Bio-based spandex -FR-Nylon66 28-07-2022 - Arhive

Bio-based spandex -FR-Nylon66

Crude Oil Prices Trend

-Hyosung Creora Now SGS Eco-Certified

Hyosung, the world’s largest spandex manufacturer and the first global developer to commercialize bio-based spandex, has received eco-product certification from Standard Global Services (SGS) guaranteeing that its Creora bio-based spandex is made with plant-based materials and is produced in a harmless and eco-friendly environment.

SGS, an inspection and verification company, is recognized for providing an international standard for quality and reliability. Creora bio-based spandex is produced by replacing 30 percent of petroleum-based resources with bio-based raw materials derived from industrial field corn, which is also called dent corn.

According to a recent third-party life cycle assessment, the manufacture of Creora bio-based spandex reduces its carbon footprint by 23 percent as compared to the production of standard spandex. Bio-based spandex -FR-Nylon66

In addition, the sustainably grown feed-stock used to make the fiber is responsibly grown by farmers who target and measure their efforts to protect the land, air and water.

“Brands are looking to develop deeper connections and trust with consumers concerned with how products they love impact the environment,” said Mike Simko, Hyosung global marketing director for textiles. “As a sustainable textile solution provider, it was very important for us to certify and document Creora bio-based spandex so that our brand partners are able to pass along this verification and sustain consumer loyalty.”

Typically used with other bio-derived natural fibers and bio-derived synthetics, Creora bio-based spandex is suitable for all textile applications used for sportswear, ready-to-wear and loungewear. It provides the same ultra-stretch quality and recovery as Hyosung’s Creora Powerfit spandex, the company noted.

According to Simko, Hyosung is planning to introduce Creora bio-based spandex made with 100 percent bio-derived content.

In addition to Creora spandex, Hyosung manufactures Mipan nylon and specialty polyester. In February, Seoul-based Hyosung said it had invested $37.7 million to expand its Creora elastane plant in Brazil. Bio-based spandex -FR-Nylon66

The project at the company’s industrial park in Araquari increased production capacity by 80 percent to 22,000 tons per year from 12,000 tons.

-High-Tech Textiles Finding Ways Into Automotive Interiors

Ferdinand Dudenhoeffer, a professor at Germany’s University of Duisburg-Essen, notes: “Volvo, Tesla, BMW, Audi and the likes are all turning away from leather seats, reflecting that the circular economy theme is becoming more prominent in their marketing concepts.” Bio-based spandex -FR-Nylon66

The automotive industry always has been a major consumer of textiles, but it is deepening links with specialist fabric companies, including those linked to fashion.

Polestar, the Sweden-based subsidiary of China’s Geely Holding Group, was a key supporting partner of the Global Fashion Summit held in June in Copenhagen, Denmark. The company wants to find new sustainable materials to make a car that leaves the factory gates with a zero-carbon footprint by

While the existing Polestar 2, a 5-door liftback electric vehicle meant to take the Tesla Model 3 head-on, comes with vegan (no leather or animal products in processing) textile seating, the Polestar 5, scheduled for launch in 2024, will have its seat coverings made in an innovative 3D-knitting process that avoids waste.

This system already is used in the fashion and footwear sector, for instance, to make products for major fashion brands such as Uniqlo and Adidas, Polestar says. The Polestar 5 seats’ material mix will include recycled plastic bottles, flax fibers and recycled natural corks from the wine industry. Bio-based spandex -FR-Nylon66

-Partnership between SGT and Avient releases dairy preform with low mineral content

Preform manufacturer SGT has developed, in partnership with colouring specialist Avient, a new single layer dairy preform with a very low mineral content (less than 4%).

Intended for the dairy products market, this 38 mm neck preform incorporates a new additive technology called ColorMatrix Lactra Four One Zero which is claimed to offer superior whiteness to the bottle and high protection for photo-sensitive liquids.

The ColorMatrix Lactra Four One Zero formula allows to block light up to 99.9%, even with a low wall thickness (200 microns). Dairy products, such as UHT milk, sensitive to oxidation are thus protected and kept longer, up to 6 months, without altering taste or sensory and nutritional properties, say the companies.

This 100% recyclable single-layer preform can be integrated into a closed bottle-to-bottle circuit and can contain up to 100% rPET. Bio-based spandex -FR-Nylon66

-Sinopec outbid for Russian ESPO crude in July

China’s Sinopec Corp has cut its purchases of Russia’s ESPO crude oil in July as other buyers, including from India, were willing to pay higher prices, as per Reuters.

A pull-back in Russian oil purchases by Sinopec, Asia’s biggest refiner, suggests that its earlier buying was driven by economics rather than political considerations. Chinese and Indian oil companies have increased their Russian oil imports in May and June despite Western sanctions on Russia as a result of the Ukraine conflict that have upended the global oil trade. Bio-based spandex -FR-Nylon66

China has refrained from condemning Russia’s invasion of Ukraine that started on Feb. 24, which Moscow calls a “special military operation”, and in a meeting on Feb. 4 the leaders of the two countries said their friendship had “no limits”.

Sinopec, through its trading arm Unipec, is expected to lift fewer cargoes in July after submitting lower bids to Russian exporters who then sold the cargos to trading companies and other Chinese clients that bid higher, said four sources who participate in the market and declined to be identified.

Sinopec had been the biggest buyer of ESPO, which loads from the port of Kozmino in Russia’s Far East, in the past two months, snapping up an estimated 20 MM barrels, according to traders and data from tanker tracker Vortexa Analytics.

Sinopec bid at discounts of about USD20 a barrel below the price of Middle East benchmark Dubai on a free-on-board basis for July shipments, similar to what it paying for cargoes in May and June, while deals were done at USD8 to USD13 discounts, the sources said.

“Sinopec may only lift a very small amount as their bids were too low for the Russians,” said one of the four sources, a China-based trading executive. A Sinopec spokesman declined to comment on the company’s purchases.

The companies that beat out Sinopec for the ESPO cargoes in July include Dubai-based trader Coral Energy, state-owned companies CNOOC, PetroChina, and Shandong Port International Trade, which is backed by the local provincial government, according to three trading sources and data from Vortexa. Russia is expected to raise its ESPO exports from Kozmino to a record of 880,000 barrels per day (bpd) in July, Reuters reported on June 7, from an average of 750,000 bpd in 2022. Bio-based spandex -FR-Nylon66

-Is Polystyrene a Sustainable Food Packaging Choice?

Ineos Styrolution America’s sustainability commercial manager, Cassie Bradley, shares the benefits of PS and its future in the circular economy.

Worth $31.6 billion in 2021, the Global Polystyrene Market is projected to reach $44.8 billion by the year 2028, growing at a CAGR of 5.2% over the analysis period of 2022-2028, according to a market study from BlueWeave Consulting.

That’s a whole lot of PS including high-impact polystyrene (HIPS) and expanded PS (EPS).

Although PS containers and packaging are recyclable, recycling rates are not where they should be. According to the EPA’s Advancing Sustainable Materials Management: 2018 Tables and Figures (Table 8, pages 10 and 11), 3.6% of PS containers and packaging are recycled. That figure drops to 0.9% when all municipal solid waste is considered.

What can be done to push that percentage up? Bio-based spandex -FR-Nylon66

That’s where Ineos Styrolution comes into the picture. Cassie Bradley, INEOS Styrolution America’s sustainability commercial manager, explains the company’s strive toward an optimistic future for PS in the circular economy.

The Germany-based company is one of the world’s top two suppliers of styrenics, a precursor to PS. The global company operates 20 production sites in ten countries. Markets include automotive, electronics, household, construction, healthcare, and packaging.

The parent company, Ineos, committed to achieving five ambitious sustainability targets for 2025 that include using an average 30% of recycled content in products destined for PS packaging in Europe and ensuring that 100% of its polymer products can be recycled.

To make that happen Ineos is investing in PS depolymerization plants, collaborating on other advanced recycling schemes, and integrating renewable feedstock in its products.

With that in mind, Cassie Bradley, sustainability commercial manager, Ineos Styrolution, explains why PS is a viable food packaging option in today’s environment in this exclusive Q&A interview.

PS has drawn unwanted attention as a target in the anti-plastics movement including outright bans in some locations. Why is that?

Bradley: Single-use food packaging is an increasingly heated topic, with much of the info reaching the public centered on the undeserved vilification of PS materials. Without accurate facts, solutions are being proposed to implement PS bans which favor unrealistic, one-size-fits-all approaches and promote the use of ineffective alternatives that often have a larger environmental footprint than polystyrene. Bio-based spandex -FR-Nylon66

The realistic solution? Use innovation to create progress within our country’s outdated recycling infrastructure and utilize recycling technologies to keep polystyrene in a circular economy, so that our modern society can continue benefiting from this valuable material while engaging the public on proper plastic waste disposal.

-Halogen-Free & Red-Phosphorus-Free FR Nylon 66 for E&E, Automotive

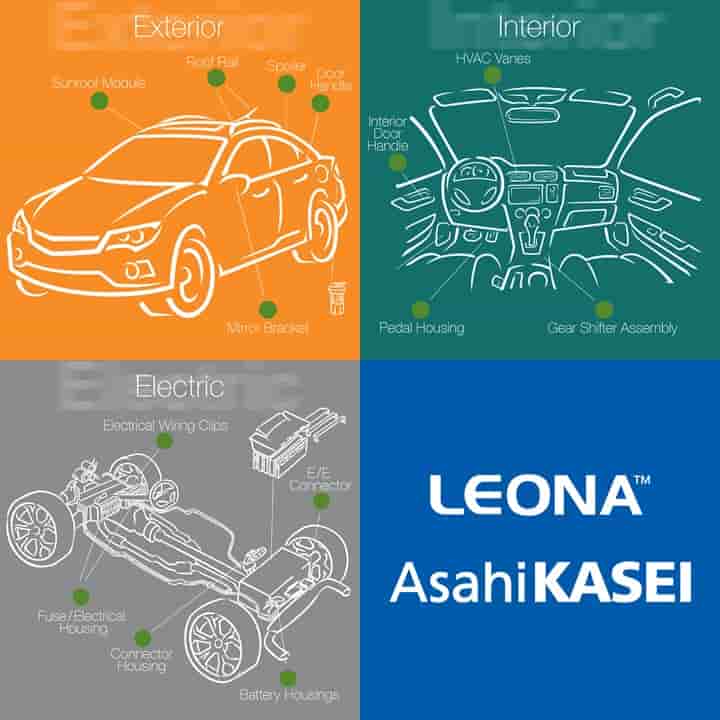

Asahi Kasei’s Leona SN boasts excellent retention of properties, good surface appearance and laser transparency and printability.

A series of halogen-free and red-phosphorus-free flame-retardant (FR) nylon 66 resins now available from Asahi Kasei, are targeted to E&E applications such as breakers, magnet switches, and compressed-air valves as well as automotive applications in powertrain parts and EV charging stations. Bio-based spandex -FR-Nylon66

The new Leona SN series resins boast UL 94 V-0 and relative tracking index (CTI) of 600 V, good surface appearance, good laser transparency (Na) and laser printability (BK). Also claimed are enhanced productivity thanks to clearer and faster laser marking on gloss surfaces, and less mold deposit than conventional halogen-free and red-phosphorus-free materials. Moreover, these resins have been shown to have a higher retention rate of physical properties in a conditioned state. Although the properties of similar halogen-free nylon 66 materials are significantly reduced, Leona SN can still maintain a high level of tensile strength and flexural modulus after moisture absorption. The material can also meet the highest HL3 hazard level requirements for R22 internal components and R23 external components in the European railway fire safety standard EN 45545.

The Leona SN series is part of Asahi Kasei’s Leona nylon resin series. This series of products also includes anti-ultraviolet grades (SU series) and semi-aromatic grades (SG series), which can be used to replace metals and automotive interior applications.

-Ineos Olefins and Polymers Europe joins HolyGrail 2.0

HolyGrail 2.0 is an initiative that uses digital watermarks to improve sorting of end-of-life packaging. Bio-based spandex -FR-Nylon66

Ineos Olefins and Polymers Europe, headquartered in Rolle, Switzerland, has joined HolyGrail 2.0, the digital watermarks initiative designed to improve the sorting and recycling of end-of-life plastic packaging. The company says this move reinforces its commitment to creating a truly circular economy where all plastics can be properly recycled and reused in high-quality products, thereby reducing the carbon footprint of plastic products and packaging.

HolyGrail 2.0 aims to address and improve how postuse plastic packaging is sorted into different types, making recycling more efficient.

The Digital Watermarks Initiative HolyGrail 2.0 uses digital watermarks, or imperceptible codes, that cover the surface of the packaging and are detectable by special cameras linked to high-speed sorting systems.

Ineos says joining the initiative builds on the commercialization of its Recycl-IN range of polyethylene and polypropylene products, which was launched in 2019 to provide converters with a complete portfolio of resins with up to 70 percent postconsumer recycled content and properties on par with virgin polymers.

Rob Ingram, CEO of INEOS Olefins and Polymers North, says, “Partnering with HolyGrail 2.0 demonstrates our commitment to taking action across the value chain to create a more sustainable future. It fits perfectly with the Ineos goal to increase recycling rates and the use of recycled materials back into everyday products. This is an exciting next step on our path to full packaging circularity.” Bio-based spandex -FR-Nylon66

-Advanced Biochemical Thailand (ABT) Launches New EPINITY Brand

Advanced Biochemical Thailand (ABT) has today launched its new product brand, EPINITY™ with a new website. EPINITY™ is the new brand name for ABT’s Epichlorohydrin (ECH), a bio-based, drop-in, and competitive ECH for use in a wide range of downstream industries. Bio-based spandex -FR-Nylon66

Launching EPINITY™ is a key milestone for ABT to represent the company’s long experience in the reliable supply of high quality bio-based ECH and to emphasise its position as a pioneer in supporting its customers and downstream users to achieve their challenging carbon reduction targets to meet Net Zero carbon emission goals.

Mr Masaki Takahashi, Managing Director said, “Building on ten years of ECH production, the new EPINITY™ brand confirms ABT’s position as a leading producer of bio-based ECH and takes us forward into the next decade, a decade which is critical to the future of our planet. EPINITY™ is best-in-class bio-based ECH and I am proud of the ABT team which has worked tirelessly to launch this new brand and website.”

EPINITY™ is mainly used as a precursor to epoxy resins, with uses in protective coatings, electronic components, adhesives and advanced composite materials.

Microplastics – Recycled-plastics 27-07-2022

Bio-based spandex -FR-Nylon66