Biodegradable Polymer rPET Material 22-09-2021 - Arhive

Biodegradable Polymer rPET Material

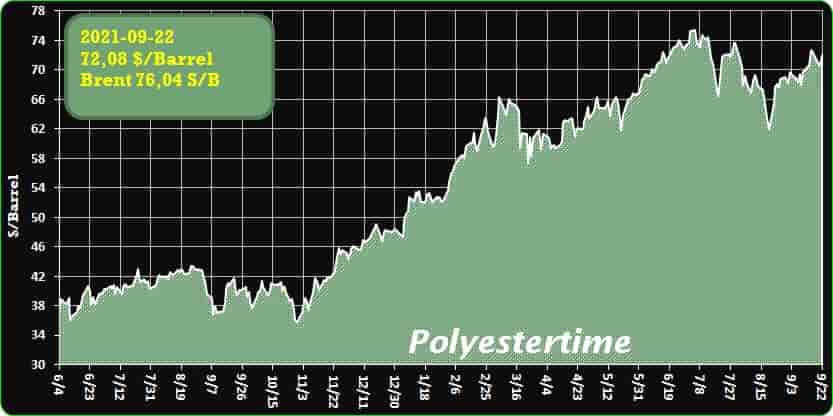

Crude Oil Prices Trend

-The biodegradable polymer PBAT is hitting the big time

Polybutylene adipate co-terephthalate is succeeding by straddling the peterochemical and biopolymer worlds

The perfect polymer—one that balances physical properties and environmental performance—doesn’t exist, but polybutylene adipate co-terephthalate (PBAT) comes closer than many.

Producers of synthetic polymers have for decades failed to stop their products from ending up in landfills and oceans, and they are now under pressure to take responsibility. Many are redoubling efforts to boost recycling to fend off critics. Other firms are trying to tackle the waste problem by investing in biodegradable biobased plastics such as polylactic acid (PLA) and polyhydroxyalkanoate (PHA), hoping natural degradation will mitigate at least some of the waste.

But both recycling and biopolymers face obstacles. Despite years of effort, the plastics recycling rate in the US, for instance, is still less than 10%. And biopolymers—often the products of fermentation—struggle to achieve the same performance and manufacturing scale of the established synthetic polymers they are meant to replace.

-Starlinger Producing New White rPET Material

Trays, cups, and food containers manufactured from the white rPET are alternatives to single-use cups made from materials like polypropylene (PP) or polystyrene (PS).

Starlinger viscotec, a division of the Austrian machinery supplier Starlinger & Co GmbH, has developed a new material to make packaging for dairy and hot-fill products fully recyclable. rPET100 is said to combine the environmental advantages of recycled PET with easy material processability.

Food packaging for applications like dairy, hot drinks, instant soups, and ready-meals must withstand higher temperatures during the production process.

Additionally, dairy products require packaging with optimal light and gas barrier for longer shelf life. The new rPET100 sheet combines these benefits and adds new ones: it is heat resistant, made from mono-material, and its white color protects the product from UV light. Once used, the packaging can be 100% recycled because it contains no other polymer additives. Biodegradable Polymer rPET Material

-Evian unveils 100% rPET bottles created by Loop Industries’ innovative recycling technology

This Recycle Week, Evian has launched a new recycled plastic (rPET, or recycled polyethylene terephthalate) prototype bottle using revolutionary technology from clean technology company Loop Industries.

This marks a significant milestone in Evian’s 2025 circularity journey, which will see it accelerate the transition to 100% recycled plastic (excluding the cap and label) in all of its plastic bottles. Biodegradable Polymer rPET Material

Committed to accelerating the development of innovative sustainable packaging solutions, Evian achieves a new milestone in circularity journey with launch of prototype bottle using revolutionary technology from Loop Industries that allows no and low value plastics (that otherwise go to waste) to be recycled endlessly into new, virgin quality plastic.

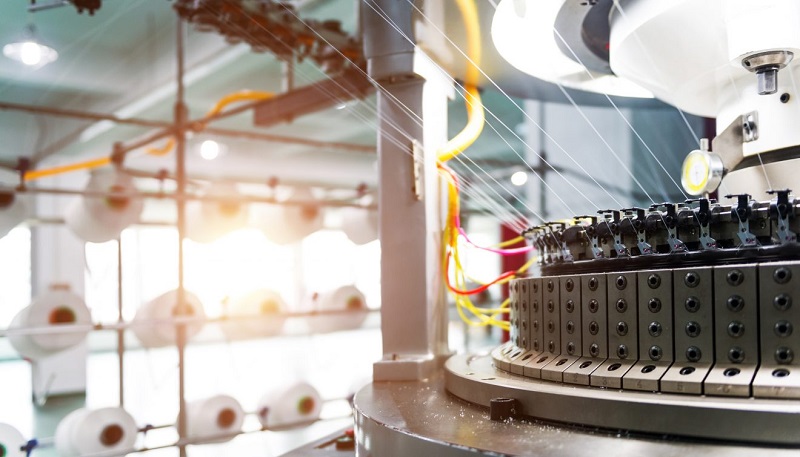

In collaboration with other textile industry operators, VTT and Finnish Textile & Fashion have prepared a roadmap for the Finnish textile and fashion industry extending up to 2035 Biodegradable Polymer rPET Material

The textile industry is undergoing a major transformation globally. New ecological textile fibres are entering the market and digitalisation is boosting the global reorganisation of production. Finland can seize the opportunities created by the transformation and win investments amounting to more than billion euros. The textile cluster wants to create the world’s most responsible and functional textile cycle and production in Finland. In collaboration with other textile industry operators, VTT and Finnish Textile & Fashion have prepared a roadmap for the Finnish textile and fashion industry extending up to 2035.

The ongoing industrial transformation will enable the creation of new business and jobs in Finland. Finland’s strengths in production are related to sustainable raw material base, know-how and innovation platforms. In the fields of bio-based raw materials and smart technologies, Finland is one of the world’s leading countries in terms of expertise.

“For Finland, the reorganised textile industry would mean an estimated EUR 1.2 billion in investments, some 17,000 new jobs and a global reputation boost as a leading country in sustainable development,” says Research Professor Ali Harlin from VTT.

-Largest sorting plant in Latin America is up and running in Mexico City

The Azcapotzalco Transfer Station and Sorting Plant, the largest and most modern in Latin America, has opened its doors in Mexico City (CDMX). With this facility, the city government is the first in the country to move towards establishing effective, proper treatment of urban waste based on a circular economy concept – one of the priority objectives of the current administration. Biodegradable Polymer rPET Material

The new Azcapotzalco facility is the country’s first government-owned automated plant for the separation and treatment of municipal solid waste. The 11,000 m2 facility sorts paper, cardboard, multilayer packaging, PET and HDPE, plastic bags and film, aluminum cans, metallized bags, textiles, glass and other metals. The plant was commissioned in May 2021. It operates in conjunction with a transfer station to process around 1,000 tons per day of waste from the municipalities of Cuauhtémoc, Gustavo A. Madero, Miguel Hidalgo and Azcapotzalco, and will be able to receive up to 1,400 tonnes of waste per day. Its operation will generate 404 jobs.

-Milliken colorant, additive and sustainability solutions on full display at Fakuma 2021

Ghent, Belgium – Milliken & Company, a globally recognized leader in polymer additives and colorants, offers many ways to improve your resin formulations, compounds, end products and sustainability. As an exhibitor in Booth B2-2105 at Fakuma 2021, Milliken will be showcasing its portfolio, and offering access to the vast technical knowledge of its various experts.Biodegradable Polymer rPET Material

At the show — taking place Oct. 12-16 in Friedrichshafen, Germany — learn more from Milliken about the following products:

- Millad® NX® 8000 ECO clarifier for polypropylene (PP);

- KeyPlast® and KeyPlast RESIST™ colorants for plastics;

- Hyperform® HPN® high-performance additives for PP, polypropylene homopolymers and impact copolymers (ICP); and

- DeltaMax® performance modifiers for PP used by converters processing impact copolymers or recycled polypropylene (rPP) resins.

-SARS-CoV-2, Influenza A inactivated by zinc-embedded nylon fabric

A paper published in ACS Applied Materials Interfaces details effectiveness, describes protocol for future testing

An international team of scientists and engineers from the University of Cambridge, the Icahn School of Medicine at Mount Sinai, ResInnova Labs and Ascend Performance Materials has found that a nylon fabric embedded with zinc ions successfully inactivated 99% of the viruses that cause COVID-19 and the common flu. Biodegradable Polymer rPET Material

Face masks, protective clothing and filters are used to slow the spread of viruses. But poor-quality masks can harbor active viruses from infected wearers, posing a transmission risk.

“A major challenge is absorption and inactivation,” said Vikram Gopal, Ph.D., co-senior author and chief technology officer at Ascend Performance Materials. “Respiratory viral illnesses, such as COVID-19, and the flu, are transmitted through droplets and aerosols. Polypropylene, the material in commonly used disposable masks, is a hydrophobic plastic and does not absorb moisture. Instead, the viruses can sit on the surface of the mask, posing a transmission risk when the mask is handled.”

-Cosmo Films announces expansion of Aurangabad plant

Cosmo Films has announced the expansion of its BOPP film production line at Aurangabad with an annual rated capacity of 67,000-MT. Once it becomes operational, it would be one of the world’s largest BOPP lines. The BOPP line will require an investment of about Rs 350-crores to be funded through internal accruals and debts and is expected to be commencing commercial production within FY 2024-25.

Backed by strong financial performance, the company has also declared its first interim dividend of Rs 25 per share for FY2021-22.

Pankaj Poddar, CEO, Cosmo Films, said, “With current capacity expected to produce primarily speciality films (80%+) in next two years and projected BOPP film demand growth in India, the company planned capacity expansion which will be world’s largest production line with annual rated capacity of 67,000-MT with lowest cost of production.”

-Regenerating plant for PP and HDPE

Clean-tech start-up Healix is building a circular fibre regeneration plant in the Netherlands, having secured funding totalling over €10 million in its seed financing round completed this month.

The Maastricht plant will shred, wash and reprocess used twine, ropes, nets and other plastic fibre waste from farming and fishing into pristine circular new polymers for the nonwovens and technical textiles industries. It is expected to be operational in the first quarter of 2022 and will have an annual capacity of 6,000 metric tons of polypropylene (PP) and high density polyethylene (HDPE), saving almost 10,000 metrics tons of CO2 emissions per year.

One of the most pressing issues the technical textile industry is facing, is the damaging effect of plastic fibre waste on terrestrial and marine ecosystems. Healix aims to combat this by transforming existing linear economies in the technical textile industry into sustainable circular economies.

-Free online Conference on Carbon Capture and Utilization (eCO2nference)

Join the free eCO2nference hosted by PKN Orlen and the BioRECO2VER project, 7 October (9:40 am – 2:15 pm) Biodegradable Polymer rPET Material

Within the framework of our H2020 project BioRECO2VER (www.bioreco2ver.eu) and on the occasion of the opening of PKN Orlen’s R&D Centre, we invite you to a free conference (eCO2nference) on “The future of CCU technology from a technical, political and social point of view in the world and Poland” on 7 October 2021 PKN Orlen’s R&D Centre in Płock, Poland (hybrid event).

In addition to the current market developments of CCU technologies and the political framework in Poland, Europe and the world, we would also like to present CCU innovations from laboratory-scale to semi-commercial scale as well as the latest findings on Life-cycle assessment and social acceptance from our BioRECO2VER project.

Biodegradable Polymer rPET Material