Biobased polymers polylactic acid - Arhive

Bio-based polymers capacity, market to grow 4pc

The capacities and production of bio-based polymers will grow at a compound annual growth rate (CGAR) of about 4 per cent until 2023, a report said.

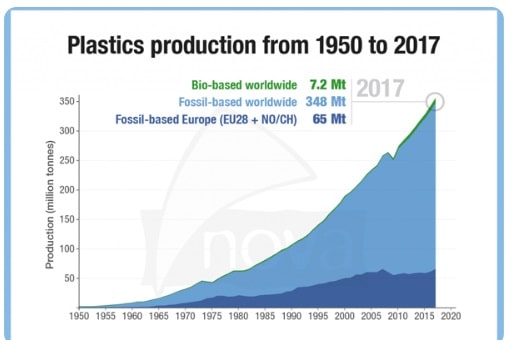

This will be at about the same rate of growth of petrochemical polymers and plastics, said the “Bio-based Building Blocks and Polymers – Global Capacities, Production and Trends 2018-2023” report from the German nova-Institute.

The total production volume of all bio-based polymers reached 7.5 million tonnes in 2018, about 2% of the production volume of petrochemical polymers, a report said.

The potential of bio-based polymers is much higher, but is currently hampered by low oil prices and a lack of political support, said Biobased polymers polylactic acid

The production of bio-based polymers has become much more professional and differentiated in recent years. By now, there is a bio-based alternative for practically every application, it said.

The increase in production capacity is mainly based on the expansion of the polylactic acid (PLA) production in Thailand and the polytrimethylene terephthalate (PTT) and starch blends production expansion in US. Biobased polymers polylactic acid

Especially PLA and starch blends will continue to grow significantly until 2023. Also new capacities of bio-based polyamides, polyethylene (PE) and, for the first time, polypropylene (PP) and poly(butylene adipate-co-terephthalate) (PBAT) will also be added in Europe in this period.Biobased polymers polylactic acid

The great hopeful polyethylene furanoate (PEF) will presumably only be able to offer commercial capacities after 2023.

Overall, the market environment remains challenging with low crude oil prices and little political support, the report said.

So far, the two major advantages of bio-based polymers have not been politically rewarded.

The first advantage is that bio-based polymers replace fossil carbon in the production process with renewable carbon from biomass.

This is indispensable for a sustainable, climate-friendly plastics industry and is not yet politically rewarded, the report said.

The second advantage is offered by about a quarter of bio-based polymer production: They are biodegradable (depending on the environment) and can therefore be a solution for plastics that cannot be collected and enter the environment where they can biodegrade without leaving behind microplastics. Only a few countries such as Italy, France and, in future probably Spain will politically support this additional disposal path, the report said.