PETChip Recycling Textile 03-12-2020 - Arhive

Petrochemical PETChip Recycling Textile

Crude Oil Prices Trend

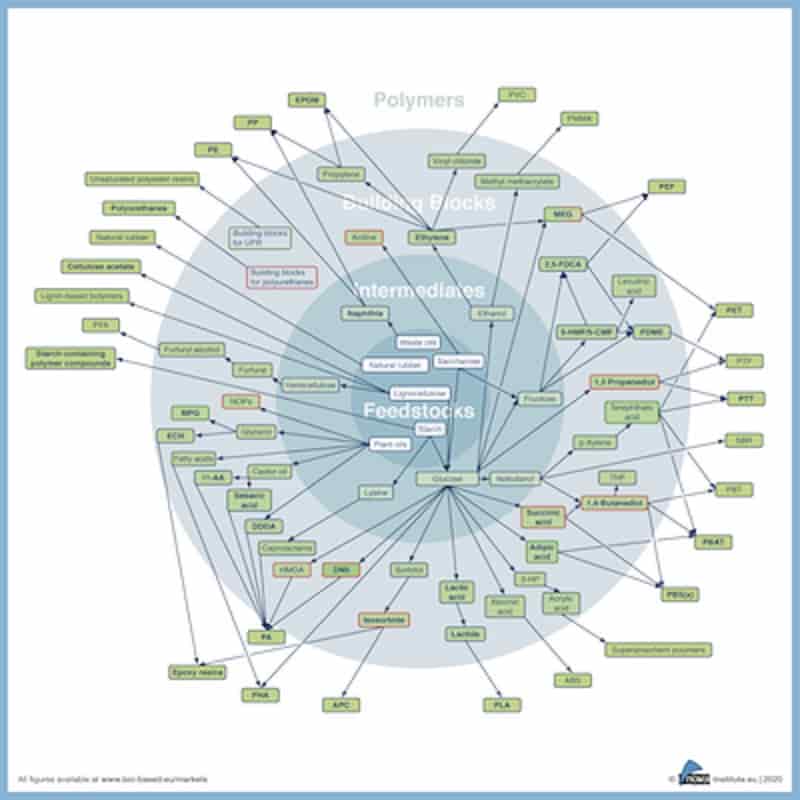

– “Renewable Polymers: Production and Trends 2020-2025”

Renewable Polymers and Building Blocks: Technologies, Global Capacities, Production and Trends 2020-2025

Bio-based and CO2-based Solutions

The only way for chemicals and plastics to become sustainable, climate-friendly and part of the circular economy is the complete substitution of fossil carbon with renewable carbon from alternative sources: biomass, CO2 and recycling. Sold out PLA in 2019 has led to the installation of increased capacities in 2020, PE and PP made from bio-based naphtha are breaking ground and future expansion for bio-based polyamides will come into place, growth for bio-based polymers is expected to over 6 % until 2025. Additionally, the use of CO2 as chemical feedstock for polymers has been intensively diversified. Besides the long-established use of CO2 for the synthesis of polycarbonates, also polyurethanes can already be based on it. Optimised technology approaches in fermentation, electrochemistry and catalysts for conversion are emerging and broaden the CO2-based polymer portfolio.

-Resilux chosen by Dansk Retursystem to accomplish complete closed loop recycling

Resilux recently signed a long-term contract with Dansk Retursystem to recycle PET and so deliver full circularity from used food grade bottles to new bottles in the Danish market. In addition, rigorous traceability and transparency gives fillers in Denmark and other countries confidence about the origin of the recycled PET that Resilux can return to them. The Danish deposit and return system which is operated by Dansk Retursystem is a leading example of how full, closed loop circularity in PET can be achieved. Petrochemical PETChip Recycling Textile

Closed loop PET recycling in Denmark

The non-profit company Dansk Retursystem ensures that disposable beverage packaging made of plastic, aluminium and glass is seen as a valuable resource and that it is recycled in Denmark. For PET bottles, reverse vending machines are used to give consumers an additional incentive to bring their bottles back. Used ones are then taken to centralised sorting units where they are baled-up and made available to participating recyclers such as Resilux to purchase – on the understanding that they are obliged to put them back into new bottles (through the supply of preforms). Resilux will try to put them back into the Danish market which will make a perfect closed loop.

-PrintCYC: Successful recycling of printed plastic films and processing of recyclate

Cost-effective solutions for a circular economy based on postindustrial waste from printed plastic films

- High quality recyclates comparable to virgin material

- Recyclate reuse up to 100% in divers packaging applications

- Significant improvement of recycling by PU based ink system

PrintCYC is a value chain initiative for the recyling of printed films. Current members are the machine suppliers Brückner Maschinenbau, Kiefel and PackSys Global, the CPP film specialist Profol, the ink manufacturer hubergroup, the converter Constantia Flexibles as well as the recycling technology specialist Erema.

The initiative is coordinated by Annett Kaeding-Koppers as independent packaging and sustainability consultant. Petrochemical PETChip Recycling Textile

The project group has achieved remarkable results regarding the recycling of printed plastic films and processing of recyclate. The need for circular economy solutions for plastic packaging requires the packaging industry to take an active role in ensuring circularity starting from design, following the entire life cycle.

-Automotive – impact on chemicals

The automotive industry has an important relationship with the chemicals sector while remaining an instrumental force on the global economy as an employment-intensive sector. Petrochemical PETChip Recycling Textile

In a fast-changing world, automotive manufacturing is susceptible to unique challenges. While vehicle manufacturers are impacted by material prices, trends impacting the market ripple upstream.

September’s light vehicles sales were up 0.5% year on year and largely in line with the previous two months. This is well ahead of numbers seen in the first half of the year and represents decent demand. However, the results are very uneven across the globe. Countries which have been most successful in containing the virus (China and South Korea) have enjoyed the sharpest rebound in sales. Renewed outbreaks at plants in the US and Europe have disrupted supply, and demand could weaken as unemployment rises and working from home increases over the winter.

-December contract price of benzene in Europe increased by EUR103 per ton

The contract price of benzene in Europe for deliveries in December this year was finally agreed at EUR521 per tonne, which is EUR103 per tonne higher than the November price, ICIS reported. Petrochemical PETChip Recycling Textile

The contract price was approved on terms of delivery CIF NWE (North West Europe).

The December material price has been confirmed by two sellers and three buyers, which is a sufficient minimum configuration to negotiate a contract price.

The December contract price for benzene was negotiated in dollar terms at USD621 per tonne and then converted to a price in euros at the agreed exchange rate of EUR1 = USD1.1922.

Thus, if we take the price of benzene in dollar terms, then the December contract price for the material increased by USD132 per tonne compared to November .

-PKN Orlen plans major expansion of petchems, renewables

PKN Orlen (Plock, Poland) will invest an average of 4.4 billion zloty (USD1.2 billion) per year between 2021 and 2030 on a major expansion of its integrated petrochemicals business and the creation of a plastics recycling division as part of an enhanced strategic focus on petchems and renewables over the next 10 years, according to Chemweek.

By 2030 it will have an annual petchems output of approximately 15 million metric tons, and be “an active player” in plastics recycling with 300,000-400,000 metric tons/year of installed capacity, PKN Orlen says.

The strategic expansion is forecast to increase its petchems EBITDA from Zl 2.3 billion in 2019 to approximately Zl 7.0 billion by 2030, according to the company. “We are set to become one of Europe’s largest integrated petrochemical producers and expand our recycling business,” it says. Petrochemical PETChip Recycling Textile

The capital expenditure (capex) plans, outlined in its latest strategy update, are being implemented to achieve targets including expanding the share of specialty products in its petchems portfolio from 16% in 2019 to 25% by 2030, and ramping up its production capacities for olefins and other base chemicals in order to supply feedstock for the development of the specialty and other advanced petchems products. The increased focus on petchems will specifically include expanding its position in products such as phenol and other aromatic derivatives, it says.

-Polimekh has launched a line for recycling film waste in the Moscow region

The Polimech company (Polimech, Moscow) has launched a line for the processing of highly contaminated film materials with a capacity of 500-600 kg / h in the Moscow region, the company said.

The line includes a washing and drying complex of the latest generation with automatic removal of dirt and a highly efficient press-pressing for drying film materials, as well as a fully automatic granulation line with a thermal compactor, a non-stop melt filter with self-cleaning, and automatic filling into big bags.

The complex is equipped with a belt conveyor with a metal detector, a crusher model SLU-750 and a screw conveyor S-SHT-550. Waste plastics are cleaned through a flotation washer with dirt removal and an intensive screw cleaning, as well as a S-MFK-404 flotation bath and a water treatment bath. The line has a CP-30 centrifuge to separate the label.

-Planet Recycling Joins Aquafil to Close Loop on Waste Carpet

Aquafil Group, based in Cartersville, GA, has announced that the Planet Recycling Inc. carpet collections network will join its journey to the circular economy in mid-December 2020. Phoenix-based Planet Recycling has been recycling residential and commercial carpet waste and carpet pad materials for more than 35 years.

Planet Recycling diverts more than 10,000 tons of post-consumer carpets and carpet pads from Phoenix Valley and San Diego County landfills each year. The company’s existing collection facilities will enhance the availability of used carpet material for the Aquafil carpet recycling facility in Phoenix.

It will also create a stable quantity of nylon waste for a regeneration plant in Solvenia, where carpet waste and other materials, such as fishing nets, are regenerated to make Econyl yarns and polymers.

-Weekly Resin Report: Traditional December Discounts May Not Materialize

Thanksgiving week was marked by mixed spot resin trading activity, with better-than-expected polyethylene (PE) demand more notable than the continued lack of polypropylene (PP), reports the PlasticsExchange in its Market Update. Export buyers raised their bids, which helped to clean up the lower side of the Houston pricing spectrum, but not enough to move the needle on benchmark prices, which held steady across the board. Completed volumes in November at the PlasticsExchange trading desk tallied among the lowest of 2020. Petrochemical PETChip Recycling Textile

Overall Prime resin availability remained low throughout the month. While PP buyers generally paid up to get materials in need, PE buyers were more reticent. They have been holding out for a significant price break that has yet to develop. PE contracts rolled flat in November, and producers will give their outstanding nickel hike a third shot in December. PP contracts will rise at least $0.02/lb along with PGP monomer, but will likely see another $0.03 to 0.04/lb stick, as producers have been rightfully pushing for margin expansion, writes the PlasticsExchange. Robust demand from Asia, which seems to be accelerating, could help keep the supply/demand dynamic very tight, as upstream inventories try to recover from storm-related production disruptions.

Kipas, a Monforts customer, is currently installing its third Monforts Montex stenter in Kahramanmaras. Petrochemical PETChip Recycling Textile

Kipas is also installing a third Monfortex compressive shrinkage system in a combined configuration dedicated to denim production at its Kahramanmaras site in Turkey. This follows the successful installation and commissioning of the second Montex and Monfortex lines at the Kahramanmaras plant in 2018, which Kipas vice chairman of the Board Ahmet Oksuz said had immediately exceeded expectations.

“We performed a very thorough technical investigation based on the latest Industry 4.0 analysis before the purchase, to determine what we needed, and the Monforts technology met all our requirements,” a Monforts press release quoted Oksuz from one of his interviews.

Petrochemical PETChip Recycling Textile