Blown Film Bioplastic Petrochemicals 09-06-2021 - Arhive

Blown Film Bioplastic Petrochemicals

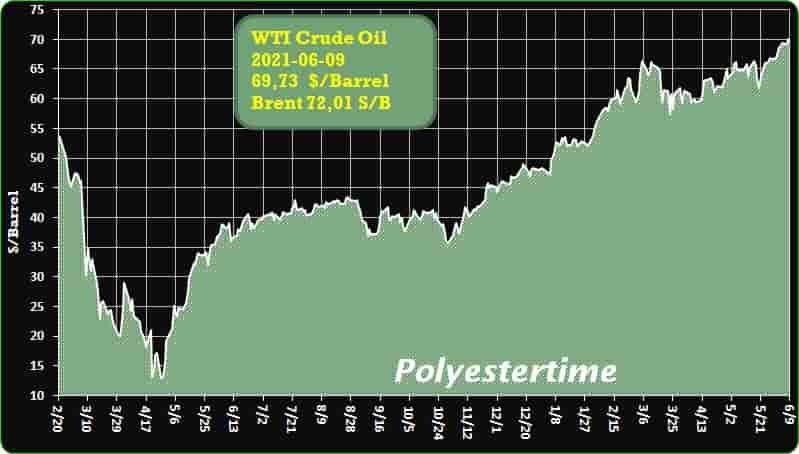

Crude Oil Prices Trend

-Hyosung plans Vietnamese PP start-up after PDH unit

South Korean polymers producer Hyosung plans to start operations at its second 300,000 t/yr polypropylene (PP) unit at Ba Ria-Vung Tau only after starting up its propane dehydrogenation (PDH) unit at the Vietnamese petrochemical complex. The PP unit is likely to begin operating in this year’s late third or early fourth quarter.

Hyosung is expected to start its new PDH unit with a nameplate capacity of 600,000 t/yr of propylene around July-August, according to market participants.

Hyosung signed an agreement with the Vietnamese government to build a $1.2bn complex in Ba Ria-Vung Tau province in early 2017. It will comprise a 600,000 t/yr PDH unit, two 300,000 t/yr PP units and LPG storage facilities. Its first 300,000 t/yr PP unit started operations in March 2020 using imported propylene.

Vietnam relied on imports for around 90pc of its PP consumption in 2020. The country has always been a key target for China’s PP exports to southeast Asia because of its high PP consumption and import dependency, as well as its location bordering China.

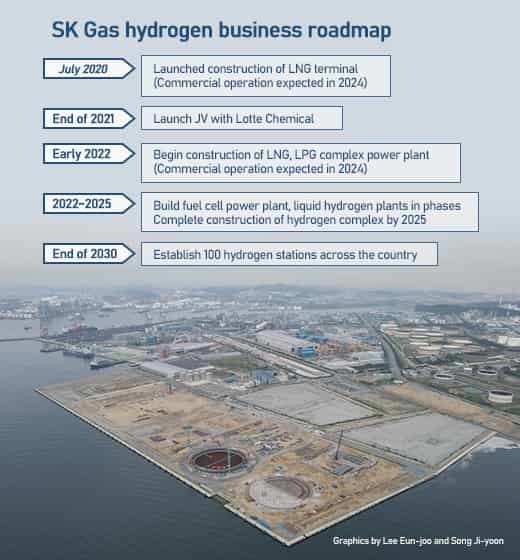

-SK Gas creating multibillion-dollar hydrogen produce infrastructure across Ulsan

South Korea’s third largest conglomerate SK Group is fielding SK Gas Co. to command hydrogen business to build it up as its green growth engine along with rechargeable battery. Blown Film Bioplastic Petrochemicals

According to multiple industry sources on Monday, SK Gas is spending billions of dollars to establish a hydrogen value chain complex along the southern coast of Ulsan City by 2025.

The company will be in charge of creating a comprehensive hydrogen economy from import of raw materials and production to storage and distribution.

The mammoth project is expected to cost several billions of dollars and shift the company’s mainstay in LPG and LNG business to hydrogen.

South Korea is going all-out on hydrogen economy to make the clean fuel its primary energy source over nuclear and fossil fuel. The state-led push has engaged most of the key companies including SK, Hanwha, and GS.

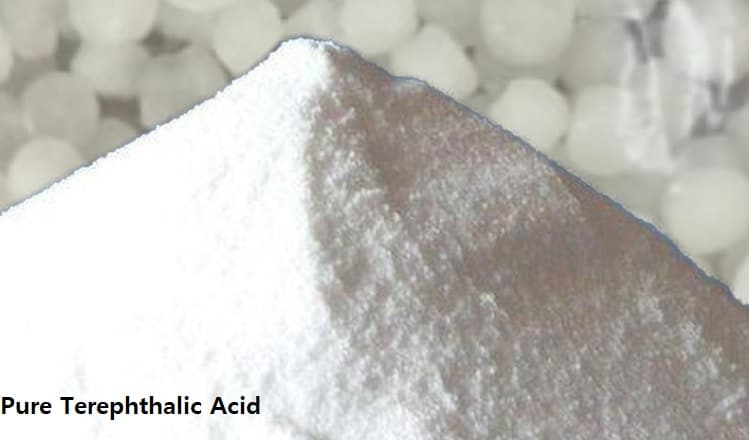

-PX under strains from unexpected supply increase

PX price was under pressure, relatively weaker compared to the feedstock crude oil and naphtha. PX-naphtha spread narrowed fast to $221.6/mt on Jun 3 and further to $212.4/mt on Jun 4. The spread was squeezed heavily, with feedstock price rising, as PX supply was ample in China domestic market recently. Then, there did those supplies come from? Blown Film Bioplastic Petrochemicals

- China PX imports staying high

In Jan-Apr, China PTA capacity expanded, however overall PTA output was scaled back as plants cut operating rates due to losses. Though China domestic PX output reduced over the same period, the imports kept increasing, leading to mounting PX inventory.

- Delays of the startups of fresh plants

It was earlier planned that a new 3.5 million mt/yr PTA plant and a new 2.5 million mt/yr PX would start in the second quarter of 2021. The fresh PTA plant was scheduled to start one month ahead of the PX plant, so the PTA producer had already stocked PX in advance. However, both plants were postponed, and the interval between the startups was shortened and the PX plant may even start ahead of the PTA plant. As a result, PX inventory in that PTA producer were quite high.

-Lenzing welcomes EU’s positioning in fight against plastic waste

Lenzing Group, the Austrian supplier of sustainably produced specialty fibres, has welcomed the issuance of the guidelines for the implementation of the Single-Use Plastics Directive, which took effect on June 05, 2019. In these guidelines, the EU Commission specifies that wet wipes and feminine hygiene products fall within the scope of the directive. Blown Film Bioplastic Petrochemicals

The Commission implementing the regulation applying to the Single-Use Plastics Directive stipulate uniform labelling requirements for some of the single-use plastic products on the packaging or the product itself starting on July 03, 2021. They encompass feminine hygiene products and wet wipes for personal and household care containing plastic.

-Italian Machine Builder GAP Installs 27-Layer Blown Film Line

Systems consists of nine extruders feeding 400-mm annual die, an automatic gauge-controlling air ring, and other features.

GAP, a film-extrusion machine builder based in Trecate, Italy, has recently installed a 27-layer microlayer blown film line in its R&D center. The new line is comprised of 9 extruders and a 400-mm, annular coextrusion die capable of producing film in layflat widths to 1600 mm. The line is also equipped with an automatic air-cooling ring control and all new software control systems. Blown Film Bioplastic Petrochemicals

To date, GAP (gapitaly.com) has tested several structures on the microlayer line, both with blocks and alternating layers, and is said to have generated film with good mechanical properties at overall film thickness of around 20-25% thinner than the industry standard.

-Dust-Tight Batch-Weigh System

System integrates conveying and weighing for speed and accuracy.

The new Batch-Weigh System from process equipment manufacturer Automated Flexible Conveyor, Clifton, N.J., automatically transfers, weighs, and dispenses precise amounts of powders, pellets, flakes, and other bulk materials into mixers, hoppers, tanks, vessels and containers.

Achieving 99% or better batch weighing accuracy, the Batch-Weigh System replaces manual and semi-automated processes with a fully automated approach that eliminates the potential for operator error, increases throughput, and promotes batch-to-batch product consistency. Blown Film Bioplastic Petrochemicals

Costly material waste and quality control concerns due to over- and/or under-weighments are eliminated.

-Lucozade producer invests £6m to support recycling its bottles

Suntory Beverage and Food Great Britain & Ireland (SBF GB&I) is investing £6m to support the recycling of its bottles by renovating the packaging of its Lucozade brand.

Lucozade is produced at the company’s Coleford factory and millions are being invested to ensure that the Lucozade Sport bottle is only made from recycled plastic.

This alone will save 3,400 tonnes of virgin plastic being produced annually. Alongside this, the bottle will be redesigned with a smaller label – reducing the volume of plastic used previously and ensuring that every bottle can be recycled back into another bottle.

Although they’ve always been recyclable, the new labels which feature on-pack recycling prompts, ensure that the bottles can be sorted into the clear waste stream to be recycled back into bottles at UK recycling centres.Blown Film Bioplastic Petrochemicals

In total the changes represent a saving of 3,500 tonnes of virgin plastic and 9,000 tonnes of CO2, contributing towards the company’s net zero ambition.

-Dekko ISHO Group invests in Ecovia

Ecovia’s key vision is to tackle the irresponsible consumerism causing climate crisis, by bringing eco-friendly alternatives to single-use plastics

Dekko ISHO Group, one of the leading Bangladeshi conglomerates, signed a monetary and strategic capital investment agreement with Ecovia, a bioplastic initiative with its innovation in compostable polymer, led by three young entrepreneurs from Dhaka.

The ceremony took place in Dekko ISHO’s corporate office, said a press release.

Prottoy Hossain, director of Dekko ISHO Group, and Rashik Hassan, Riasat Zaman, and Ashfaqul Azam, co-founders of Ecovia, attended the program.

Ecovia’s key vision is to tackle the irresponsible consumerism causing climate crisis, by bringing eco-friendly alternatives to single-use plastics.Blown Film Bioplastic Petrochemicals

-Is PDK a resin of the future?

Berkeley Lab researchers in California say their new plastic resin is designed for optimal chemical recycling results.

Researchers affiliated with the Lawrence Berkeley National Laboratory in Berkeley, California, say momentum is growing for the wider adoption of a new plastic resin that “has all the convenient properties of traditional plastics [and] can be recycled indefinitely with no loss in quality.” Blown Film Bioplastic Petrochemicals

Two years ago, a Berkeley Lab research team led by Brett Helms announced the invention of poly diketoenamine (PDK), which it said could be “disassembled into its constituent parts at the molecular level, and then reassembled into a different shape, texture and color repeatedly without the loss of performance or quality.”

As investments in chemical recycling are being increasingly made in the United States and globally, Helms and a team of fellow researchers that includes Corinne Scown, Jay Keasling, and Kristin Persson have released a study they say shows “PDK-based plastic could quickly become commercially competitive with conventional plastics, and the products will get less expensive and more sustainable as time goes on.”

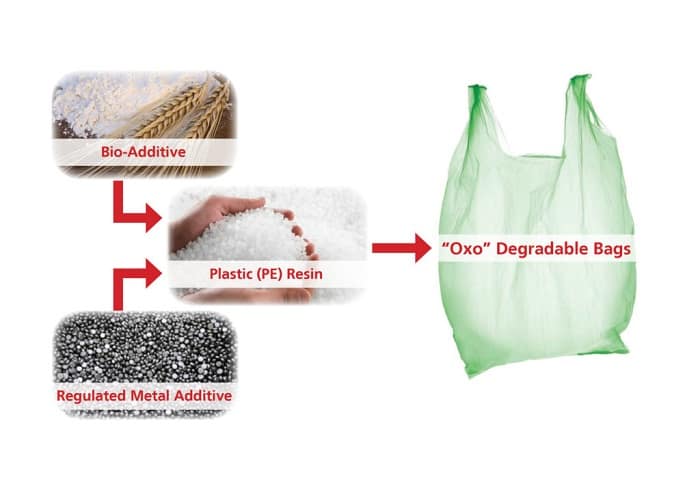

-Oxo-degradable plastics worry firms

Plastic manufacturers under the Federation of Thai Industries (FTI) are concerned about the increase of oxo-degradable plastics, which falsely claim to be environmentally friendly. Blown Film Bioplastic Petrochemicals

Oxo-degradable plastics are designed to break down into small fragments, but this causes microplastic pollution that harms ecosystems, including oceans.

Usage of plastic is increasing as a result of measures to curb Covid-19 infections, including travel restrictions and work-from-home guidelines. This has caused more people to order food, beverages and products online, resulting in more plastic packaging waste.

Even worse, some plastic makers who mix oxo-degradable additives in their products have alleged their plastics can decompose in a natural and environmentally friendly way, said Apiphop Phungchaikul, vice-chairman of FTI’s Plastic Industry Club.

Blown Film Bioplastic Petrochemicals