Auomotive Thermoplastic Composite Material 29-09-2021 - Arhive

Auomotive Thermoplastic Momposite Material

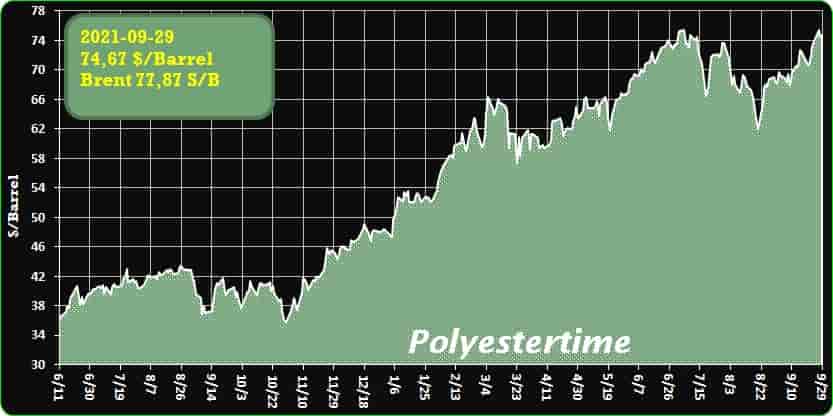

Crude Oil Prices Trend

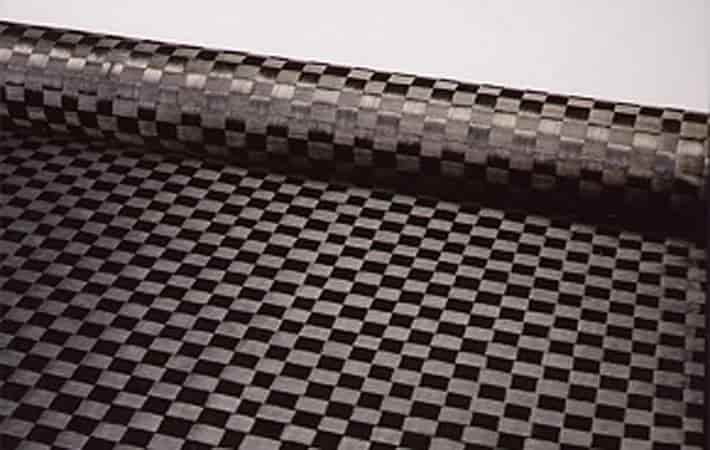

-Japan’s Mitsubishi Chemical unveils thermoplastic composite material

Mitsubishi Chemical and Mitsubishi Chemical Advanced Materials Japan (MCAM) have announced the development of a thermoplastic composite material (FRTP) which offers flame retardancy, high production performance, and recyclability. Mitsubishi Chemical is a chemical producer, supplying different sectors from automotive and electronics to medical and sport.

Today, electric vehicles (EVs) are widely being developed with zero emissions to combat climate change. Two fundamental aspects of the EV battery systems are the requirement of higher fire resistance for passenger’s safety and utilising lightweight materials to further save energy. Conventional technologies have often applied thermoset plastic composites, which have flame retardancy and are lightweight. However, low recyclability and less production performance are often considered issues, Mitsubishi said in a media statement.

Mitsubishi and MCAM have together solved these issues in the development of FRTP by bring together our technology about battery systems and optimizing our unique fibres and thermoplastic resin compositions and achieving fire resistance that withstands more than five minutes of a flame over 1000? in our experiment. Mitsubishi and MCAM have already commenced sample work for some customers, and aim to develop new applications such as battery enclosures.

-Plastics Urges Industry to Voice Opposition to Virgin Resin Tax

The proposed 20-cent-per-pound tax on virgin resin could put 163,400 jobs in the plastics industry at risk.

Calling this an “all-hands-on-deck moment,” Plastics Industry Association (PLASTICS) President and CEO Tony Radoszewski is urging members of the plastics industry to voice their opposition to the 20-cent-per-pound tax on virgin resin that is bouncing around Congress. PLASTICS has set up a web page that will allow anti-taxers to send a message via email to their senators and member of Congress in a few quick clicks.

In just a few short weeks, the plastic tax has gone from just an idea, writes Radoszewski, “to a full-fledged campaign by environmental activist organizations like Greenpeace and Oceana.” Auomotive Thermoplastic Momposite Material

The legislation was introduced by Senator Sheldon Whitehouse (D-RI), who sits on the Senate Finance and Environment and Public Works committees, in early September. It calls for a 10-cent-per-pound tax in 2022 paid by manufacturers, producers, and importers of virgin plastic resins. It would increase incrementally to reach 20 cents per pound in 2024. As noted in a recent article in PlasticsToday, the proposal includes a number of exemptions, including for medical products.

In a statement released late last week, PLASTICS Chief Economist Perc Pineda noted that the resin tax potentially puts 163,400 jobs in the plastics industry at risk, not including jobs in the plastics-related supply chain that over time would also be affected.

-Evian Loop bottle to debut in South Korea

Water brand Evian has launched a recycled PET prototype bottle using ‘advanced’ recycling technology from Canada’s Loop Industries.

The ‘transformational’ technology allows no and low value PET to be recycled “endlessly” into new, virgin-like PET, claims Loop Industries. The process breaks plastics down into its base building blocks, or monomers, which are then purified and repolymerised into Loop PET. Auomotive Thermoplastic Momposite Material

Branded as ‘Evian Loop’ bottles, the prototype is the culmination of a four-year partnership between the two companies, and a commercial rollout is forecast for South Korea in 2022. This will allow Evian to recycle and repurpose more and more existing plastics waste, bringing the company one step closer to its 2025 circularity objective.

“By partnering with Loop Industries, we can look to accelerate our drive to keep the use of virgin plastics to an absolute minimum, whilst also preserving the uniqueness and purity of our natural mineral water,” said Shweta Harit, vice president of marketing for Evian.

-New pledge for zero impact from textile fibre fragmentation by 2030

Sophie Mather, executive director of UK-based The Microfibre Consortium (TMC), recently unveiled a new global commitment to achieve zero impact from fibre fragmentation from textiles to the environment by 2030. The fashion industry has made tremendous strides in understanding the root causes of the problem and it is time for it to expedite solutions to ensure actual impact, she said.

The Microfibre Consortium (TMC) facilitates the development of practical solutions for the textile industry to minimise fibre fragmentation and release to the environment from manufacturing and the product life cycle.

“There is an urgent need to position this topic within the larger sustainability agenda and enable a no-regrets decision to be made,” Mather said last week .

Up until now, Mather said, stakeholders have not had a ‘distinct global agenda’ within which to work, which means that research funding has not been allocated in sufficiently strategic ways that can deliver coherent results and promote progress. The Microfibre 2030 Commitment and its accompanying Roadmap seek to change that. Auomotive Thermoplastic Momposite Material

-Trinseo & Indaver Announce Offtake Agreement for Recycled Styrene

Companies pursue long-term business collaboration

Trinseo a global materials solutions provider and manufacturer of plastics and latex binders, and Indaver, a leader in sustainable waste management in Europe, have signed an offtake agreement for recycled styrene (r-styrene).

Under the terms of the agreement, Trinseo will buy a minimum of 50 percent of the r-styrene produced at Indaver for a 10-year period, following startup of the plant planned in 2023. Auomotive Thermoplastic Momposite Material

As with its other waste collection processes, Indaver will collect post-consumer polystyrene (PS), such as yogurt pots and single-use packaging, and recycle and produce the r-styrene through a proprietary depolymerization technology at its Antwerp, Belgium site. The r-styrene will then be sent to Trinseo’s Tessenderlo, Belgium site nearby and will be used to manufacture recycled PS resins for dairy packaging and other applications. Both the r-styrene and r-PS products will be ISCC Plus mass balance certified.

Recycled PS has the exact same properties as PS made with virgin fossil-based material. Because of the simple chemical structure of PS, infinite recycling has become a reality, and its purity makes it an ideal material for food packaging. Trinseo recently launched rPS, STYRONTM CO2RETM CR55 PS Resins for food contact applications early this year. This particular product has been used to make the first yogurt pot made with a food contact compliant polystyrene recyclate for a leading European yogurt brand, which has been on shelves in France since May 2021.

-MEG prices in Asia increased by 5%

Monoethylene glycol (MEG) prices in Asia rose 5% on September 27 amid rising naphtha prices and reduced supplies caused by Chinese authorities’ policy to control and restrict capacity in the country, ICIS reported.

MEG spot deals were concluded at USD762-770 per tonne, CFR at the main ports of China (CMP). MEG spot prices as of September 24 were USD728-735 per tonne, CFR CMP. Auomotive Thermoplastic Momposite Material

Asian naphtha prices are rising on the back of rising global crude oil futures amid support for demand for petrochemicals.

ICE Brent crude futures rose more than USD1 a barrel to USD79.40 a barrel at noon in Asia as global production disruptions forced energy companies to withdraw large volumes of oil from inventories.

Offerings from sellers continued to rise in an effort to recoup margins, although buyers and end users were generally cautious amid the market’s surge.

On the supply side, China’s MEG production declined amid China’s dual-control policies to reduce emissions, coupled with capacity constraints caused by limited coal supplies.

“Tough measures to restrict production in industries with high energy consumption could last until the end of the year,” said a regional trader.

Earlier it was reported that the total stocks of monoethylene glycol (MEG) in the east of China increased last week by 5.9% compared with a week ago due to an increase in the number of arriving shipments of imported material in ports. Thus, this figure on September 10 amounted to 621.3 thousand tons. Meanwhile, on September 3, it was at the level of 586.5 thousand tons.

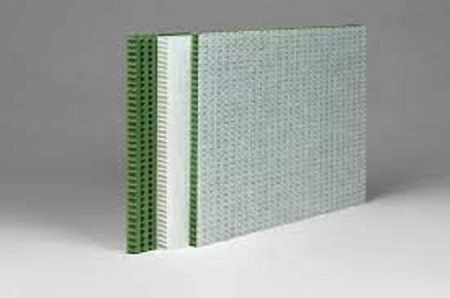

-EconCore’s RPET honeycomb technology accredited with prestigious Solar Impulse Label

EconCore, the world leader in technologies for economic honeycomb sandwich material production was recently awarded the Solar Impulse Label in recognition of the sustainability of their RPET honeycomb core technology.

EconCore has developed a continuous manufacturing process that can produce thermoformable, high-performance lightweight panels with a thermoplastic core made from recycled PET, in a cost-effective way. RPET honeycomb core made of 95 recycled PET, mainly sourced from post-consumer waste including (food) packaging, PET bottles, textiles and post-industrial waste.

With the RPET EconCore honeycomb cores and panels, customers can benefit of easier implementation, faster functionalization, and can design lighter structures which translates into significant CO2 reduction.

EconCore’s technology is used in a wide range of applications including automotive, transportation, building and construction, industrial packaging/graphical displays, furniture and many others. Auomotive Thermoplastic Momposite Material

-Reduce, reuse, compost: Why recycling alone won’t solve the plastic crisis

About 8 billion tons of plastic has been produced globally since the 1950s, but only 10% has actually been recycled.

Recycling is increasingly seen as an unsuitable solution to the growing volume of food waste produced by the world. Auomotive Thermoplastic Momposite Material

In addition to reducing our overall consumption levels, addressing the waste crisis will require more support for new forms of packaging such as those made from compostable materials.

In 1970, packaging manufacturer Container Corporation of America was on the hunt for a new symbol to help companies showcase a commitment to recycling. University of Southern California architecture major Gary Anderson spent just two days designing the entry that would come out on top of a field of 500. The winning three-arrow symbol was awarded $2,000 in prize money and was released into the public domain.

-ISO standard launched to quantify drapability and deformability of fabrics and nonwovens

ISO 21765 allows worldwide comparable measurement of various parameters, which can be measured on Textechno’s DRAPETEST instrument.

A newly developed international standard for quantifying material behavior in terms of drapability and deformability was recently published by ISO as ISO 21765:2020, according to precision testing equipment supplier Textechno (Mönchengladbach, Germany) and non-crimp fabrics (NCF) supplier Saertex (Saerbeck, Germany, and Huntersville, N.C., U.S.). Auomotive Thermoplastic Momposite Material

According to the partners, the new standard ISO 21765 allows the worldwide comparable measurement of all relevant parameters regarding the deformability and drapability of all kinds of fabrics, including woven fabrics and NCFs as well as knitted fabrics and nonwovens on Textechno’s precision testing equipment DRAPETEST. This shows potential for recycled carbon fiber nonwovens.

-New recycling plant promises more sustainable bedding

Dow Polyurethanes and Orrion Chemicals Orgaform, together with Eco-mobilier, H&S Anlagentechnik and The Vita Group, have inaugurated a pioneering mattress recycling plant as part of the RENUVA circular economy programme.

Old mattresses made of polyurethane (PU) foam will now be recovered, dismantled and chemically recycled to create a new polyol, a key starting material to produce PU. This RENUVA polyol is designed for various applications including mattresses.

Dow states that this is a major step forward for the recovery and recycling of PU foam, and a significant advance for closing the loop for end-of-life mattresses. At full capacity, the plant will process up to 200,000 mattresses per year, helping to tackle the growing mattress waste problem. Auomotive Thermoplastic Momposite Material

“We are immensely proud to have unveiled this plant,” commented Marie Buy, sustainability leader EMEAI, Dow Polyurethanes.

Auomotive Thermoplastic Momposite Material