Biopolymers Petrochemicals WasteRecycling 02-07-2021 - Arhive

Biopolymers Petrochemicals WasteRecycling

Crude Oil Prices Trend

-July paraxylene contract prices in Asia are nominated at USD1,010-1,030 per tonne

Several major Asian paraxylene producers have announced their material contract prices for July shipments at USD1,010-1,030 per tonne, which is USD60-70 per tonne higher than the June contract price quotes, market sources told ICIS .

Prices were nominated on CFR Asia delivery terms.

Paraxylene contract prices for July were raised following the recent rise in spot prices for the material.

Thus, spot prices for paraxylene on June 28 were in Asia in the range of USD929-931 per tonne, CFR Taiwan / main ports of China (CMP) versus USD82-854 per tonne, CFR Taiwan / CMP, as of June 1, according to ICIS data.

The final result of the June agreement on paraxylene contract prices in Asia will be determined by the end of business day on June 30th.

Earlier it was noted that the participants in the negotiation process to agree on the June contract prices for paraxylene in Asia could not reach an agreement for the current month. Bids were in June at USD950-960 per tonne CFR Asia.

Paraxylene is a raw material for the synthesis of terephthalic acid, an intermediate product for the production of polyethylene terephthalate (PET).

-Plastipak’s Clean Tech and BioteCH4 form unique partnership to power recycling operation

Plastipak has teamed up with anaerobic digestion (AD) operator BioteCH4 to deliver a low carbon solution to power its Clean Tech PET recycling plant.

Based in Hemswell, Lincolnshire, BioteCH4 operates an anaerobic digestion plant, recycling over 90,000 tonnes of food waste per year. Anaerobic digestion is a complex biological process involving the breakdown of organic matter in the absence of air in large, sealed and insulated vessels with controlled heating and mixing.

Food waste enters a sealed building where it is processed into a liquid slurry and pumped into the anaerobic digestion plant. It is here that bacteria feed on the food waste and produce biogas. This biogas is captured and used as fuel in CHP (combined heat and power) engines to produce electricity or is sent through a gas filter and sent directly to the gas grid. Biopolymers Petrochemicals WasteRecycling

OPEC’s forecasts point to an oil supply deficit in August and in the rest of 2021 as economies recover from the pandemic, suggesting the group and its allies have room to raise output at a meeting this week, reported Reuters.

The Organization of the Petroleum Exporting Countries and allies, known as OPEC+, is returning 2.1 million barrels per day (bpd), about 2% of world output, to the market from May through July as part of a plan to ease last year’s record output curbs.Biopolymers Petrochemicals WasteRecycling

OPEC+ meets on Thursday to discuss supply for later months. With oil at its highest since 2018, sources say a further boost in August will be discussed, but some producers are wary about new demand setbacks and higher Iranian supply.

OPEC’s latest forecast of the demand for its crude suggests, if output levels stay the same, OPEC supply will fall short of expected demand by 1.5 million bpd in August. The shortfall widens to 2.2 million bpd in the fourth quarter.

Iran and world powers have been talking since April on reviving Tehran’s 2015 nuclear deal, which would allow Iran to boost output, so far without agreement.

-Freudenberg presents Evolon® made from post-consumer recycled PET

June 30, 2021 | Recycling technology | Freudenberg | Weinheim | Germany

With Evolon® RE, Freudenberg Performance Materials (Freudenberg) is now offering its customers an even more sustainable version of its high-performance microfilament textiles. Evolon® RE is manufactured from an average of 70% recycled polyester, which the company makes by recycling post-consumer PET bottles in-house. Evolon® RE is available for various applications, including high-tech wiping and technical packaging, in weights currently ranging from 80g/sqm to 300g/sqm. Evolon® RE offers the same high and constant quality as all other Evolon® textiles. This applies to mechanical and textile properties as well as to filtration, cleaning and protection properties. Biopolymers Petrochemicals WasteRecycling

The use of recycled materials in the demanding production of Evolon® textiles without sacrificing product performance underlines Freudenberg´s technological know-how, as Jean-Francois Kerhault, Business Segment Manager Evolon, explains: “We have more than 20 years of experience with Evolon® technology. Our technical teams are real experts in this demanding process, and it is thanks to their knowledge that we were able to overcome the challenge of integrating recycled PET from post-consumer bottles into our products.”

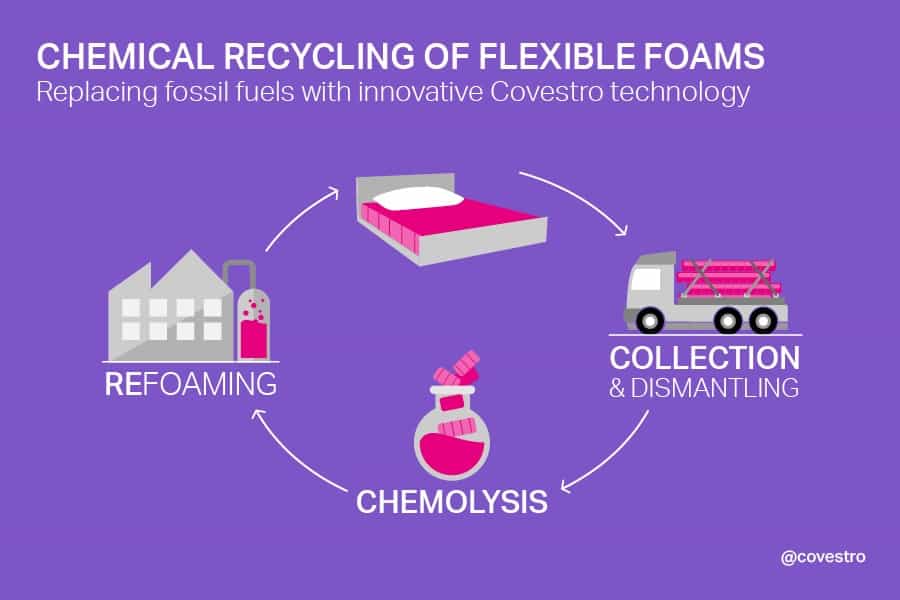

-Covestro works on sustainable material solutions and recycling technologies

Covestro is working towards innovative and more sustainable material solutions and recycling technologies to meet these requirements and build a Circular Economy, and will be showcasing them at the VDI PIAE 2021 international trade congress on September 8 and 9, said the company. Biopolymers Petrochemicals WasteRecycling

“Our aim is to introduce the world’s first climate-neutral polycarbonate plastics this year,” Jochen Hardt, Marketing Mobility Covestro, told media representatives. “This is an important step in achieving our vision of becoming fully circular. At the same time, we offer products and solutions that combine outstanding performance, cost efficiency and sustainability designed to help our customers in the mobility industry succeed in achieving their sustainability goals.”

The polycarbonates are climate neutral “from the cradle to the factory gate1” thanks to the introduction of raw materials sourced from mass-balanced biowaste and residues2, as well as renewable energy accumulated during the production process. Covestro is already offering ISCC Plus-certified polycarbonates, which are attributed to renewable raw materials using the mass balance approach and enable a considerable reduction in the carbon footprint.

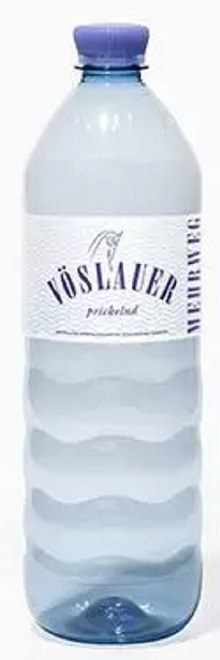

-ALPLA: New reusable PET bottle for Vöslauer

ALPLA is developing and producing a new reusable PET bottle for Vöslauer, Austria’s leading company in the mineral water market. The bottle is not only sustainable, but also light, stable and visually appealing. The new bottle will enter the market in early 2022. Biopolymers Petrochemicals WasteRecycling

The two family-owned businesses Vöslauer and ALPLA have been jointly championing sustainable solutions for years. The aim is for Vöslauer’s natural mineral water to come in packaging which is resource-conserving, light and suitable for everyday use. What’s needed are bottles with a modern design that combines innovation with aesthetics. Following the introduction of the 100 per cent rPET bottle (rPET = recycled PET) in 2018, the next step into the future will follow in 2022 with the new reusable PET bottle. As an expert partner, ALPLA is heavily involved in the development and production of Austria’s first modern reusable PET bottle.

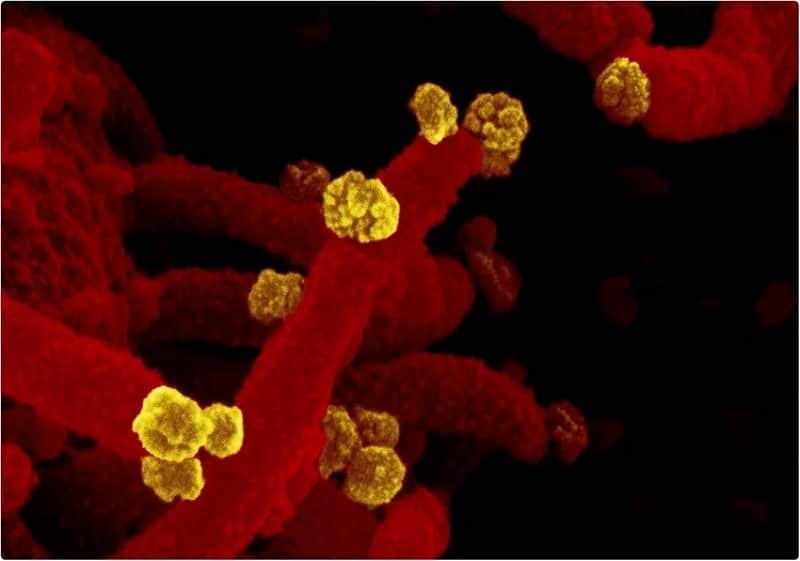

-Zinc-embedded polyamides inactivate SARS-CoV-2 and influenza A

Severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) and influenza A viruses (IAVs) can spread via liquid droplets and aerosols. These viruses can be prevented from spreading by wearing face masks or other personal protective equipment (PPE). However, IAV and SARS-CoV-2 are stable for hours on various materials. Thus, the frequent and correct disposal of these PPE becomes crucial and also requires decontamination processes for reuse.

Many studies report the use of silver nanoparticles, copper nanoparticles, cuprous oxide (Cu2O) or cupric oxide (CuO) spays, and copper or zinc surfaces or fibers to inactivate the virus; however, many confounding factors such as adsorption of viruses make it difficult to measure and optimize the inactivation characteristics.

In a recent study, interdisciplinary researchers demonstrated how they removed the IAV H1N1 and the SARS-CoV-2 from woven PA66 fabric to measure the number of remaining active viruses. Using this advancement, they found that a zinc-containing polyamide 6.6 (PA66)-based fabric decreased the IAV H1N1 and pandemic SARS-CoV-2 titer by approximately 2-logs (100-fold). Biopolymers Petrochemicals WasteRecycling

-“Polymer Group-Kaluga” plans to build a plant for the production of polyethylene film

The Polymer Group-Kaluga company will build a plant for the production of polyethylene agro-stretch films, covering films and bags at the Lyudinovo site of the Kaluga SEZ, the company said.

The investment in the project will amount to 180 million rubles. 111 new jobs will be created. The commissioning of the facility is scheduled for the end of 2022, the Agency for Regional Development of the Kaluga Region reported.

According to the company, the volume of the created production will cover up to 3% of the market for agricultural film produced in Russia. The project takes into account the requests of partner companies, and its implementation will fully cover their needs in this segment of products. Biopolymers Petrochemicals WasteRecycling

The approval of the application for obtaining the status of residents of the special economic zone “Kaluga” was adopted on June 22 at a meeting of the expert council chaired by the Deputy Governor of the Kaluga Region Vladimir Popov. The total investment in the two projects will amount to more than 570 million rubles.

Earlier it was reported that BASF and the Fabbri group of companies have developedbiodegradable film for food packaging. Based on ecovio, a certified biodegradable material from BASF, the Fabbri Group produces Nature Fresh, a highly transparent stretch film. This product is the first certified biodegradable film for foodstuffs, combining optimal breathability, long shelf life, high transparency and excellent mechanical properties for automatic packaging.

-GreenMantra Technologies expands recycling agreement with Crayola

Canadian recycling technology developer GreenMantra Technologies is expanding its relationship with art tools and toy supplier Crayola by now using Crayola’s discarded plastic feedstock for recycling into specialty polymers, said Canpastics.

“Mixed plastic marker streams present challenges for traditional mechanical recycling, but they are a natural fit for [our] advanced recycling technology,” officials with Brantford, Ont.-based GreenMantra said in a news release. “[We] will now recycle both pre- and post-consumer plastic markers from across all of North America, expanding our feedstock stream for producing our specialty polymer additives.”

The discarded plastic markers can be turned into high-value polymers that can then be used in the production of industrial products to enhance critical infrastructure applications (things like asphalt roads, roofing products, and plastic drainage pipes), while also enabling increased use of recycled content in those applications, the company said. Biopolymers Petrochemicals WasteRecycling

Easton, Pa.-based Crayola recently implemented 100 per cent renewable energy for its U.S. manufacturing operations, and has partnered with GreenMantra since 2014 through its ColorCycle Program, which enhances product circularity for Crayola’s line of markers.

-Commercial-Scale Chemical Recycling at Work

Nexus founder and CEO Jeff Gold discusses the company’s chemical recycling technology and process.

Converting partners of Nexus includes Royal Dutch Shell and Chevron Phillips among others. Biopolymers Petrochemicals WasteRecycling

Nexus, located in Atlanta, Ga., is an operational, commercially scaled converter of waste plastics to feedstocks, which in turn are converted back to virgin plastics.

The company recently announced it has entered into a strategic relationship with Wood, the global consulting and engineering company, to globally expand its advanced molecular plastics recycling business to meet significant market demand from global plastics producers. Wood will first assist Nexus with the expansion of its plant in Atlanta to better position the company for future phases of its global development.

Biopolymers Petrochemicals WasteRecycling