Bio-plastic-technology – Russia-Ukraine 07-03-2022 - Arhive

Bio-plastic-technology – Russia-Ukraine

The plant will be able to produce a large portfolio of PLA grades serving a broad range of end-use applications from food packaging to kitchen utensils or toys. Replacing traditional plastics with non-fossil based plastics directly contributes to an improved carbon footprint.

The versatility of Sulzer’s PLA technology allows the production of a large range of molecular weights and stereoisomer ratios, while meeting product high-quality standards.

To meet Yangzhou Huitong Biological New Material’s requirements, Sulzer Chemtech will design and provide its lactide purification, polymerization, devolatilization and post-reaction proprietary technologies. The licensing agreement framework also includes extensive service support from engineering to technical assistance and field services. Sulzer Chemtech was selected for its proven track record as market leader, delivering scalable production solutions with both improved efficiency and quality for the production of PLA. Bio-plastic-technology – Russia-Ukraine

Zhang JianGang, President of Yangzhou Huitong Biological New Material, adds: “This new facility will allow us to enter the fast-growing bioplastic market. We consider Sulzer an extremely valuable partner in this project. The company’s comprehensive technical services and cutting-edge production technologies for PLA will help us to effectively produce sustainable plastics and meet our customers’ strategic demands.”

Torsten Wintergerste, Division President of Sulzer Chemtech, comments: “We are excited to support Yangzhou Huitong Biological New Material in their flagship project. Our PLA technologies are currently used in most PLA facilities worldwide.

-Materials firms pulling some business in Russia as Ukraine conflict continues

LyondellBasell Industries will turn down new business opportunities with Russian state-owned entities, and plans to discontinue existing business with those entities as well. Bio-plastic-technology – Russia-Ukraine

Houston-based LyondellBasell also is donating 200,000 euros ($220,000) to relief efforts in Ukraine.

“We are closely monitoring the Russia-Ukraine situation as it continues to evolve,” officials said in a statement sent to Plastics News. “LyondellBasell condemns the unprovoked attacks on Ukraine, and we are taking action to support the humanitarian efforts as a result of this conflict.

“In addition to abiding by all sanctions, effective immediately, LyondellBasell will not enter into any new business transactions or relationships, and to the extent legally possible, intends to discontinue business relationships with Russian state-owned entities. We are in the process of assessing how this will impact our operations, including feedstocks, utilities, supply chain providers, and customers.”

Officials added that although LyondellBasell doesn’t have operations in Ukraine, the firm has seen the rising number of refugees and dislocated families and is supporting the humanitarian crisis through its global corporate citizenship program, Advancing Good. Bio-plastic-technology – Russia-Ukraine

-SK Ecoplant acquires TES Envirocorp

SK Ecoplant will take over TES Envirocorp and enter the global IT equipment and electric vehicle battery recycling and reuse business. As a result, SK Ecoplant has expanded the company’s business to the recycling market that pursues a circular economy.

SK Ecoplant president, Park Kyung-il, and Rodney Muse, managing partner of Navis Capital Partners, the largest shareholder of TES, will hold a 100 percent stake in TES as a result of the acquisition. Bio-plastic-technology – Russia-Ukraine

E-waste refers to discarded electrical and electronic products and is a concept that encompasses all IT devices such as smartphones, laptops, servers and storage devices, waste batteries, waste home appliances, and waste solar power parts that have reached the end of their lifespan.

Currently, TES has 43 treatment facilities in operation in 21 countries, including countries in North America and Europe. The U.S., U.K., Germany, China, and Singapore are major core markets.

SK Ecoplant plans to achieve a circular economy with zero waste of resources and global pollution through recycling and energy conversion of waste. According to the 2020 Global E-waste Monitor report by the United Nations (UN), the amount of e-waste generated worldwide in 2019 was about 53.6 million tons, and it is expected to increase to 74.7 million tons in 2030. Allied Market Research, a global market research firm, predicts that the size of the e-waste industry from about $50 billion (about 60 trillion won) in 2020 will nearly triple to about $144 billion (about 170 trillion won) by 2028. there is. Bio-plastic-technology – Russia-Ukraine

-Teijin Expands Carbon-Fiber Thermoplastic Lineup

The company’s move to offer commodity engineering plastic prepregs will boost appeal to automakers.

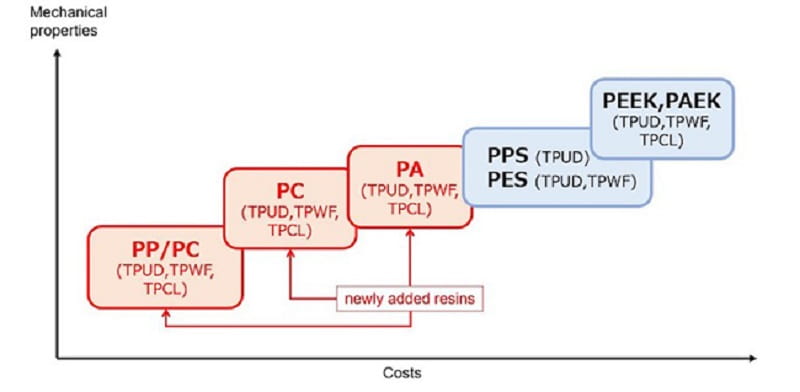

Until recently, Japan’s Teijin has offered high-performance carbon-fiber prepegs using advanced engineering plastics such as polyetheretherketone (PEEK), polyaryletherketone (PAEK), and polyethersulfone (PSE), as well as polyphenylene sulfide (PPS). Bio-plastic-technology – Russia-Ukraine

To further its aspirations to expand carbon-fiber composite usage in the auto sector, Teijin is now offering three additional matrix materials: Polypropylene (PP)/polycarbonate (PC), PC, and polyamide (PA).

These are now being used as base resins in new versions of the company’s existing prepreg products, including Tenax ThermoPlastic UniDirectional (TPUD), Tenax ThermoPlastic Woven Fabric (TPWF), and Tenax ThermoPlastic Consolidated Laminate (TPCL). Bio-plastic-technology – Russia-Ukraine

-Foam Cycle’s styrofoam recycling technology receives U.S. patent

Foam Cycle, a foam packaging recycling system designed to be placed at outdoor municipal recycling drop-off centers, was recently issued a Utility Patent by the United States Patent and Trademark Office. The patent outlines a “method and system of recycling polystyrene waste.” Bio-plastic-technology – Russia-Ukraine

Foam packaging, also known as styrofoam, is one of the most plentiful, yet least recycled plastics used today. With packaging waste shifting from retailers to direct home delivery, foam packaging waste is too large to be placed in curbside containers and is not accepted by most single-stream recycling facilities. Foam packaging waste joins a long list of other hard-to-recycle materials that cannot be collected at the curb, such as mattresses, tires, rigid plastics, metals, and electronics. When dropped off at a recycling collection center equipped with a Foam Cycle system, foam packaging is able to be recycled.

The Foam Cycle system is designed as an encapsulated “plug and play” system to collect, recycle and repurpose foam packaging waste.

When foam packaging waste is processed through the Foam Cycle system, 98 percent of the air is safely released and 2 percent of the polystyrene plastic is extruded, resulting in a 90-1 densification. Bio-plastic-technology – Russia-Ukraine

-World’s first Lyocell T-Shirt from 100% recycled textiles

Due to the superior cellulose properties of cotton in the recycled textiles, the fiber tenacities are even superior compared to wood based Lyocell fibers

At the International Conference on Cellulose Fibers 2022 at 02/03. Feb in Cologne, LIST Technology AG from Switzerland presented world’s first Lyocell T-Shirt from 100% pulp from recycled textiles – made possible by the use of LIST KneaderReactor technology. Bio-plastic-technology – Russia-Ukraine

The recycled textiles came from post-consumer sources. The T-Shirt is fully recyclable. The fiber tenacities are even superior compared to wood based Lyocell fibers. This is due to the superior cellulose properties of cotton in the recycled textiles, which generates pulp which still can be processed at 100% due to LIST’s high viscosities capabilities. The recyclability refers to textiles from cotton or polycotton, but also to textiles from Lyocell fibers from recycled textiles.

Bio-plastic-technology – Russia-Ukraine