Aramid Automotive Recycling Duties 30-10-2021 - Arhive

Aramid Automotive Recycling Duties

-Teijin Aramid demonstrates potential of circular high-performance fibers

Teijin Aramid, a world leader in aramid, has achieved yarn-to-yarn recycling for its flagship product Twaron®. The organization is now partnering with FibreMax and Hampidjan to demonstrate the performance of the resulting circular Twaron® fiber. Aligning with Teijin Aramid’s belief in taking responsibility for the environmental impact of its material flows, this development is a key step toward its goal of supplying fully circular high-performance fiber.

For more than 20 years, Teijin Aramid has been recycling aramids such as its Twaron® fiber into pulp, which is then used in automotive brake pads and gaskets. Now, for the first time, its Research and Innovation Center in Arnhem, the Netherlands, has successfully achieved yarn-to-yarn recycling using feedstocks from end-of-life materials.

Several hundred kilograms of Twaron® yarn have now been produced from materials of various recycling statuses. The properties of this circular Twaron® fiber are excellent, and its performance is equal to that of standard Twaron® fiber. Teijin Aramid has a patent pending for this breakthrough technology.

Performance testing in real-life

Teijin Aramid has now partnered with FibreMax, from the Netherlands, and Hampidjan, based in Iceland, to demonstrate the performance in demanding real-life applications. Using the circular Twaron® fiber, FibreMax will produce crane pendants and Hampidjan will produce slings for the offshore and shipping markets. In both applications, Twaron® will make up more than 90% of the final product’s weight. These partners are confident that Teijin Aramid’s new technology will enable circularity in high-performance applications and help to tackle the issue of waste from end-of-life products.

-Avient expands HP materials portfolio with Edgetek Toughened PPA

Avient has introduced its Edgetek Toughened polyphthalamide (PPA) formulations, offering improved heat performance and low moisture absorption versus nylon 66 (PA66) for demanding applications.

The new impact-modified PPA materials are formulated in filled and unfilled grades that deliver exceptional structural integrity and impact resistance at high temperatures. These heat-stabilised formulations maintain tensile strength and tensile elongation properties when tested for long-term thermal aging up to 120°C.

With a slower moisture absorption rate than PA66, they also help to improve durability and long-term performance. Enhanced chemical resistance makes Edgetek Toughened PPA suitable for a range of rigid applications, such as cooling systems, housings, fuel pumps or structural components.

Matt Mitchell, Director, Global Marketing of Specialty Engineered Materials at Avient, said: “This high-performing formulation provides an effective solution for durable, structural applications that need to withstand extreme environments. We’ve combined material science and innovation to expand designers’ ability to solve application challenges.”

Plastics have taken the world by storm over the last century, finding applications in virtually every aspect of our lives. However, the rise of these synthetic polymers, which form the basis of plastics, has contributed to many serious environmental issues. The worst of these is the excessive use of petrochemical compounds and the disposal of non-biodegradable materials without recycling; only 14 per cent of all plastic waste is recycled, which hardly puts a dent in the problem. Aramid Automotive Recycling Duties

To solve the plastic conundrum, ‘circular’ systems need to be developed in which the source materials used to produce the plastics come full circle after disposal and recycling. At Tokyo Institute of Technology, a team of scientists led by assistant Professor Daisuke Aoki and Professor Hideyuki Otsuka is pioneering a novel concept. In their environmentally friendly process, plastics produced using biomass (bioplastics) are chemically recycled back into fertilisers.

The team focused on poly (isosorbide carbonate), or ‘PIC’, a type of bio-based polycarbonate that has garnered much attention as an alternative to petroleum-based polycarbonates. PIC is produced using a non-toxic material derived from glucose called isosorbide (ISB) as a monomer. The interesting part is that the carbonate links that join the ISB units can be severed using ammonia (NH3) in a process known as ‘ammonolysis’. The process produces urea, a nitrogen-rich molecule that is widely used as a fertiliser. While this chemical reaction was no secret to science, few studies on polymer degradation have focused on the potential uses of all the degradation products instead of only the monomers.

-China asks US to create conditions to push phase-I of trade deal

China and the United States should join hands to create conditions to implement the first phase of the US-China economic and trade agreement signed in January last year as that can be mutually beneficial as well as benefit the rest of the world, according to China’s commerce ministry, which delineated key tasks to grow its trade in services during the 14th Five-Year Plan period (2021-25).

China would welcome a move by the United States to start a targeted tariff exclusion process while keeping open the potential for additional exclusion processes, ministry spokeswoman Shu Jueting recently told a media briefing.

“China always believes lifting additional tariffs is in line with the interests of consumers and producers in both countries and also is good for global economic recovery,”Shu said, adding economic and trade teams of the two countries have been maintaining normal communication, and her ministry will release news on any new information.

The tasks include deepening reform and expanding opening-up, accelerating digitalization, optimizing industry structure and regional layout, supporting market players, and enriching cross-border cooperation, according to a new development plan released by 24 government departments, including the ministry of commerce and the National Development and Reform Commission, the country’s top economic regulator, she was quoted as saying by Chinese media reports. Aramid Automotive Recycling Duties

The plan has included digital trade for the first time to align with the development trend of digitalised, Internet-based and intelligent services trade, she said.

-EU packaging waste rises almost 80 million tonnes in a decade, report finds

Eurostat, the data analysis wing of the European Commission, recently published statistics on packaging waste in the 27 European Union (EU) Member States, as well as some non-member countries. The report summarises the developments between 2009-2019, the period for which official reporting on packaging waste for all EU Member States was implemented.

PackagingThe report sets the total volume of packaging waste generated in 2019 at 79.3 million tonnes – an increase of 2.4 per cent compared to the previous year. Eurostat attributes this rise to an increase in packaging made from glass and plastic, which saw a 4.7 and 3.6 per cent increase 2018-2019, respectively.

Over the ten year period, paper and cardboard accounted for the majority of packaging waste material generated, contributing 32.2 million tonnes to the total packaging waste generated in 2019, the waste stream growing by 23.3 per cent since 2009. The report also notes that plastic packaging material reached a total of 15.4 million tonnes, increasing by 25.8 per cent over the same period. Glass had a volume of 15.2 million tonnes, followed by wood packaging (12.4 million tonnes), and metal packaging (4 million tonnes).

Eurostat’s findings also observe an increase of 2.4, 1.5, and 0.3 per cent per inhabitant in packaging waste generation, recovery, and recycling, respectively. Between 2009-2019, the amount of packaging waste generated per inhabitant substantially increased by 18.3 per cent, with recycling and recovery volumes increasing even more over the same period, by 22.6 and 26 per cent, respectively.

The report highlighted the progress of EU member states towards the targets set out in Article Six of the Packaging Waste Directive. The Directive requires member states to achieve a 60 per cent recovery rate (including waste incineration), a minimum 55 per cent recycling rate for packaging waste, a 60 per cent minimum recycling rate for glass, paper, and cardboard, as well as recycling rates of 50, 22.5, and 15 per cent for metals, plastics, and wood, respectively.

-US issues final duties ruling in polyester yarn anti-dumping probe

The US Department of Commerce has announced its final determinations that imports of polyester textured yarn from four nations are being unfairly sold below their fair value in the US.

The four nations detailed in The Department of Commerce’s polyester yarn antidumping investigation are Indonesia, Malaysia, Thailand and Vietnam.

The Department of Commerce calculated antidumping duty (“AD”) cash deposit rates that ranged from 2.58% to over 56%. As a result of the final determinations, US Customs and Border Protection will continue to collect antidumping duties in the amount equal to the final dumping cash deposits rates for imports from each producer or country (i.e., the “all others rate”). Aramid Automotive Recycling Duties

The news follows the result of an investigation in June which found four nations have been selling polyester yarn imports in the US at a price that harms domestic makers.

The investigation was prompted after two major US synthetic yarn producers – Unifi Manufacturing, Inc and Nan Ya Plastics Corporation, America – filed petitions with the Commerce Department and the US International Trade Commission (USITC) in October 2020 alleging that dumped imports of polyester textured yarn from Indonesia, Malaysia, Thailand, and Vietnam are causing material injury to the domestic industry.

The Commerce Department initiated the investigations in November 2020, and the USITC preliminarily determined in December 2020 that imports from the four countries are causing injury to the US domestic industry.

The next step in the trade cases will be the US International Trade Commission’s (the “USITC”) final determination of whether imports from the four countries are a cause of material injury or threaten to materially injure domestic polyester textured yarn producers. The USITC is currently scheduled to announce its final determination on 30 November 2021.

-Austrian Plastic Packaging Giant Invests in Kansas City Region

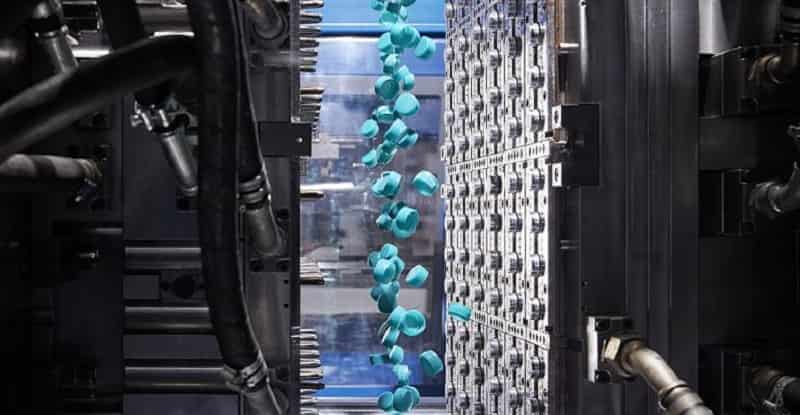

The new 23,000-square-meter manufacturing plant is a key element in Alpla Group’s expansion of injection molding capabilities.

Austria’s plastic packaging powerhouse Alpla Group has picked the Kansas City region for its new 23,000-square-meter manufacturing plant. It represents a key element in its commitment to the expansion of its injection molding capabilities, the company said in today’s announcement.

As one of the global leaders in packaging solutions, the site will enhance Alpla’s scope of innovation and help meet demand of recent business, the company said. The new addition at the Blue River Commerce Center in Kansas City, MO, will be its fourth site in Missouri and the first one dedicated to injection molding. Cutting-edge technologies will be applied to the production of innovative packaging systems, bottles, caps, and injection-molded parts for a range of industries. Led by Cushman & Wakefield, the project is slated to begin in late 2021, with a completion date in the fourth quarter of 2022. The plant is expected to create 75 jobs, as the company continues to invest in the city over the next several years.

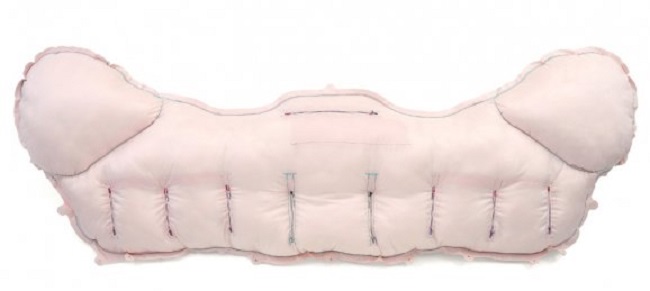

-Exterior airbag prevents head injuries

The airbag covers the rigid parts of the vehicle where the likelihood of fatal injury is the highest.

Automotive components and parts supplier Toyoda Gosei, headquartered in Kiyosu, Japan, has developed a pedestrian protection airbag that will protect the head of anyone hit hit by a vehicle.

Among traffic accidents in Japan, the highest mortality rate is seen in those involving pedestrians. The main cause of death in these accidents is head injury.

The pedestrian protection airbag covers the rigid parts of the vehicle, such as the front pillars, where the likelihood of fatal injury is the highest. The internal pressure is adjusted to the optimum level for each part of the vehicle covered, mitigating impacts to the head.

The new airbag will first be used on the Subaru Legacy Outback models for Japan which has just been launched.

Aramid Automotive Recycling Duties