Biobased acrylonitrile Plastic Recycling 14-01-2022 - Arhive

Biobased acrylonitrile Plastic Recycling

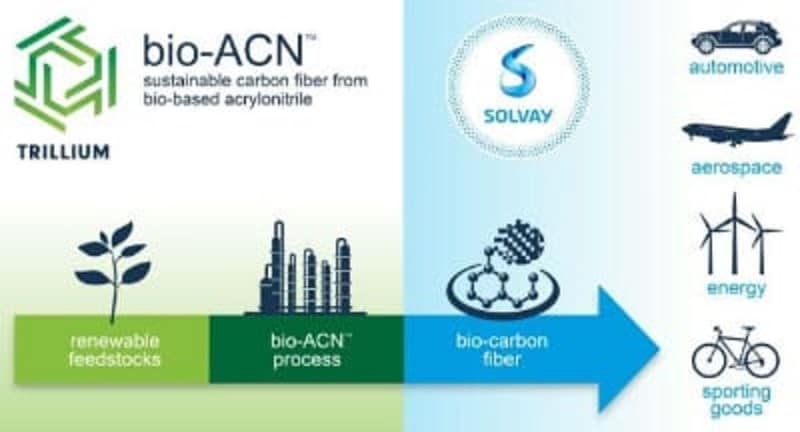

-Solvay to collaborate with Trillium on bio-based acrylonitrile for carbon fiber applications

New agreement with Trillium Renewable Chemicals will enable Solvay’s development of sustainable, bio-carbon fiber for use in various applications.

Solvay and Trillium Renewable Chemicals have signed a letter of intent to develop the supply chain for bio-based acrylonitrile (bio-ACN). Trillium will supply Solvay with bio-ACN from Trillium’s planned commercial asset, and Solvay will evaluate bio-ACN for carbon fiber manufacturing as part of its long-term commitment to developing sustainable solutions from bio-based or recycled sources. The aim of this partnership is to produce carbon fiber for use in various applications such as aerospace, automotive, energy, and consumer goods.

Acrylonitrile is a chemical intermediate typically made from petroleum-based feedstocks like propylene and is the primary raw material used in the production of carbon fiber. Biobased acrylonitrile Plastic Recycling

Trillium’s Bio-ACNTM process delivers acrylonitrile from plant-based feedstocks like glycerol with a lower carbon footprint.

“We are thrilled to be partnering with Trillium which aligns well with our Solvay One Planet commitment to more than double our revenue based on renewable or recycled materials by 2030,” comments Stephen Heinz, head of composite research & innovation, Solvay.

Innovation partnerships such as this are driven by a desire to make a real-world sustainability impact. Bio-based feedstocks are a key part of Solvay’s sustainability strategy, and we look forward to being a consumer of bio-ACN from Trillium’s first bio-based acrylonitrile plant. Biobased acrylonitrile Plastic Recycling

Stephen Heinz, head of composite research & innovation, Solvay-

-Is Plastic Recycling Just a Big Fraud?

This article was previously published March 18, 2020, and has been updated with new information.

As plastic pollution has become a more well-recognized problem, public awareness about the need for recycling has grown as well.

The question is whether or not recycling is a viable answer. Growing evidence suggests plastic recycling efforts can have only a minor impact even under the best of circumstances. Biobased acrylonitrile Plastic Recycling

“Consumers are led to believe that the Earth would be healthy, if only they recycled properly, when, in reality, there is no market for most plastics to be recycled …

Past studies have shown only about 10% of plastic gets recycled, but … once those numbers are updated to reflect the recent collapse of the recycling market, it will probably show that only about 5% is getting recycled.”

Increasing recycling may sound like the answer, but as Jim Puckett, executive director of the Basel Action Network, tells Tim Dickinson of Rolling Stone magazine,2 “When you drill down into plastics recycling, you realize it’s a myth.”

“Since 1950, the world has created 6.3 trillion kilograms of plastic waste — and 91 percent has never been recycled even once, according to a landmark 2017 study published in the journal Science Advances.

Unlike aluminum, which can be recycled again and again, plastic degrades in reprocessing, and is almost never recycled more than once,” Dickinson writes.3

“Modern technology has hardly improved things: Of the 78 billion kilograms of plastic packaging materials produced in 2013, only 14 percent were even collected for recycling, and just 2 percent were effectively recycled to compete with virgin plastic. ‘Recycling delays, rather than avoids, final disposal,’ the Science authors write. And most plastics persist for centuries.”

Companies Sued for Creating Plastic Pollution

As reported by The Guardian,4 Earth Island Institute filed a lawsuit5,6 against 10 major companies at the end of February 2020, in an effort to force them to take responsibility and pay for the environmental and ecological destruction their products are causing. Biobased acrylonitrile Plastic Recycling

According to Environmental Health News,7 “Two-thirds of all plastic ever produced remains in the environment,” which helps explain why tap water, bottled water,8 sea salt9 and a variety of seafood10 all come with a “side order” of microplastic.

At the rate we’re going, plastic will outweigh fish in our oceans by 2050.11,12 By 2009, plastics already outweighed marine plankton 6-to-1,13 and more than half of the plastic currently inundating every corner of the globe was created in the last 18 years alone.14 With plastic pollution estimated to double in the next decade,15 it’s quite clear we’re traveling full speed ahead on an unsustainable path.

The companies named in the suit — Coca-Cola, Pepsi, Nestlé, Clorox, Crystal Geyser, Mars, Danone, Mondelēz International, Colgate-Palmolive and Procter & Gamble — were identified as the top producers of the plastic debris collected during a worldwide audit in 2019, in which 72,000 Break Free From Plastic volunteers picked up beach trash.

Novelis Inc. has announced it will invest $365 million to build a highly advanced recycling centre for automotive in North America. With an annual casting capacity of 240 kt of sheet ingot, the facility is expected to reduce the company’s carbon emissions by more than one million tons each year. The new recycling facility will be built adjacent to Novelis’ existing automotive finishing plant in Guthrie, Kentucky.

The centre will enable Novelis to grow its closed-loop-recycling programs with more automotive customers in North America. Through closed-loop recycling, the company takes back the aluminium remaining after automotive parts are stamped from sheets and remakes it into the same product for new vehicle production. The centre will also have the capability to process aluminium from vehicles at the end of their lifecycle. Using recycled aluminium as input material requires only 5% of the energy used to make primary aluminium, thus avoiding 95% of the carbon emissions associated with production. Biobased acrylonitrile Plastic Recycling

“Novelis aims to be the world’s leading provider of low-carbon, sustainable aluminium solutions that advance our business, industry and society toward the benefits of a circular economy,” said Steve Fisher, President and CEO of Novelis, Inc. “Through this investment, we will continue to increase the amount of recycled content in our products, reducing our CO2 emissions and moving us closer to carbon neutrality.”

The new recycling centre will be equipped with industry-leading processes and capabilities, including advanced shredding and sorting technology, as well as energy-efficient innovations to support the company’s sustainability goal to reduce energy intensity by 10 % by 2026. Ground-breaking is scheduled for early 2022, with commissioning expected in 2024. Biobased acrylonitrile Plastic Recycling

When fully operational, the expansion will add approximately 140 new jobs in Guthrie. This announcement is on the heels of Novelis’ October grand opening of the automotive finishing plant in Guthrie, which currently employs 150 people and will grow to 190 over the next two years.

-Gabriel-Chemie launches new product range named MaxiBlue and MaxiLoop

Since 1970, Gabriel-Chemie has been producing its well-known high quality masterbatch under the brand name „Maxithen“. These mainly include products, that are based on fossile polyoefines as carrier polymers. The company is now introducing its new product range as an addition to the „Maxithen“.

The new product line MaxiBlue consists mainly of renewable or biogenic polymers or those of chemical recycling. This also includes plant based colour additives (natural colours). Biobased acrylonitrile Plastic Recycling

The new product line MaxiLoop is all about recycling and the circular ecomony. Included are products based on regenerated material as well as products, which support the circular economy.

„With these new product lines, we respond to the wishes of our customers and brand manufacturers, who are paying more and more focus on their CO2 footprint of their products and packaging. With MaxiBlue and MaxiLoop, we offer numerous, serious alternatives without having to compromise on functionality and look and feel“, mentions Stefanie Sommer, Chief Strategy & Sustainability Officer.

The introduction of the new product range underlines and extends Gabriel-Chemie’s sustainabiliyy strategy even further and offers customers a climate-friendly alternative to fossile products. Biobased acrylonitrile Plastic Recycling

-US inflation rate highest since 1982

US inflation rose by 7pc in December, the fastest annual rate since 1982, as surging consumer demand outpaced overburdened supply chains.

The consumer price index topped the previous month’s annualized 6.8pc rate, the Bureau of Labor Statistics said. Prices rose from the prior month by 0.5pc in December on a seasonally adjusted basis, easing from a 0.8pc gain in November.

Prices excluding food and energy — so called core inflation — rose by 5.5pc from a year earlier, the biggest increase since 1991. The energy index rose by 29pc and the food index rose by 6.3pc. Biobased acrylonitrile Plastic Recycling

The Federal Reserve has signaled three possible hikes to its benchmark interest rate beginning as early as March, after it completely winds down its enhanced bond buying program. Asset manager Emles Advisors said today’s report had “little chance of derailing” the Fed’s likely course.

On a month-over-month basis, the energy index fell by 0.4pc in December, the first drop since April, as indexes for gasoline and natural gas both declined. The energy index had risen by 3.5pc in November following a monthly gain of 4.8pc in October.

Core inflation rose by 0.6pc on the month, following a 0.5pc gain in November.

-Europe’s PVC Industry Fights Back Against NGO Misinformation

PVCMed Alliance urges policymakers and healthcare establishments to reject conclusions of error-prone paper.

The medical PVC industry is warning European policymakers and hospitals that a paper published in 2021 by an influential non-governmental organization (NGO) that encourages phasing out the use of PVCs is rife with misinformation and should not be used as a source for crafting policy. Biobased acrylonitrile Plastic Recycling

PVCMed Alliance, aligned with the European Council of Vinyl Manufacturers to raise awareness and promote informed decisions about the use of PVC in healthcare, said the NGO published a paper falsely stating that PVC cannot be recycled; that it is easily replaced by other materials; and that it contains chemicals that are detrimental to human health and the environment.

“The paper contains so many errors that we must urge European policymakers and hospitals to disregard it,” said Ole Grøndahl Hansen, PVCMed Alliance Project Manager. “Many hospitals around Europe are currently investigating how to implement circular initiatives for their plastic waste. Paradoxically, if they decide to follow the recommendations from NGOs, hospitals will do more harm than good for the environment.” Biobased acrylonitrile Plastic Recycling

PVCMed Alliance has released a 24-page document, “Why PVC Should Remain the Preferred Material in Healthcare and Elsewhere.” Some of its key points include:

PVC is the most-used plastic for medical devices in Europe with a market share of approximately 30%. PVC is safe to use, versatile, recyclable, and economical.

Biobased acrylonitrile Plastic Recycling