Anti-UV-PET – Chemical recycling 10-05-2023 - Arhive

Anti-UV-PET – Chemical recycling

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Canada is suggesting significant control over plastics that are facing consumers

On April 18, 2023, the Canadian government put forward proposed measures to support its objective of zero plastic waste. These proposed measures consist of three primary initiatives:

- All consumer-facing plastics would require labeling for recyclability and compostability.

- Various groups of plastic packaging would have mandatory minimum levels of recycled plastic.

- A national plastics registry would be created.

Environment and Climate Change Canada is asking for feedback on these proposed measures, with comments due by May 18, 2023. Anti-UV-PET – Chemical recycling

A. Proposed Labeling Regulations:

Under the current proposal, consumer-facing plastic packaging (whether primary, secondary, or e-commerce packaging) and single-use plastics (SUPs) would need to have a prescribed symbol that would indicate recyclability information. This includes both biobased plastics made from renewable resources and conventional plastics.

Reusable packaging that can be used multiple times in a reuse or refill system would not have to comply with the labeling requirements. Certain products (e.g., small items with a display surface of less than 15cm2) would be exempt from the mandatory recycling symbol requirement.

- Recyclability:

The proposal requires plastic packaging or a SUP to undergo a recyclability evaluation in each province or territory before it can be put on the market. The evaluation must consider all of the product’s components against three criteria: collection, sorting, and re-processing to decide if the product (or individual components) is classified as “recyclable,” “non-recyclable,” or “collected.” Anti-UV-PET – Chemical recycling

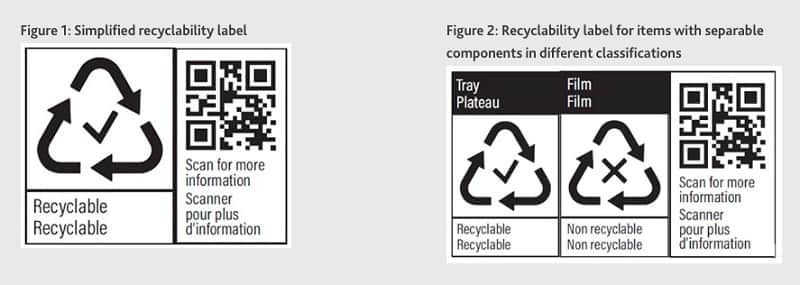

The product’s labeling requirements would be determined by the results of this assessment. If all plastic aspects or components of the packaging fall into the same classification, a simplified label can be used. However, if the packaging contains multiple components that can be separated, and these components fall into different classifications, a more detailed version of the label is needed.

In addition to the labeling requirements mentioned above, the labels must include a QR code that links to a website providing Canadians with information about the product’s recyclability. The website would have to meet specific content and formatting requirements.

- Compostability:

The proposal also prohibits labeling items with the terms “degradable” and “biodegradable” or any variation of those terms that imply break down, fragmentation, or biodegradability in the environment to reduce consumer confusion.

For an item to be labeled “compostable,” it must be certified by an accredited third party to a suitable standard specification for compostable plastics. Compostable products would also need to be tested in-field at a composting facility in Canada, associated with organic wastes, and meet specifications related to concentrations of metals, fluorine, and other elements of concern. Anti-UV-PET – Chemical recycling

Regarding labeling, compostable items would be classified as “non-recyclable,” display the word “compostable” (with qualifying language regarding industrial composting facilities), and use green coloring, striping, or tinting to differentiate it from non-compostable plastic items.

The proposal also mandates that Price Look-Up (PLU) produce stickers be compostable and prohibits PLU produce stickers that are non-compostable. However, PLU stickers are exempt from the specific wording/coloring requirements.

-TotalEnergies has expanded its operations in Europe in the field of plastic recycling by acquiring Iber Resinas, a company based in Spain that engages in the mechanical recycling of plastics for sustainable applications

Through this acquisition, TotalEnergies will increase its production of circular polymers in Europe, broaden its range of recycled products, and enhance its access to feedstock through Iber Resinas’s network of suppliers. Anti-UV-PET – Chemical recycling

Iber Resinas recycles plastics such as polypropylene, polyethylene, and polystyrene derived from household and industrial waste in its two plants located near Valencia, Spain. It also sells its products to direct customers who use them for the production of automotive parts, packaging, or building materials.

TotalEnergies aims to increase the share of circular polymers in its plastics production to 30% by 2030 and believes that the acquisition of Iber Resinas is an important step towards achieving this goal.

The company’s subsidiary Synova is already a leader in the production of recycled polypropylene for sustainable applications for the automotive and construction industry in France.

TotalEnergies is also involved in advanced recycling and bioplastics and is a founding member of the Alliance to End Plastic Waste, a global initiative aimed at eliminating plastic waste in the environment. Anti-UV-PET – Chemical recycling

According to Nathalie Brunelle, Senior Vice President Polymers, Refining & Chemicals, at TotalEnergies, the acquisition of Iber Resinas will enable the company to combine the recycling know-how of Iber Resinas with TotalEnergies’ polymers expertise.

Santiago Sanz and Borja Sanz, owners and managing directors of Iber Resinas, also expressed their satisfaction with the acquisition, stating that it would enable them to strengthen and develop Iber Resinas while meeting the new challenges and ambitions of their customers.

Overall, TotalEnergies’ acquisition of Iber Resinas is part of its commitment to promoting the circular economy in the use of plastics and reducing the environmental impact of plastic waste.

-Avient Corporation has unveiled ColorMatrix Ultimate UV390R, a novel additive technology that offers ultraviolet (UV) light safeguarding for both original and reused polyethylene terephthalate (rPET) resin

ColorMatrix Ultimate UV390R, which is part of the Ultimate portfolio, is particularly beneficial for rPET with high levels, as it offers protection against UV rays that permit less than 10% UV light transmission up to 395nm, or the limit of the perceptible spectrum, to shield the contents from deterioration.

This innovative technology also provides several advantages when using rPET, such as enhancing bottle mechanical strength to improve bottle-blowing performance, lowering bottle blowouts and stoppages, and decreasing weight.

The reheat performance of the additive technology can also be enhanced, resulting in a decrease in carbon emissions during bottle-blowing.

Furthermore, this technology supports better recyclability by reducing the yellowing of rPET during subsequent heat histories.Anti-UV-PET – Chemical recycling

UV light can harm beverages and personal care products by deteriorating sensitive ingredients such as micronutrients, vitamins, and product emulsifiers, reducing the quality and shelf life of these products.

Plastic packaging used for these items often requires an efficient UV barrier that ideally permits less than 10% UV light transmission up to 395nm, or the edge of the visible spectrum, to protect the contents and prolong their shelf life.

When selecting performance additives for packaging, brand owners and manufacturers usually look for solutions that can aid them in achieving their goals for a circular economy and complying with regulations and directives on rPET content without jeopardizing efficiency.

-LyondellBasell may build next chem recycling plant in Houston

LyondellBasell may build its second chemical recycling plant at its refinery in Houston, one of the several plans it is considering for the site after the company shuts down the complex, the producer said.

LyondellBasell plans to build its first commercial-scale chemical recycling plant at its Wesseling site near Cologne, Germany. The project will use LyondellBasell’s MoReTec process technology, which is already featured in a semi-industrial-scale chemical recycling plant in Ferrara, Italy. A final investment decision for the Wesseling project is expected by the end of 2023.Anti-UV-PET – Chemical recycling

Much of the waste for the Wesseling plant will come from a plastic-waste sorting and recycling facility that is being developed by Source One Plastics, a joint venture made up of LyondellBasell and 23 Oaks Investments.

If LyondellBasell decides to develop the Wesseling site, then the Houston refinery could host the company’s second chemical-recycling plant, said Peter Vanacker, CEO. He made his comments during an earnings conference call. Vanacker had mentioned chemical recycling at the Houston refinery a year ago.

The refinery has hydrotreaters that could upgrade the pyrolysis oil produced by the chemical recycling plant.

-Russia’s economic recovery: it will grow more than Germany and Great Britain

According to the latest forecasts of the International Monetary Fund, this year Russia will grow more than Germany and Great Britain and like France and Italy.

Vladimir Putin’s state is expected to match, if not surpass, four of the Western powers that are insisting on sanctions against Moscow, which was responsible for starting the war in Ukraine last year.

This economic recovery by Russia therefore represents an unexpected event. In 2022 Putin hoped for a blitzkrieg in Ukraine, via a blitzkrieg in the country, but the West had responded with sanctions to limit Russia.

Mario Draghi, Italian premier at the time, had been one of the most determined leaders, in favor of the embargo of Russian energy sources, asking himself: “What do we prefer? Peace … or the air conditioning on all summer?”. Anti-UV-PET – Chemical recycling

Russia will grow more than Germany and Great Britain: Putin continues the war in Ukraine Despite the crushing sanctions, Russia appears to be continuing to grow economically and, as if this weren’t enough, Putin continues his war on Ukraine undaunted.

It seems that the Russian oligarchs did not do much to make the Russian president think, but rather supported him and, at the same time, tried to make other countries believe they did not appreciate the decisions of the former KGB.

Do Sanctions Work? Not entirely it seems As Federico Fubini points out in an article published in the Corriere, it is now clear that the most optimistic forecasts on the impact of the sanctions on Russia have not finally come true.Anti-UV-PET – Chemical recycling

Indeed, ironically, countries such as Singapore, Malaysia, China and India have intensified economic relations with Moscow and several Western countries have increased the import of petroleum products that emerging countries derive from crude oil from Moscow.

-TSMC also wants to produce car chips in Europe

The Taiwanese giant discusses the construction of a factory in Germany. A 10 billion euro investment is ready

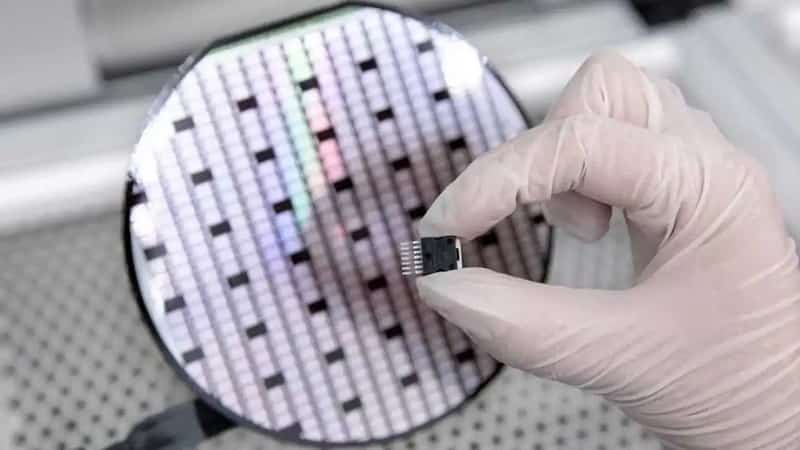

Taiwan Semiconductor Manufacturing Company (TSMC) may soon open a chip manufacturing plant in Europe.

The Asian giant, in fact, has negotiations underway with a series of partners to kick off a maxi investment of between 7 and 10 billion euros for a microchip plant in Germany and more precisely in Saxony. Anti-UV-PET – Chemical recycling

The plant, which would be operated by a joint venture between TSMC, NXP Semiconductors, Bosch and Infineon Technologies, would focus on the production of chips for the automotive sector and would receive state subsidies, for which approval from the European Commission is required .

Plans could still change

“TSMC is still evaluating the possibility of building a plant in Europe,” said company spokeswoman Nina Kao, without providing further details.

Representatives from NXP, Bosch, Infineon and the German economy ministry instead directly declined to comment on the project.

TSMC chairman Mark Liu said it has begun assessments of setting up manufacturing operations in Germany, Europe’s largest economy.

According to CEO C. C. Wei, the proposed European plant would focus on the production of 28-nanometer chips for the automotive sector.

Similar projects in Germany have received grants of up to 40% of the total amount allocated. Anti-UV-PET – Chemical recycling

These are measures put in place by the EU with a view to doubling its share of global semiconductor production by 2030.

Production of silicon carbide chips in a Bosch plant

A helping hand from the EU

In April, Europe approved the Chips Act, a €43 billion measure to boost domestic production following supply chain disruptions during the pandemic and rising tensions between the United States and China.

Meanwhile, in Japan, where TSMC is investing $8.6 billion with partners to build an additional plant, the Taiwanese company will receive about half of the funding from the government.

Strategic move

If built, it would be TSMC’s first plant in the European Union. TSMC is Taiwan’s largest corporation and the main chip maker for Apple. It produces most of its semiconductors in Taiwan, but as customers and governments grow increasingly concerned about geopolitical tensions and China’s military threats against the island, it has begun ramping up its capacity in the United States and Japan. Anti-UV-PET – Chemical recycling

Infineon, on the other hand, opened a semiconductor factory in Dresden, Saxony on Tuesday, a city that also hosts production plants for GlobalFoundries and Bosch. Manufacturing plants are concentrated in clusters, allowing expensive plants to take advantage of infrastructure and workers that are already on site.

-Coca-Cola switches to 100% rPET in Italy

With the new Gaglianico plant coming on stream, the bottles of Coca-Cola, Fanta, Sprite, Kinley, Powerade and FuzeTea are now entirely in recycled PET.

Cola has announced the switch to 100% recycled PET (rPET) bottles for all its brands distributed on the Italian market, including therefore the drinks Fanta, Sprite, Kinley, Powerade and FuzeTea. Anti-UV-PET – Chemical recycling

This result was possible thanks to the recycling capabilities of the new CCH CircularPET plant in Gaglianico (BI), costing 30 million euro (read the article), put into operation as part of the World Without Waste plan.

Previously a bottling plant, which was later shut down for eight years, the plant was renovated and since July last year has been able to transform up to 30,000 tons of PET flakes a year, first into preforms and then into new bottles in 100% recycled PET .

The new Biella plant is capable of producing 9 different types of preforms, both for carbonated and still drinks, with a weight ranging from 17 to 44.7 grams for bottles with capacities from 0.4 to two litres.

“We were the first soft drinks company to introduce a bottle made with 100% rPET to the Italian market and we have been committed for years to reducing the raw material in glass, aluminum and plastic packaging,” Coca-Cola HBC said in a statement.

We have recently extended the ‘tethered caps’, the caps attached to the bottle, to all brands in the portfolio, with the aim of simplifying collection and recycling and reducing the dispersion and impact of plastic on the environment”.

coca cola gaglianico PETAs part of the World Without Waste programme, the beverage giant has eliminated the color of the bottles of Fanta (orange) and Sprite (green) to facilitate recycling in the flows of transparent PET.

KeelClip paper secondary packaging was also introduced for can multipacks.

Finally, a collaboration was launched with the Coripet consortium and IED – Istituto Europeo di Design to involve young designers in a path dedicated to sustainability, stimulating the new generations on the topic of the circular economy of PET and the importance of recycling. Anti-UV-PET – Chemical recycling

This will take place through a contest for the creation of a Recycling Machine with an innovative design from an aesthetic and experiential point of view.