Battery Film – Bio-based thermoplastic 04-03-2023 - Arhive

Battery Film – Bio-based thermoplastic

-Entek, Brückner USA Ink Agreement for Battery Separator Film Production Lines

Agreement is in addition to a previously announced project, which was selected for a Department of Energy grant award.

Entek has signed an agreement with Brückner Group USA to add 18 lithium-ion battery separator film production lines at its facility. Headquartered in Lebanon, OR, Entek is the only US-owned and US-based producer of “wet-process” lithium-ion-battery separator materials. Brückner Group USA, based in Dover, NH, sells, services, and supports the plastics and fiber machinery of Germany-based Brückner Group GmbH in North America.

This agreement is in addition to a project announced earlier that will expand separator production by approximately 1.4 billion square meters annually by 2027.

The project received a $200 million grant from the US Department of Energy through the Bipartisan Infrastructure Law, which allocated $2.8 billion to support the domestic production of electric vehicle batteries and energy storage systems.

The global lithium-ion battery market was valued at $41.97 billion in 2021 and is expected to expand at a compound annual growth rate of 18.1% through 2030, according to a business report distributed by Grand View Research. Battery Film – Bio-based thermoplastic

The adoption of electric vehicles worldwide will drive demand for lithium-ion batteries.

-DAK Americas to shut down Cooper River site

DAK has announced that it will be shutting down its Cooper River, South Carolina, PET site, said the company.

The PET resins operations at the Cooper River site have shut down indefinitely as of 1 March. PET can be compounded with glass fibre for the production of engineering plastics.

We remind, DAK has announced a 10 cent/lb price increase for polyethylene terephthalate (PET) citing an increase in paraxylene (PX) prices effective 1 June 2022. Increases in blendstock values as well as an increase in demand for gasoline in the summer months has put upward pressure on PX prices. Battery Film – Bio-based thermoplastic

This increase in demand for gasoline has resulted in refiners limiting operating rates at their toluene disproportionation process (TDP) units due to higher blendstock and gasoline prices, making it uneconomical to transform toluene into xylenes, including PX.

DAK Americas, Indorama, Nan Ya Plastics Corporation and Far Eastern New Century (FENC) are PET producers in the US.

-German inflation unexpectedly accelerates in February

German consumer prices, harmonized to compare with other European Union countries, rose more than anticipated in February, data showed on Wednesday, pointing to no let-up in stubborn price pressures and pushing up European Central Bank rate hike expectations.

EU-harmonized prices rose by 9.3% compared with the same month a year before, preliminary data from the federal statistics office showed, beating analyst expectations of a rise of 9.0% and slightly higher than January’s 9.2% increase.

Compared to January, prices increased by 1.0%, the office added, also beating forecasts of a 0.7% month-on-month rise. Battery Film – Bio-based thermoplastic

The surprise inflation figures from Europe’s largest economy come a day after two of the euro zone’s biggest economies – Spain and France – also posted unexpected rises.

The ECB has raised interest rates by 300 basis points since July and promised another over-sized move in March, but some policymakers have called for more measured action after March as inflation is now off the highs it hit in October.

Bundesbank President Joachim Nagel pushed back on those calls earlier on Wednesday, saying recent energy price falls may help bring down inflation in the near term, but they do not impact the medium term and price growth was at risk of getting stuck above the ECB’s 2% target. Battery Film – Bio-based thermoplastic

“The interest rate step announced for March will not be the last,” Nagel said in a speech. “Further significant interest rate steps might even be necessary afterwards.”

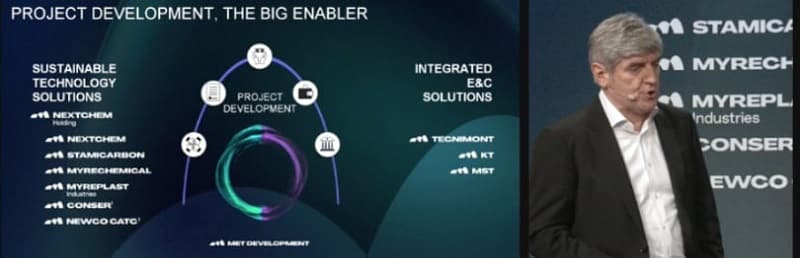

-Maire Tecnimont looks ahead to 2032

The new strategic plan has been presented, with a ten-year horizon. Technologies for bioplastics and recycling in the new Sustainable Technology Solutions division.

The Italian group Maire Tecnimont presented this morning the new far-reaching strategic plan, which targets 2032, a ten-year period – against the usual five-year period – motivated by the time required for engineering technologies to be validated and implemented at an industrial level.

Presenting the plan, the management led by the CEO Alessandro Bernini and the President and founder Fabrizio Di Amato announced the reorganization of the group into two major divisions: Sustainable Technology Solutions (STS), where technologies that are not based on fossil resources will be conferred, such as mechanical, chemical and bioplastics recycling and Integrated E&C Solutions (IE&CS), where executive skills will be concentrated, as general contractor. Battery Film – Bio-based thermoplastic

The first division, STS, will include NexteChem, Myrechemical, Stamicarbon, Myreplast, Conser and the newco CatC, the last two resulting from recent acquisitions; in other words circular economy and energy transition, activities characterized by low volumes – compared to the group’s overall turnover – but for which high margins are expected, accompanied by a low level of risk. Tecnimont, KT and MST will remain in IE&CS. The two segments will be served by a corporate unit dedicated to design and development, MET Development.

In order to create Sustainable Technology Solutions, Maire Tecnimont’s Board of Directors approved the contribution to the newly established NextChem Holding of the entire stake in Stamicarbon and 56.67% of NextChem. Maire Investments, which owns the remainder of NextChem, will subsequently contribute its stake in NextChem Holding. Once some operations have been completed, including a capital increase, Maire Tecnimont will hold 78.37% of NextChem Holding, which in turn will control 100% of both NextChem and Stamicarbon. Battery Film – Bio-based thermoplastic

-DSM Engineering Materials has announced its partnership with sustainability-focused startup DiFOLD, to develop foldable reusable products.

The startup has chosen DSM Engineering Materials’ Arnitel® Eco – a bio-based thermoplastic copolyester – to manufacture its ‘flagship’ Origami foldable water bottle. The company says Adopting Arnitel ECO marks a major step forward in DiFOLD’s mission to reduce the environmental impact of packaging waste.

According to the company the bottle has been inspired by the Japanese art of paper folding, the patented design of DiFOLD’s Origami Bottle means it can fold down to less than 10% of its original volume – DSM claims this greatly improves user convenience and reduces the carbon footprint of shipping. DSM also points to the fact that the Origami Bottle provides a reusable, and recyclable alternative to single-use water bottles – helping to avoid plastic packaging waste. Battery Film – Bio-based thermoplastic

And because the bottles are made from DSM Engineering Materials’ Arnitel Eco, the environmental benefits are even greater.

Arnitel Eco is a bio-based thermoplastic copolyester, partially derived from renewable rapeseed oil. This significantly reduces the material’s cradle-to-gate CO2 emissions – the company claims this helps deliver a carbon footprint reduction of up to 50% compared to traditional copolyesters. This measurement is based on an in-depth life cycle assessment (LCA), which includes every stage of the material’s production, from the growing of the feedstock crops to the finished product that leaves the factory.

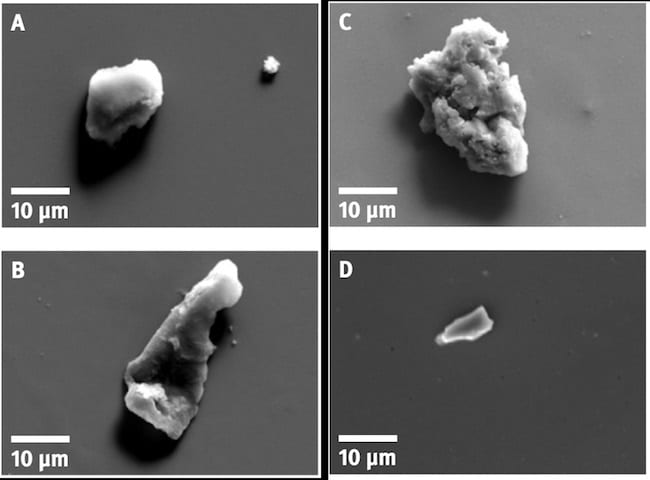

-Tire Wear a Major Source of Microplastics, Say Researchers

Imperial College London experts warn that even though EVs remove the problem of fuel emissions, society will continue to grapple with particulate matter caused by tire wear.

Imperial College London experts are calling for more to be done to limit the potentially harmful impact of toxic tire particles on health and the environment. The researchers from Imperial College London’s Transition to Zero Pollution initiative warn that even though electric vehicles remove the problem of fuel emissions, particulate matter caused by tire wear will continue to be a concern. Battery Film – Bio-based thermoplastic

Six million tonnes of tire wear particles are released globally each year. Particulate matter from tire wear is a significant source of microplastics in rivers and oceans, and tire wear in cities could pose up to a four-fold greater risk to the environment than other microplastics, according to the researchers. Technically speaking, though, it could be argued that identifying thermoset rubber as a type of microplastic could confuse the general public, which tends to associate microplastics with particles derived from discarded items molded from thermoplastic resins that gradually degrade, as well as pellets that escape into the environment before they are molded. The same is true for polyester, nylon, and acrylic lint, which is shed from clothing during each washing cycle and is also a major source of microparticle contamination in waterways.

Despite its prominent presence as a source of microparticulate pollution in the environment, research on the environmental and health impacts of tire wear has been neglected in comparison to fuel emissions.

Imperial College researchers say that the effect of new technologies on the generation and impact of tire wear should be a priority.