Biodegradability Hydrogen Ethanol Plastic 29-10-2021 - Arhive

Biodegradability Hydrogen Ethanol Plastic

Crude Oil Prices Trend

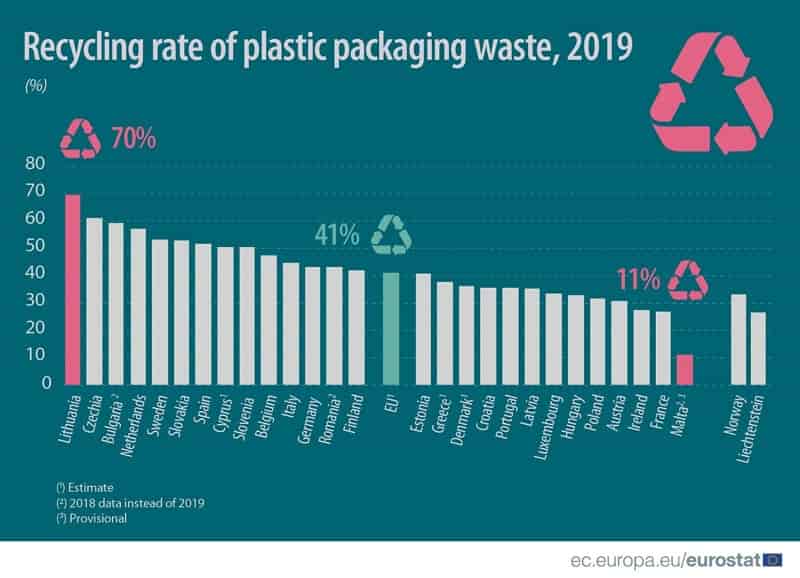

-EU recycled 41% of plastic packaging waste in 2019

In 2019, each person living in the EU generated 34.4 kg of plastic packaging waste, out of which 14.1 kg was recycled.

This information comes from data on packaging waste published by Eurostat today.

Between 2009 and 2019, the volume of plastic packaging waste generated per inhabitant increased by 24% (+6.7 kg). The recycling volume of plastic packaging waste increased sharply over the same period, by 50% (+4.7 kg). Despite this improvement, the amount of plastic packaging that wasn’t recycled increased by 2.0 kg per inhabitant since 2009 due to the greater increase in the absolute value of plastic packaging waste generated.

In 2019, an estimated 41% of plastic packaging waste was recycled in the EU. Nine EU Member States recycled more than half of the plastic packaging waste generated: Lithuania (70%), Czechia (61%), Bulgaria (59%, 2018 data), the Netherlands (57%), Sweden and Slovakia (both 53%), Spain (52%), Cyprus (51%) and Slovenia (50%).

In contrast, less than one-third of plastic packaging waste was recycled in Malta (11%, 2018 data), France (27%), Ireland (28%), Austria (31%), Poland (32%) and Hungary (33%).

-Plastics have smaller environmental impact than alternatives, according to industry association

The Plastics Industry Association (PLASTICS) has published a report that analyzes scientific data on the environmental impacts of plastics and finds plastics to be more sustainable than alternative materials when life cycle assessments are taken into consideration. The report, authored by environmental scientist Kenneth Green and titled Plastics and Sustainability, further finds that eliminating plastics would be detrimental to ongoing sustainability efforts and that enhancing recycling systems is a practical solution.

“Too often we see groups criticize plastics using unscientific information. The report released today summarizes what data has indicated for years: plastic is lighter and more durable than alternatives, and it has a smaller environmental footprint,” said Tony Radoszewski, President & CEO of PLASTICS. “Switching to alternatives would not only harm an industry that employs almost a million Americans, but it would also harm our environment and our well-being.” Biodegradability Hydrogen Ethanol Plastic

Plastics and Sustainability examined numerous life cycle assessments to determine differences in methodologies measuring the sustainability of different materials, including steel, aluminum, glass, and others. The report acknowledges that plastics’ sustainability can and should continue to improve over time.

“Assessing sustainability has to include plastic’s impacts on the physical environment as well as the climate, including the production of plastics from fossil fuels, and disposal of plastic waste into the environment. But we must take care in choosing alternatives,” said author Kenneth Green. “Comparison studies and common sense tell us that alternative materials will also produce environmental impacts, quite possibly worse than the plastics they replace.”

-Lenzing AG / World-renowned marine research institute confirms biodegradability of LENZINGT fibers

Results of experiments conducted by the Scripps Institution of Oceanography provide further proof that LENZINGT fibers offer an effective substitute to

synthetic fibers. Lenzing/San Diego – The Lenzing Group, a world-leading provider of wood-based specialty fibers, has received further scientific proof of the biodegradability of its fibers. In a study published in October 2021[1], scientists from the prestigious academic research institute Scripps Institution of Oceanography (SIO) at the University of California, San Diego confirmed that wood-based cellulosic fibers biodegrade in the ocean within a short period of time at the end of their life cycle, making them a better alternative to fossil-based fibers.

The research was the result of an independent project trying to understand the “end-of-life” scenarios for textiles and nonwovens discarded in the environment.

SIO has a global reputation for being one of the oldest, largest and most important marine research centers worldwide. In this study, SIO compared the degradation processes of nonwovens made from fossil-based synthetic materials such as polyester with those of cellulosic materials such as Lenzing’s wood-based lyocell, modal and viscose fibers in specific scenarios – under various real oceanic conditions and controlled aquaria conditions. The results of these experiments are striking: while wood-based cellulosic fibers fully biodegraded within 30 days, the fossil-based fibers tested were practically unchanged after more than 200 days.

-Essity invests in green hydrogen tissue production pilot

Essity is set to launch a pilot project at its facility in Mainz-Kostheim, Germany, which will involve replacing natural gas with green hydrogen to enable allegedly CO2-free tissue production.

The Mainz-Kostheim site will test the extent to which green hydrogen represents a viable alternative to natural gas without compromising product quality in the tissue production process. This will involve an initial installation period and re-build of the facility’s paper machines. Biodegradability Hydrogen Ethanol Plastic

Following this, Essity says it intends to gradually add green hydrogen to its energy supply. The company has set the target of running the drying hood of the paper machine on 100% green hydrogen by autumn 2022.

So-called green hydrogen uses renewable energy to power the electrolysis of water and is viewed by some as an important solution for achieving carbon neutrality across various industries as its only by-product is oxygen. It is an alternative to grey hydrogen, which is produced using fossil fuels and can release greenhouses gases back into the atmosphere, and blue hydrogen, which captures and stores emissions, although there are still some challenges involved in scaling green hydrogen.

Essity’s initial investment in the pilot is approximately €4 million.

Magnus Groth, president and CEO of Essity, comments: “We will be the first in the world to use green hydrogen for tissue production.

-Novozymes launches new high-performance yeast for ethanol industry: Innova Quantum

Novozymes is introducing Innova Quantum, a new addition to its Innova yeast platform. The robust new yeast enables ethanol plants with longer fermentation times of more than 60 hours to realize higher ethanol yields and processing efficiencies than ever before. Most importantly, plants can achieve this industry-leading yield without trade-offs which put their operation at risk, Novozymes said.

Innova Quantum has significant robustness and works particularly well under differing processing conditions. This means that ethanol producers can maintain consistency in challenging conditions, maximize the fermentation process towards optimal starch conversion, and achieve the highest ethanol yields in the industry, Novozymes said.

Using a yeast bred to thrive through temperature excursions up to 98°F (37 °C), operators diminish downtime, increase plant efficiency and output in any season, and improve production. With Quantum’s exceptional lactic and acetic acid tolerance, plants can reduce the risk of slowing down or shut down due to fermenter loss, enabling plants and operational teams to power through infection events more easily.

Producers can increase ethanol yield by 2-3% with the new yeast, which for a 100MGY plant translates to an additional $1-2 million in revenue. Designed to operate in fermentations of more than 60 hours, Quantum with new strain development is capable of converting the most sugar to ethanol while significantly lowering fermentation by-products such as glycerol up to 40%—all without the trade-off and risk of robustness loss experienced with competing yeasts.

Quantum expands plant flexibility fermenting to more than 16% w/v ethanol concentrations, while eliminating the need for expensive nutritional supplements.

Within three years of Innova yeasts emergence on the market, nearly half of North American ethanol is produced using Innova yeasts, indicating how the platform fulfils a significant market need for groundbreaking bioinnovation that makes a real, tangible difference for producers.

-Notpla is a biodegradable material designed “to make packaging disappear”

Sustainable startup Notpla has created an edible, biodegradable packaging made from seaweed and plants that was designed to replace plastic.

Notpla‘s eponymous packaging has been shortlisted for this year’s Dezeen Awards in the sustainable design category. Biodegradability Hydrogen Ethanol Plastic

Its name is a shortening of “not plastic,” referring to the fact that while it looks plastic, the product is actually made from seaweed and plants.

Branding agency Superunion coined Notpla’s name name as well as a visual identity for the startup. This includes an animated logo that resembles a vessel filling up with water that is only visible when “filled” – as is the case with clear packaging.

“Notpla is a seaweed-based, sustainable packaging startup on a mission to make packaging as we know it disappear naturally,” Superunion senior creative director Mark Wood told Dezeen.

“Every year, 8 million tonnes of plastic are dumped in the oceans. The world’s behaviours need to change when it comes to single-use plastic,” he explained.

-Next-Generation Graphite for Thermoplastic and Composites Applications

NeoGraf’s new Graf-X graphene nanoplatelets (GNP) and graphene precursos (GP) extend the company’s range of next-generation graphite materials.

Two high-performance additives extend the range of next-generation graphite materials from developer and manufacturer of high-performance natural and synthetic graphite sheet and powder products NeoGraf Solutions. Both new Graf-X graphene nanoplatelets (GNP) and graphene precursors (GP) reportedly enhance mechanical strength, electrical conductivity, and thermal properties of thermosets and thermoplastics such as PP, nylons, HDPE, LDPE, LLDPE, EPS and XPS, PVC, and PET. These advanced additives can be used in a range of plastic applications including electrically conductive fillers for electrostatic discharge (ESD) plastics in automotive and aerospace electronics and heat resistance additives for underhood plastic components such as HVAC systems, water pump housings, and valve covers.

-DyStar to exhibit at China Interdye 2021 in Shanghai

DyStar, a leading specialty chemical company, is exhibiting at the 21st China Interdye 2021 from November 17-19 at the National Exhibition and Convention Centre, Shanghai. The largest global exhibition for the dye-chem industry will consist of technical seminars, conferences and events organised by exhibitors and relevant industry associations, respectively.

DyStar’s managers at Booth 3C011 in Hall 6.2 will discuss various sustainable solutions which we offer to the textile supply chain. “We will also be showcasing our latest product innovations for visitors from brands and retailers, manufacturers, and production houses to enhance their manufacturing process and improve end-product quality,” DyStar said in a press release. Biodegradability Hydrogen Ethanol Plastic

As the supply chain continues to be challenged by the global pandemic, manufacturers and producers around the world are constantly looking for essential sustainable solutions to help them on their journey of production. DyStar is determined to support the global chemical industry and its customers with invaluable insights and experience from our legacy of innovations.

-Plastic Omnium cuts costs as chip crunch hits sales

Supplier is sharpening focus on cost reduction and cash generation

Plastic Omnium reported on Wednesday a drop of more than 14 percent in its third-quarter sales as the supplier reduces costs to blunt the blow of customers’ cuts in output over component shortages.

The chip shortage has seen major automakers worldwide — still recovering from coronavirus disruptions — cut or even suspend their production, eating into demand for auto parts.

The French supplier which makes fuel systems, bumpers and tailgates for cars, reported sales of 1.79 billion euros ($2.08 billion), down from 2.10 billion a year ago.

“We are significantly sharpening our focus on cost reduction and cash generation,” CEO Laurent Favre said in a statement, citing an “exceptionally volatile market” due to the ongoing shortages in semiconductor chips.

Biodegradability Hydrogen Ethanol Plastic