Bacteria Petrochemicals PlasticPollution 07-07-2021 - Arhive

Bacteria Petrochemicals PlasticPollution

Crude Oil Prices Trend

-Manufacturer Of Recycled Material Econyl Launches Online Fashion Store

Aquafil, the synthetic fabric manufacturer behind regenerated nylon fabric Econyl, has launched a consumer-facing e-commerce shop on its website.

The online marketplace stocks womenswear, menswear, swimwear and accessories from 15 brands who make products using Econyl. More brands are expected to join the site in the coming months.

The Italian company said it has created the store to respond to market trends of sustainability and online sales. “2020 was a very peculiar year but, because of it, we had time to slow down and think about what Aquafil’s future looks like. After a lot of brainstorming, we came to the idea that we needed to step out of our comfort zone and move forward in our supply chain to reach the end consumer. Hence, we came up with the idea to transform our site into a digital market, to give consumers the opportunity to find products made in Econyl offered by brands that share our values and our commitment to a better world. It is a long-term project which we strongly believe in but we are also aware that we have a lot to learn when navigating the B2C world,” a spokesperson said.

Econyl is made from recycled waste, including fishing nets, carpet and industrial plastics, and is regenerable an infinite number of times. It has become a popular new fabric in recent years as brands switch to more environmentally-friendly fabrics. It has been used by Burberry, Prada, Adidas and Speedo, though these brands are not currently available on the new shop.

-Thailand’s IVL to build PET recycling plant in Indonesia

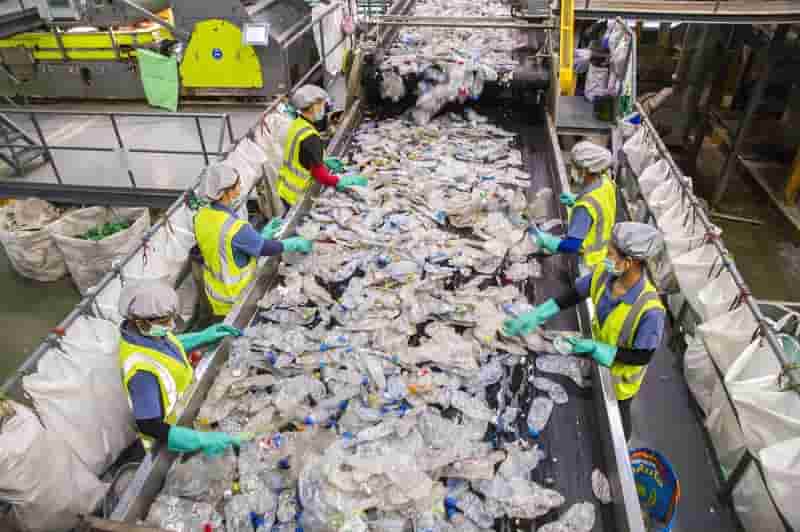

Indorama Ventures Ltd (IVL) is building a new polyethylene terephthalate (PET) plastic bottle recycling plant at Karawang in west Java, Indonesia, the Thailand-listed producer said on Tuesday. Bacteria Petrochemicals PlasticPollution

The facility is expected to start up in 2023 and will recycle 1.92bn PET plastic bottles annually in support of the Indonesian government’s plan to reduce ocean debris, the company said in a statement.

Investment details in the new recycling plant were not disclosed.

The recycling plant will provide the washed and shredded post-consumer bottles as PET flake feedstock to produce recycled resin suitable for food applications, IVL said.

Indonesia is aiming to reduce 70% of its 2017 plastic debris by the end 2025.

PET plastic, commonly used in bottles, is 100% recyclable and the most collected and recycled plastic packaging in the world, IVL said.

“Giving waste an economic value as feedstock for new bottles, also drives improvements in waste collection systems,” said D K Agarwal, CEO of IVL’s combined PET, integrated oxides and derivatives (IOD) and fibres business.

As announced in 2019, IVL aims to recycle a minimum of 750,000 tonnes of PET globally by 2025, with a planned investment of up to $1.5bn.

-VSF: rising price like an arrow on the bowstring

VSF companies at the beginning of this year were complacent and ready to regain lost ground by pushing up prices significantly. VSF price in the first two months rose by around 4,000yuan/mt, with the higher hitting 16,000yuan/mt. However, further spread of the COVID-19 in the second quarter like a basin of cold water extinguished the small flame that was just ignited by VSF.

VSF started to keep falling subsequently by around 3,000yuan/mt from 15,300-15,800yuan/mt to 12,300-12,800yuan/mt and sales continued to increase, while inventory kept going up. The price tool did not seem to work properly. Even if VSF plants signed a considerable number of orders by slashing offers, the slow implementation can hardly reduce VSF inventory. Bacteria Petrochemicals PlasticPollution

The performance of other fibers is remarkable in the meantime. Cotton products driven by the new national trend are vibrant on the market, and the profit is relatively satisfactory. Polyester products whose price declined fast in Mar were favored by customers by virtue of low price and the market recently climbed up underpinned by crude oil. Bacteria Petrochemicals PlasticPollution

The embarrassment of VSF has become more prominent recently as the price gap with cotton has widened to almost 4,000yuan/mt and yarn mills gradually start to suffer losses. The lower price of vortex-spun R30S had touched 15,600yuan/mt, while processing cost is just above 3,000yuan/mt, leading to losses and fast reduction of pure spun rayon yarn machines. The supply of vortex-spun rayon yarn supply starts to decrease accordingly and yarn mills whose pressure has been alleviated began to raise offers last week.

-Next generation smart shirt powered by 5G

A combination of bio parameters that have never before all been detected by textile sensors is enabled. Bacteria Petrochemicals PlasticPollution

ZTE and its Italian partners introduced the 5G-enabled YouCare smart shirt at the Mobile World Congress 2021 held in Barcelona, Spain, from June 28th to July 1st.

As a Chinese provider of advanced telecommunications systems, mobile devices and enterprise technology solutions, ZTE sells its products and services in more than 160 countries and is listed on the Hong Kong and Shenzhen stock exchanges.

According to a recent report, Challenges and Prospects for China’s Telecommunications Industry and Intellectual Property Market by investment management company Jones Lang LaSalle (JLL), it is among the largest developers of global 5G standards with a patented technology value of around $7 billion.

As a new remote health monitoring technology, the YouCare smart shirt is said to enable the detection of a combination of bio parameters that have never before all been detected by textile sensors, such as a “real” electrocardiogram, a respiratory act analysis, the components of sweat, muscle effort and body temperature.

-New ECOSENSOR collection pairs comfort and performance

The vision that lies behind ECOSENSOR™ is bold and ambitious: to keep nature, body and mind in perfect harmony. This ideal concept turns real in a versatile collection of eco – high-tech fabrics that embody new generation values of design, innovation and responsibility. Bacteria Petrochemicals PlasticPollution

For its new S/S 2022 collection, ECOSENSOR™ by Asahi Kasei has concentrated all its key values into a nature-driven and high-tech fabric collection that has versatility is at the core. A diversified range of technologies from circular knits to woven fabrics in different textures and finishing created to meet the different needs of the contemporary consumer who is looking for performance, durability, wellbeing together with responsible values.

In this sense, ECOSENSOR™ gathers many dimensions: sustainability, active climate control, exquisite touch, lightness, comfort and extreme performance that together co-habit the textiles. The commitment in building a totally sustainable offer is tangible and solid, as ECOSENSOR™ has set out to use only certified high-quality recycled materials in order to optimize and value at best the use of NEW resources for all its collection.

-Agilyx plant ‘proof-positive’ of circularity

Chemical recycling pioneer Agilyx has surpassed 16,000 hours of commercial operating hours at its operation in Oregon, USA, marking 4,400 tonnes of converted plastics waste. Bacteria Petrochemicals PlasticPollution

This has been achieved both using mixed waste plastics and with polystyrene, which is the current mode of operation in Tigard, Oregon with the unit now forming part of the Regenyx joint venture with AmSty. Both the mixed waste plastic and the polystyrene waste has been sourced directly by Agilyx utilising the feedstock management programme that has since been incorporated into the Cyclyx Joint Venture.

This significant operating milestone equates to the weight of around 20 Statues of Liberty being diverted from landfills and oceans, claims Agilyx.

-How does polyester fabric impact the environment

Polyester has a generally negative impact on the environment. From its production to its use to its disposal, this fabric has unfortunate environmental impacts at every stage of its use cycle. Bacteria Petrochemicals PlasticPollution

To derive the basic materials used in the production of polyester, it’s necessary to obtain fossil fuels, which are limited resources that are also used for vital energy and plastics production applications. The process of refining crude oil into petroleum introduces various toxins into the environment, which can harm living things both in the water and on land.

Once refineries have produced petroleum, further refinement processes are required to produce the ethylene that is used to make polyester. These extraction processes are wasteful, and they introduce more toxins into the environment.

The process of transforming ethylene into polyethylene terephthalate fibers produces more harmful synthetic byproducts, and the dyes and treatment processes used by polyester fabric manufacturers may also make their way into the surrounding environment and poison the area’s ecosystems.

Furthermore, the manufacture of polyester often has significant social and cultural costs. The vast majority of polyester producers worldwide essentially engage in slave labor, and polyester workers are exposed to toxic chemicals that may cause neurological damage, cancer, or other potentially fatal conditions. Major polyester manufacturing companies are almost always owned by major international corporations, which enrich themselves while exploiting uneducated people in impoverished countries.

The environmentally harmful impacts of polyester continue as this fabric makes its way into the consumer market. According to a groundbreaking 2014 study, washing polyester fabrics by hand or in washing machines releases tiny synthetic microfibers into the water supply.

While acrylic fabric was found to be the worst offender in terms of microfiber pollution, polyester came in as a close second. Microfiber pollution in the water supply harms the health of marine life, and it also contaminates drinking water in locations all over the world.

-Bacteria In Cow’s Stomach Can Break Down Plastic, Claims Study

- Bacteria in the cow’s stomach produces enzymes that break apart the chemical bonds in this polyester and, scientists have discovered, can break apart the bonds in synthetic polyesters too.

- Since the 1950s, more than 8bn tonnes of plastic have been produced – equivalent in weight to 1 billion elephants – driven predominantly by packaging, single-use containers, wrapping and bottles.

- Given that cow diets contain these natural polyesters, scientists suspected the bovine stomach would contain a cornucopia of microbes to degrade all the plant material. Bacteria Petrochemicals PlasticPollution

Bacteria found in one of the compartments of a cow’s stomach can break down plastic, research suggests. Approximately 25.8 million tons of plastic waste has accumulated on the land and in the sea, about 15% of which is made of polyesters, a kind of plastic commonly used in soft drink bottles and synthetic fabrics.

The discovery of bacteria which are capable of breaking down natural polyesters offers hope for novel methods to tackle plastic pollution and enable plastics to be recycled. As part of their normal herbivore diet, cows eat something called cutin, a natural polyester produced by plants to protect the walls of the plant cells.

-Special issue: Our plastics dilemma

Although plastics have become an essential material, permeating almost all aspects of modern living, many of the inherent properties that make them useful in such a wide variety of applications also make them a serious environmental threat. In a special issue of Science, “Our Plastics Dilemma,” four Reviews, two Perspectives, a Policy Forum, an associated Report and two News features examine a wide range of topics related to plastics and the problems they present. “As for much new technology, their development and proliferation occurred with little consideration for their impacts, but now it’s impossible to deny their dark side as we confront a rapidly growing plastic pollution problem,” writes Science Senior Editor, Jesse Smith. “The time for preventing plastic pollution is long past – the time for changing the future of plastics in our world, however, is now. Bacteria Petrochemicals PlasticPollution

Estimates of the amount of plastic ”

floating at the ocean surface (measured in the hundreds to thousands of metric tons) only represent a small fraction of what is suspected to be annually discharged by rivers worldwide (several million metric tons). This has led some to speculate a large, yet-unidentified plastic sink that could help explain the rapid removal of river-sourced plastics from the ocean’s surface. In the associated Report in this special issue, Lisa Weiss and colleagues show that this missing sink may not even exist.

-Toray Opens Resins Technical Center in Europe

The center in Munich will enable Toray to formulate solutions for its customers in Europe and accelerate global expansion of its plastics business, particularly in automotive applications. Bacteria Petrochemicals PlasticPollution

Japan’s Toray is opening the doors of its Resins Technical Center at its Automotive Center Europe (AMCEU) near Munich. The new facility will support Toray Resins Europe GmbH, which markets and sells high-performance resin compounds.

The main mission is to support customer application development by swiftly providing technical data, assisting with part design optimization through CAE simulation and innovative material and defect analyses and evaluations. With this facility, Toray will address the fast-expanding adoption of digital design for resin products by bolstering long-term durability data and accurate mechanical property data that materials require. It will increase capabilities for advanced simulation of fiber-reinforced parts, notably to factor in their unique anisotropy, said the company.

The Resins Technical Center will offer materials with high tracking performance and heat cycle resistance and provide support analysis on crack prevention. This is to address such issues as cracking from heat cycling during cooling and heating of molded resin products for insulating high-voltage parts with metal inserts. That problem has increased in line with the emergence of electric vehicles.

Bacteria Petrochemicals PlasticPollution