Carbon-Fiber – Recycling-technologies 14-05-2022 - Arhive

Carbon-Fiber – Recycling-technologies

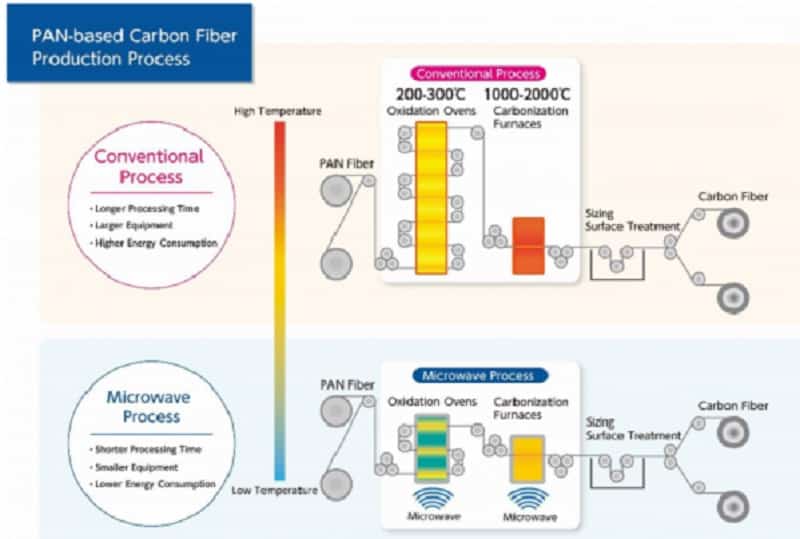

-Microwave Heating Slashes Energy Use in Carbon-Fiber Production

The new process is 50% more energy-efficient than the conventional method, which employs oxidation ovens and carbonization furnaces.

Japanese firms Mitsui Chemicals and Microwave have developed what they call “an innovative, eco-friendly carbon-fiber (CF) manufacturing technology using microwaves.” The new process employs microwaves to heat the polyacrylonitrile (PAN) fiber precursors, both during the oxidation process — the most energy-intensive part of CF production — and during subsequent carbonization.

As well as employing more compact equipment, the new technology cuts energy consumption by approximately 50% and offers a substantial reduction in processing time compared with the conventional method, which utilizes oxidation ovens heated from 200° to 300°C and carbonization furnaces maintained at temperatures of 1000° to 2000°C.

Microwave heating is efficient in that it is direct and selectively focuses on the PAN fibers alone. Conventional heating, on the other hand, is indirect and heats the entire oven or furnace.

The EREMA Group, which comprises EREMA Group GmbH and its subsidiaries EREMA, PURE LOOP, UMAC, 3S, KEYCYCLE and PLASMAC, closed the 2021/22 financial year with a 17 percent increase in revenue. Consolidated Group revenue amounted to EUR 295 million, and the number of employees increased to over 840. The EREMA Group remains on course for continued growth. Carbon-Fiber – Recycling-technologies

“This past financial year, we again set several milestones with growth powered by our technology. We are very proud of this, because the prevailing market conditions were once again very challenging due to corona, cost increases for energy and logistics, and interruptions to the supply chain,” is how Manfred Hackl, CEO of EREMA Group GmbH, sums up the year.

A total of 220 extruders manufactured in Ansfelden were supplied to customers all over the world. If you include individual components and modules such as filter systems and ReFresher anti-odour technology in that figure, the total was around 320. Then there are another 53 extruders from PLASMAC, the Italian subsidiary. The recycled pellet production capacity of all extrusion systems delivered in financial year 2021/22 adds up to around 1.34 million tonnes per year.

Trend towards large-scale plants

A closer look at the post consumer segment clearly shows a trend towards larger plants, both for PET recycling and for processing polyolefins. For example, the first VACUREMA® Basic 2628 T machine with an annual capacity of up to 40,000 tonnes was recently commissioned at a customer’s site in Brazil. This plant features a ten-meter-long special geometry screw with a diameter of 280 millimetres and a weight of 3.5 tonnes. The screw was developed and manufactured by 3S, a subsidiary of EREMA GmbH. “The move up to this scale of recycling machines is also clear proof of how much innovative power and know-how there is in our group of companies and the synergy effects this creates,” says Hackl. Carbon-Fiber – Recycling-technologies

Demand for previously-owned machines at UMAC also remained high during the past financial year. In addition to the general trend towards plastics recycling, the decisive factor here is that customers are more frequently opting for previously-owned systems available at short notice due to the tense situation on the procurement markets. At the same time, businesses that have so far had little contact with recycling are also becoming increasingly interested in this topic.

–Microwave-Heating Slashes Energy Use in Carbon-Fiber-Production

–Heraeus invests for a majority share in PET-recycling firm

–Plastics-Recyclers-Europe reports a 13% increase in installed plastics-recycling-capacity

–ACE-Green-Recycling to build 400,000 square foot battery-recycling facility

–OMV in talks to take over DSM’s–engineering-materials

-Another record quarter for Indorama-Ventures