Biotechnology Plasticwaste Petrochemicals 24-05-2021 - Arhive

Biotechnology Plasticwaste Petrochemicals

Petrochemicals PETResin Spandex Trend

Crude Oil Prices Trend

-PlasticsEurope condemns the illegal trade of plastic waste

PlasticsEurope has condemned the illegal dumping of plastic waste and called for stricter enforcement of the controls on its shipment.

The European plastics manufacturers trade organisation described the act as ‘distressing’, particularly for countries that lack appropriate waste enforcement capacities and suitable infrastructure to prevent the trade of illegal waste. PlasticsEurope continues to work collaboratively with enforcement authorities to tackle this issue. Biotechnology Plasticwaste Petrochemicals

A recent press statement read: ‘The Interpol report on illegal plastic waste exports issued in August 2020 flagged a significant increase in plastic waste crime. We welcomed the Report’s conclusions and have expressed since then the urgency to increase enforcement of existing global and national legislation on waste trade which PlasticsEurope fully backs.’

Virginia Janssens, PlasticsEurope Managing Director, said: “More radical measures are needed to stop this issue. This is why we also urged the international community to step up the development of efficient monitoring systems to tackle the lack of waste traceability and to improve collection of reliable data.”

-INEOS and LACTEL partner to produce the world’s first HDPE Milk Bottles from advanced recycling

– INEOS and LACTEL announce a partnership on advanced recycling packaging for dairy products.

– Advanced recycling enables conversion of waste plastic back to new, high-quality polymers, used to produce the Lactel bottles.Biotechnology Plasticwaste Petrochemicals

INEOS O&P EUROPE is making a significant investment to develop a comprehensive portfolio of circular solutions for the packaging industry. The collaboration with LACTEL is yet another major milestone in this direction.

Advanced recycling technology converts waste plastic back to its basic molecules which are then used in INEOS production sites to include recycled contents and replace traditional fossil-based raw materials.

LACTEL is the first dairy brand, in collaboration with INEOS, to explore a solution for UHT milk bottles produced with circular polyethylene, derived from post-consumer recycled material.

-Avantium in sweet deal for plant-based glycol

Avantium is to work with a Dutch sugar beet processor on commercialising plant-based glycol production from sugars, after successfully demonstrating the process at its pilot plant.

The biopolymers firm has teamed up with Cosun Beet Company (CBC), part of Royal Cosun, with the aim of jointly constructing and operating the first commercial plant using Avantium’s Ray Technology.

Ray converts sugars into plantMEG, which is used in packaging and textiles. It also produces plantMPG, which offers benefits in industrial applications such as heat transfer fluid for solar panels.Biotechnology Plasticwaste Petrochemicals

Avantium currently produces plantMEG and plantMPG at its pilot plant in the town of Delfzijl, with beet sugar supplied by CBC. Validation of the functional performance of the plant-based glycols was only confirmed in April.

The company said its current collaboration with CBC served as a “strong foundation” for the envisioned joint venture business.

The joint venture is to be formalised this year, and an investment decision for the commercial plant is anticipated to be made in the first half of 2023. It is hoped commercial operations can commence in 2025.

-Polymer Points: Resin price volatility continues in April

The rise of the resins continued in April as tight supplies of materials continued to be a challenge for processors across North America.

Regional selling prices for polyethylene, PVC, polystyrene and PET bottle resin all were up for the month. Average polypropylene resin prices were down because of operating conditions, while demand for that resin remained high.

Regional prices for low and linear low density PE surged an average of 9 cents per pound since April 1, with high density PE prices up 7 cents. Supplies of the material remain tight as producers look to recover from outages caused by Winter Storm Uri in February.Biotechnology Plasticwaste Petrochemicals

The April HDPE price increase at first was believed to be 9 cents, but the market eventually settled up to 7. This change is being shown as a 2-cent downward correction on this week’s Plastics News resin pricing chart.

PE prices now are up a total of 28 cents so far in 2021 and are up 48 cents since January 2020. PE makers are seeking increases of 5-6 cents per pound for May.

Many producers still are operating under force majeure sales limits or other types of sales allocations. On average, North American PE processors are receiving 70 percent of their requested purchases, according to sources contacted by Plastics News.

Mike Burns, a PE market analyst with Resin Technology Inc. in Fort Worth, Texas, said that allocations are moving higher than 70 percent but that demand is still exceeding supply. c

-How the Circular Economy Can Transform Manufacturing

Four essential changes need to occur before your company can reap the rewards of this economic shift.

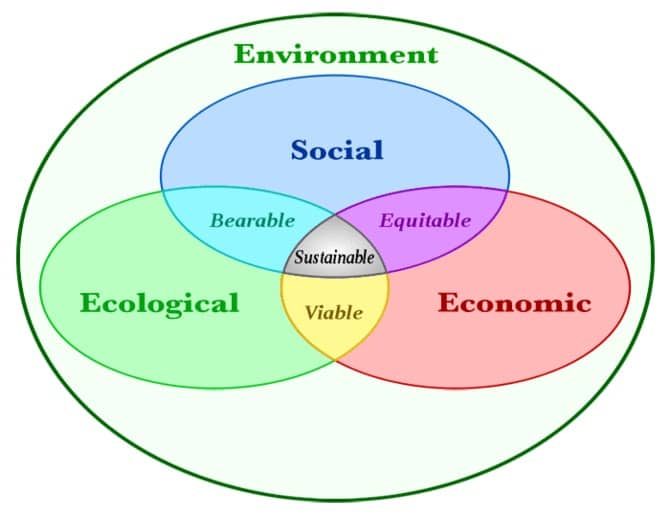

In a resource-constrained world, there is a noticeable trend of companies opting into the circular economy model. For manufacturers, this shift involves a move away from the “take-make-dispose” linear economy and a step towards increased responsibility over the total lifecycle of a product and its environmental impact. But to close the loop, manufacturers need to embrace change and learn to adapt their processes and products.Biotechnology Plasticwaste Petrochemicals

Circular economy, set to be the biggest revolution in the global economy in 250 years according to Accenture, is part of the ongoing narrative on industrial sustainability. Recent economic factors such as input cost rises and resource volatility have heavily influenced this shift towards a circular approach, but not all the reasons are reactive.

With a circular business model, manufacturing companies can achieve stronger value chain relationships and yield long tail revenues. But to reap the rewards, this shift requires change. As more companies opt into the circular economy and product lifecycles increase, manufacturers will not only need to re-examine and re-configure their operations, but also explore how they adapt their ERP solutions to meet the new demands required by these sustainable models.

In particular, there are four key areas where the impact of the circular economy in manufacturing is clear to see.

-Biotechnological circular solutions

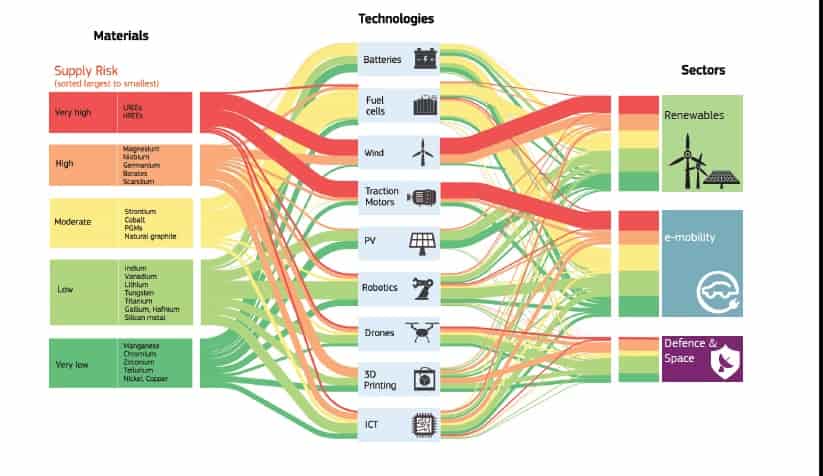

The BIORECOVER project is developing biotechnological circular solutions to tackle the supply of some critical raw materials in the EU Biotechnology Plasticwaste Petrochemicalsls

According to the European Union (EU), Critical Raw Materials (CRMs) assemble a list of 30 metals, minerals and natural materials which are crucially impacted in economic terms by a high supply risk. CRMs are essential to produce a broad range of goods and applications for several industrial ecosystems.

Rare Earth Elements (REE) and pure magnesium almost entirely rely on imports from China, 98% and 93%, respectively. Moreover, the demand of both CRM comprises strategic and growing sectors, such as renewable energy, high-tech application, automotive, etc. Additionally, the production of REE and Mg from secondary raw materials makes only a marginal contribution to the EU’s demand, being a huge loss of value to its economy. It is capital to unlock unexploited sources of these raw materials to reduce dependency and strengthen diversity and security of supply in the EU.

The main producers of Platinum group metals (PGM) are South Africa (84%) and Russia (40% for palladium), with an absolute reliance of 100%. Although 50% of platinum is recycled, covering more than 25% of the EU’s consumption, the growing demand in applications such as fuel cells and electronic devices makes necessary process development to increase its recyclability. Achieving strategic partnerships with resource-rich countries and working together to ensure maximum yield of these resources is capital, always making use of external policy instruments and respecting its international obligations.

-Plastic scrap prices rise amid tight supply

Reprocessors say obtaining enough scrap to meet demand for postconsumer resin has been difficult.

Whether you’re talking polyethylene terephthalate (PET), high-density polyethylene (HDPE) or polypropylene (PP) scrap, supply has tightened, while pricing has increased to new highs. Biotechnology Plasticwaste Petrochemicals

One PET reprocessor based in the Northeast says bale supply is “very tight,” and pricing is increasing as a result. High-grade PET bales have reached 30 cents per pound in California, while pricing is in the 20-cents-per-pound range in the Midwest and Southeast as of the third week of May, he says.

His company has offered to raise its pricing to draw in more material, but the supply is not available. “The collection rate is poor but starting to improve.” He says that is in part because cooler weather has lingered in the Northeast, affecting generation of water and soft drink bottles.

“We are fighting over every bottle out there,” the reprocessor says. “There is not enough material now to go around.”

Demand for his company’s rPET flake also has increased, which he says is a very different situation from late 2020. “There was almost no demand for this stuff,” he says, adding that his company was inventorying a great deal of material as a result.

But demand started to grow in March, he says. “People are falling over themselves to try to buy this stuff. It’s gotten a little nuts.”

Graphene and related materials demonstrated a broad range antimicrobial activity. This is attributed mainly to the direct physicochemical interaction between germs and microbes, which makes it more effective than conventional surface disinfectants.

Shahid Akhter, spoke to Vikas Bardiya, Founder, Nanomatrix Materials, Bardiya Group, to know more about graphene and its application in healthcare by way of antimicrobial activity toward bacteria, fungi and viruses.

Graphene industry and the technology Biotechnology Plasticwaste Petrochemicals

Graphene is 1 atom thick sheet of carbon in a honeycomb crystal hexagon. It is one of the most exciting subjects for researches as it possesses tremendous properties and can be used in almost every application in the world. It is the strongest material in the world which is 200 times stronger than steel and 20 times lighter than a feather. This is the best conductor of electricity and best thermal insulator.

There are a number of applications where graphene has gained its most attention, be it Rechargeable batteries, polymers, textile, construction and most recently in healthcare.

-Does sustainability mean anything anymore?

Packaging brand owners risk slowing the momentum of sustainability gains as a result of greenwashing, argues David Harding-Brown, CEO at Ecoveritas, in our latest comment feature.

‘Sustainability’, ‘eco-friendly’, ‘green’, ‘ethical’, and ‘ecological’ are all terms we use daily without questioning why. They have become so easy to associate with environmental messaging that their original meaning has now become lost in the ‘white noise’ of consumer marketing. This ongoing experience of semantic satiation across the packaging supply chain needs to stop, otherwise brand owners risk slowing the momentum of sustainability gains. Biotechnology Plasticwaste Petrochemicals

Fortunately, there are many brands out there making their mark on sustainability with meaningful action. It is true that they are driving pertinent and powerful messaging, but they are, in turn, quantifying this with measurable data and innovating in their design for environment (DFE) business strategies. However, not all brand owners are doing their part. There are some that are squandering these values and undermining the work of those brands that are driving positive change in the industry.

Biotechnology Plasticwaste Petrochemicals