Cellulose films – Chemical recycling 31-03-2023 - Arhive

Cellulose films – Chemical recycling

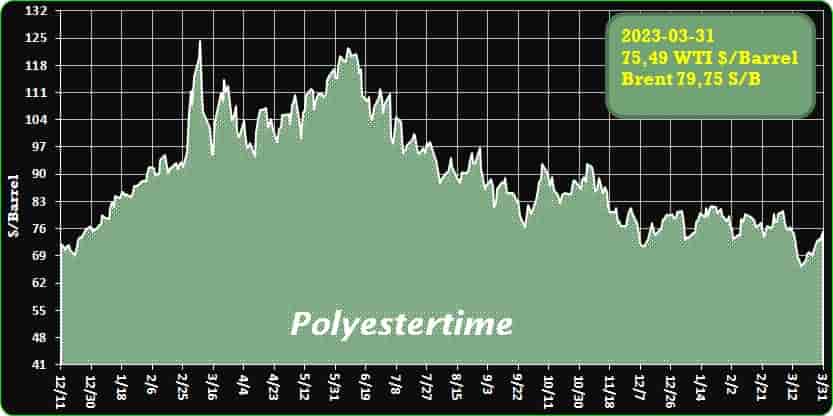

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-VTT investing €1.5 million in cellulose films

The new films could replace conventional blast in 5 years

Espoo-based VTT Technical Research Centre of Finland is investing €1.5 million into its CelluloseFilms pilot facility, where it produces renewable cellulose films designed to replace conventional plastic ones in packaging.

The investment will enable the institute to test and develop methods to scale up the production of these films, with the aim of making ‘sustainable materials more mainstream in an industry heavily reliant on packaging materials’, said Ali Harlin, who is a research professor at VTT.

“Polypropylene film is one of the world’s most used polymers and the market is expected to grow by €15 billion by 2035. It’s so useful in keeping food fresh that the world can’t do without it,” harlin added. Cellulose films – Chemical recycling

These transparent plastic films have been used in packaging for decades to protect food and minimise waste. The problem is that they are difficult to recycle because of the multi-layer, multi-material structure from which they derive their protective properties. These layers are unable to be separated, which means that, at the end of life, such packaging usually ends up in landfills. Yet, to date, no other viable, sustainable alternative is available on the market.

At VTT’s pilot facility, researchers are therefore working to develop easily recyclable cellulose-based film-like materials for food packaging and bio-based barrier materials for films, paper and cardboard.

Plastic wraps have been absolutely essential to the packaging industry since the 1940s, but the world is well overdue for a better alternative, Harlin pointed out.

“So far, we have received feedback from our customers that they can’t tell the difference between our cellulose-based films and traditional plastic wraps.” Cellulose films – Chemical recycling

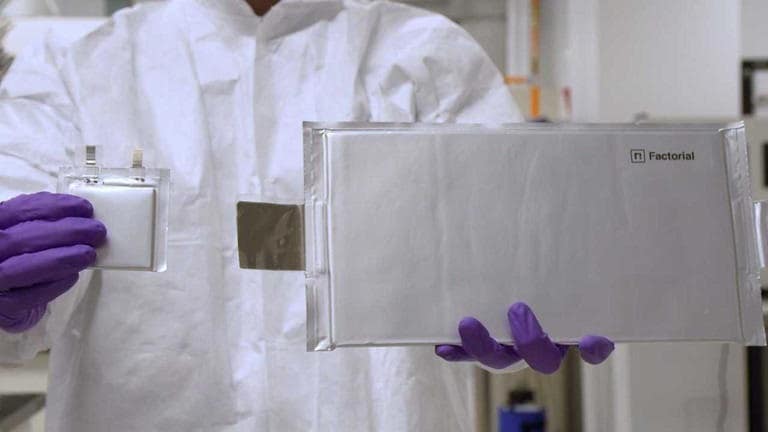

-Factorial’s solid-state battery arrives in Europe

The American company opens an office in Germany: in this way it supports European customers and exploits the excellence of the continent

Factorial Energy, a US company operating in the field of solid-state batteries, has decided to open an office in Europe. The new headquarters in the Old Continent will be located in Germany and more precisely in Munich.

The choice is not accidental, given that among the partners with which Factorial works most closely there are, in addition to Stellantis, also Mercedes and Hyundai-Kia Europe. However, they let it be known from the American company that the new headquarters will not be a real branch, but only an office with a team of dedicated people who will be able to work more closely with European companies. Cellulose films – Chemical recycling

A profitable exchange

Factorial’s landing on this side of the Atlantic has two objectives. If, on the one hand, the company wants to expand and consolidate its presence in Europe as well, on the other, it wants to exploit the skills that are found in Europe in terms of engineers, technicians and research institutes, in order to accelerate the development of own products and offer the market batteries with the best features.

In an official note, Factorial is well aware “of the advanced automotive skills of the region and the presence of prestigious universities and has every intention of establishing fruitful relationships to develop and test its products jointly”.

Siyu Huang, CEO of Factorial, adds: “Our presence in this region is strategic. The European Commission is considering new rules on battery sustainability and is promoting initiatives such as the Battery Passport and the Green Deal to accelerate the adoption of electric vehicles. Being here will allow us to better adapt to new situations and be able to respond faster to the needs of the market and our partners”. Cellulose films – Chemical recycling

A global presence

Factorial’s arrival in Europe follows that in South Korea and Japan last year. Also in 2022, the American company started the construction of a new Gigafactory based in Methuen, in the suburbs of Boston, financed with a fundraising round that brought a good 200 million dollars into the company’s coffers.

Factorial has attracted so much capital because since 2021 it has been working on a solid electrolyte battery of its own design that promises great energy density, greater safety and also lower costs than equivalent products because it can be built on existing lines of normal batteries lithium ion.

-Benefits from circularity way more than just environmental

Circular model will improve the performance of the plastic industry’s supply chain

Plastics have become ubiquitous in our daily lives, and their production has been on the rise for several decades. However, the negative impacts of waste from the plastic industry on the environment and human health are becoming increasingly apparent. Growing awareness of the environmental toll linked to the plastics industry has driven increased calls for the adoption of more circular systems in the plastics industry.

The aim of a circular economy is to keep resources in use for as long as possible by minimising waste, promoting recycling and reuse, and eliminating waste and pollution. In the context of the plastics industry, circularity would mean reducing plastic waste and pollution by keeping plastic materials in use for as long as possible while also re-evaluating our methods for sourcing plastic raw materials. Cellulose films – Chemical recycling

Moving to more circular economic and operational models will require a fundamental shift in the way plastics are designed, produced, used, and disposed of. The shift will require collaboration among stakeholders across the supply chain, including producers, manufacturers, retailers, and consumers. This will involve the development and implementation of technologies and processes for designing and producing more sustainable plastic products, promoting the recycling and reuse of plastic materials, and implementing new business models to profit from a circular economy.

The benefits of a circular economy

What’s the incentive for the plastic industry to adopt circular practices? Let’s take a closer look at how the adoption of circularity can benefit businesses, particularly in the specific area of supply chain management.

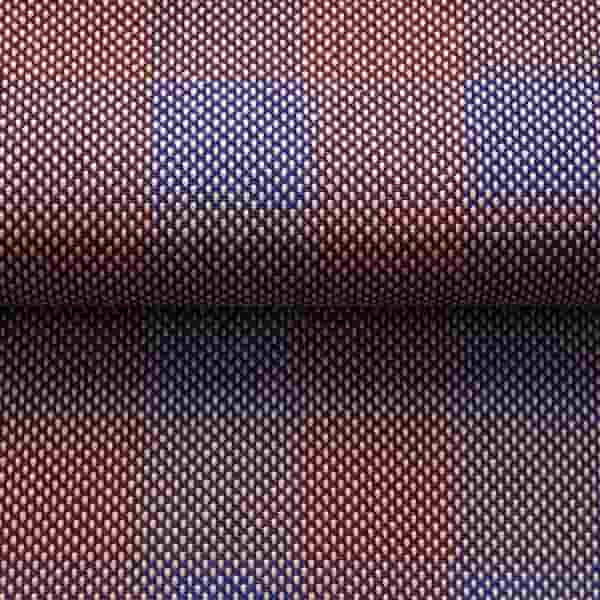

-Kvadrat, Avantium sign PEF offtake agreement

PEF yarn hold promise for a fossil-free future

Renewable chemistry company Avantium N.V., has signed an offtake agreement with Denmark’s textile specialist Kvadrat A/S. Kvadrat will purchase polymer PEF, short for polyethylene furanoate, from Avantium’s FDCA (furandicarboxylic acid) Flagship Plant, which is currently under construction in Delfzijl, the Netherlands. Commercial production of the 100% plant-based and fully recyclable material is set to start in 2024.

The collaboration ‘highlights the further potential of PEF across different application areas, including textiles, enabling the commercial launch of PEF and introducing it to everyday life’, said Tom van Aken, CEO at Avantium.

The offtake agreement will give Kvadrat a head start in creating PEF-based textiles for both commercial and residential interiors. Cellulose films – Chemical recycling

The Danish textile expert committed last June to transitioning towards a fossil-free future in the textile industry and, among other things, joined the PEF Textile Community to explore the possibilities of the use of PEF yarns in high-quality textiles. Several successful trials later, it decided to secure a supply of PEF by entering into the present offtake agreement, which will now allow Kvadrat continue its efforts to create sustainable and high-performance PEF-based textiles.

Anders Byriel, CEO at Kvadrat said that as part of Kvadrat’s ‘Regenerate Together through Transparency’ sustainability strategy ,the company is focused on the use of renewable materials as the basis for all its products. “Our ambition is to lead the sustainability agenda in the textile industry,“ he noted.

Kvadrat was established in Denmark in 1968 and has deep roots in Scandinavia’s world-famous design tradition. Cellulose films – Chemical recycling

-Fast chemistry takes on fast food

The University of Birmingham and engineering firm Stopford announce new funding for novel plastics recycling technology

The technology is a chemical recycling process that utilises hot compressed water as green solvent to selectively depolymerise waste plastics into commodity compounds which can be processed to produce virgin materials.

A research consortium comprising technologists from the University of Birmingham and engineering firm Stopford has been awarded a further £300k of funding from Innovate UK to develop a novel plastic recycling technology.

The technology is a chemical recycling process that utilises hot compressed water as green solvent to selectively depolymerise waste plastics into commodity compounds which can be processed to produce virgin materials – supplanting fossil fuel feedstocks and injecting much-needed circularity in plastic wastes management. Importantly, it is capable of recycling contaminated and degraded plastics, and requires reduced downstream processing. Cellulose films – Chemical recycling

To accomplish this, the process exploits the unique behaviour of water in its supercritical state (above a certain temperature and pressure) where it exhibits reduced polarity, high solvating power for complex polymers (like plastics). By virtue of combined intermediate heat and high pressure, it decomposes polymers at ‘selective spots’, thus producing target products at high proportions.

“Supercritical water technology is exciting, intriguing, and challenging. We are dedicated to remain on the road of alleviating the upcoming challenges with science, engineering, and with working as one team of complementing skills.

Professor Bushra Al-Duri from the School of Chemical Engineering at the University of Birmingham, and inventor of the platform technology”

The new tranche of funding has been awarded by UK Research and Innovation’s Smart Sustainable Plastic Packaging Challenge to adapt our platform technology to PET-based plastic waste such as pots, salad trays, and tubs. It complements the team’s on-going work, also funded by Innovate UK, to establish a demonstrator facility at Birmingham’s Tyseley Energy Park for the recycling of polyolefin-based plastics, such as polyethylene and polypropylene which are used in packaging. Cellulose films – Chemical recycling

Dr Ben Herbert, Technology & Innovation Director at Stopford, said: “I am delighted that our technology has once again been recognised by UKRI’s SSPP Challenge as a ground-breaking recycling technology for the management of waste plastics, and I very much look forward to working with our project partners to expand its application to enable a circular approach to the management of PET-based plastics waste.”

-PP contracts poised for another price increase

March PP contracts are set for another sizable increase, which will add to the $0.18/lb cost-push hike already implemented in January and February, minus some margin contraction that has varied by producer.

Spot PGP prices have retreated sharply from peak levels seen earlier this month, reining in early estimates for the pending increase. Late in the week, one index suggested that PGP would still see a $0.13/lb increase, but with April monomer well-discounted to prompt, leaving next month vulnerable, even a dime increase for March would be plenty, according to the PlasticsExchange. Cellulose films – Chemical recycling

Market participation was heavy in ethylene, and propylene dealings were relatively light, with overall volume solid as prices diverged. The trading week began very quietly but gained steam with news of the unplanned outage at Nova, which has annual production of 1.8 billion pounds of ethylene. On Tuesday, ethylene for prompt delivery changed hands in Louisiana at $0.1825/L.

-Azoty Police signs deal for USNC micro nuclear reactor

Poland’s Grupa Azoty Police said on Wednesday that it has signed a deal for the development and construction of a nuclear power research facility equipped with a micro modular reactor (MMR) with Seattle-based Ultra Safe Nuclear Corporation (USNC) and the Polish West Pomeranian University of Technology, said the company.

USNC said the 30MWt MMR would be a fourth-generation high-temperature, gas-cooled “nuclear battery”. State-controlled chemical and fertilizer producer Azoty Police, a member of largest Polish chemical group Grupa Azoty, said: “The reactor will serve as a training, research and testing facility. Cellulose films – Chemical recycling

It will be connected to the energy infrastructure of Grupa Azoty Police, which will provide a unique opportunity to study, test, optimize and integrate the MMR zero-emission energy source with an industrial facility.

“Cooperation in this area will allow the development of a plan for the full-scale implementation of the use of nuclear energy for chemical processes and the generation of steam and hydrogen at the facilities of Grupa Azoty Police. “This will be another significant step towards the decarbonisation of the Grupa Azoty Group’s technological processes.”

The agreement for the micro reactor was concluded in relation to a US-Polish cooperation in MMR development, formally established by an intergovernmental agreement in February 2021. Cellulose films – Chemical recycling