ChemicalRecycling PETBottle Bioaromatics 14-04-2021 - Arhive

ChemicalRecycling PETBottle Bioaromatics

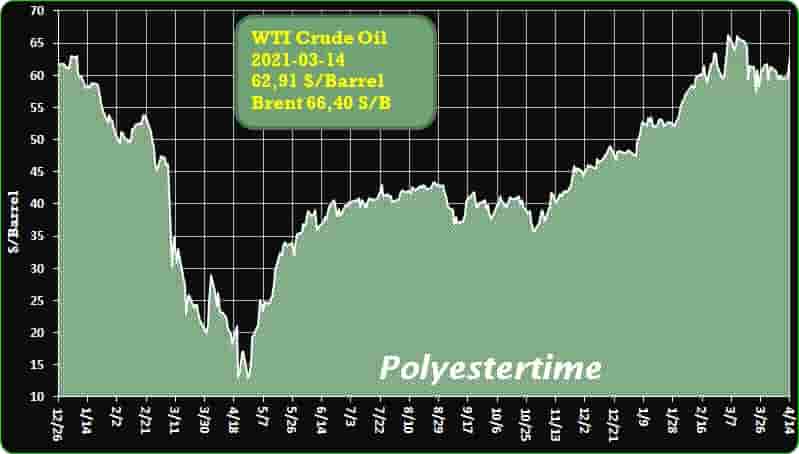

Crude Oil Prices Trend

-Supercritical Steam Process Can Convert All Plastic Waste to Virgin Materials

Mura Technology’s HydroPRS process creates raw ingredients for infinitely recyclable new virgin-grade products from all types of plastic.

U.K.’s Mura Technology is pioneering a globally scalable solution to recycle all forms of plastic waste into virgin-grade plastic, reduce CO2 emissions and feed a sustainable “circular” plastics economy in the next decade. ReNew Elp is currently constructing the world’s first commercial-scale plant in Teeside, U.K., backed by global partners and the U.K. government. The plant is expected to be operational by 2022.

Mura’s proprietaty HydroPRS utilizes the Catalytic Hydrothermal Reactor (Cat-HTR), a technology developed and owned by Licella Holdings Ltd., which breaks down plastics using water in the form of supercritical steam (water at elevated pressure and temperature). The steam acts like molecular scissors, cutting longer-chain hydrocarbon bonds in plastics to produce the valuable chemicals and oils from which the plastic was originally made. This, in as little as 25 minutes. Using supercritical steam means the technology is also inherently scalable. Unlike other methods, which heat waste from the outside, the steam imparts energy from the inside, providing far more efficient conversion of plastic waste; a process which can be maintained regardless of scale.

-Masterbatch manufacturer expands Chinese site

Masterbatch maker Colloids Plastic (Suzhou) has secured an additional 4,000 sq m factory next to its current site in Changshu Economic and technological development zone, and will increase its annual capacity to 18,000 tonnes a year.

Headed up by general manager Dr Craig MacDougall, Colloids China has experienced strong growth in recent years, which has enabled this expansion.The new facility enables Colloids to expand its operation quickly and provides a platform for growth across the Asia Pacific region, said MacDougall. ChemicalRecycling PETBottle Bioaromatics

-Chinaplas 2021, new RadiciGroup products on display

The first trade fair after months of pandemic. China, a market of great interest to the Group in its aim to grow in the automotive, home appliance and consumer goods sectors ChemicalRecycling PETBottle Bioaromatics

RadiciGroup High Performance Polymers – the Group business area engaged in the manufacture and sale of high performance engineering polymers – will be participating in Chinaplas 2021 trade fair, to be held from 13 to 16 April at the Shenzhen Convention & Exhibition Center.

Chinaplas marks RadiciGroup’s return to the world of trade fairs after months of pandemic, during which no business events could be organized. Together with High Performance Polymers, the Group’s Specialty Chemicals Business Area will also be present at the event (Hall 17, Booth G145), exhibiting its wide offering of polyamide 6, 6.6, 6.10, 6.12 polymers and recycled polymers.

“There is a lot of excitement surrounding this event,” Alberto Sessolo, country manager China of RadiciGroup High Performance Polymers, said. “as it is the first Chinaplas where Chinese nationals will make up nearly all the visitors. For us, it is an opportunity to meet with customers, strengthen existing partnerships and discuss future projects,” Sessolo continued. “Since April 2020, the Chinese market has experienced a strong recovery in both internal demand and export. As per tradition, we will be focusing mainly on automotive and its e‑mobility evolution, while also keeping a close eye on the home appliance and consumer goods sectors, where volumes have seen a steady increase.”

-Total Corbion PLA at Chinaplas: PLA Bioplastics for a Brighter Future

Gorinchem, the Netherlands – Total Corbion PLA will be exhibiting at the Chinaplas trade fair from 13th – 16th April in Shenzhen, China.

On display will be a number of partner applications based on Luminy® PLA (Poly Lactic Acid) resins from Total Corbion PLA.

The Luminy® PLA portfolio includes both high heat and standard PLA grades and is used in a wide range of markets from packaging to durable consumer goods and electronics. ChemicalRecycling PETBottle Bioaromatics

PLA is a biobased and biodegradable polymer made from annually renewable resources, offering a reduced carbon footprint versus many traditional plastics.

Ryan Wang, General Manager China at Total Corbion PLA, will be present to meet and greet interested parties and together with his team looks forward to explaining the advantages of PLA: “The demand for Luminy® PLA in China is very strong.

Chinese consumers are motivated to contribute towards a more sustainable, circular society and Luminy® PLA, offering a reduced carbon footprint and compostability plays an important role in achieving these goals.”

-EU and US still replenishing China’ s textile and apparel

Since Q3 2020, China’s textile and apparel trade has shown a recovery growth and a steady recovery. In Q4, with severe pandemic outside China, many mills shut down. At the same time, due to the period of replenishment in overseas market, Wal-Mart replenished stocks largely, and many overseas orders flew back to China. The epidemic outside China spread, which has created a great bonus period for China local cotton textile industry to some extent.

Combined with many favorable factors such as the domestic e-commerce Festival, the cotton textile industry started bull market at the end of November, which lasted for several months. Both production and marketing of mills throve, and they were fully engaged. ChemicalRecycling PETBottle Bioaromatics

However, in mid-March 2021, the market gradually weakened, and fresh orders of mills greatly reduced. So, is the cycle of overseas consumption improvement and inventory replenishment over? Do overseas orders have continuity?

-Covestro presents innovative polycarbonate solutions at CHINAPLAS 2021

At the CHINAPLAS 2021 trade fair to be held in Shenzhen, China from April 13–16, Covestro will showcase a range of cutting-edge technologies and innovative solutions in various fields, as well as insights into design and aesthetics, all under the motto “Pioneering a circular future together”. This is another proof of Covestro’s commitment to building a Circular Economy and a sustainable future.

Meanwhile, the materials manufacturer unveiled plans to start offering the world’s first climate-neutral polycarbonates later this year, in a major step towards its vision to become fully circular while better supporting its customers to reach their sustainability goals. ChemicalRecycling PETBottle Bioaromatics

Covestro presents innovative polycarbonate solutions at CHINAPLAS 2021

“Pioneering a circular future together”

- Launching the world’s first climate-neutral polycarbonate

- Advanced solutions designed to boost the Circular Economy

- Design aesthetic creating value for customers

-Swiss Clariant opens new process and light stabilisers facility in China

Clariant has opened a new joint venture facility for process and light stabilisers at Cangzhou in Hebei, China, the Swiss specialty chemicals maker said on Monday.

The facility is jointly owned by Clariant and Beijing Tiangang Auxiliary Co (Tiangang), a privately owned producer and supplier of light stabilizers in China, it said in a statement. ChemicalRecycling PETBottle Bioaromatics

Process and light stabilizers are types of additives used to reduce degradation of plastics which is particularly caused by exposure to light, heat and air.

The new facility is located within the Cangzhou National Coastal-Port Economy & Technology Development Zone.

Details on plant capacity and investments were not disclosed

-2021 to be critical for European textiles and clothing sector: Euratex

2021 will be a critical year for the European textile and clothing sector, according to the European Apparel and Textile Confederation (Euratex). On the occasion of releasing its quarterly economic update, Euratex is concerned that the COVID-19 crisis may be followed by disruptions in the global supply chains, affecting the competitiveness of the industry. ChemicalRecycling PETBottle Bioaromatics

Economic data up to December 2020 reflect a dramatic contraction in demand and production of textile and clothing items, caused by the COVID-19 pandemic. Over the full year 2020, the EU turnover fell by – 9.3 per cent in textiles and by -17.7 per cent in clothing, compared with 2019. The crisis was particularly felt in the middle of the year (with production losses over 50 per cent). Towards the last quarter of 2020, business activity recovered in the textile industry (+1.6 per cent as compared with the previous quarter), while it further deteriorated in the clothing sector (-6.8 per cent), as a result of the decline in consumption expenditure and the slowdown in non- essential activities, according to Euratex.

Looking at trade performance, T&C (Textile and Clothing) extra-EU exports slipped back by -13.6 per cent in 2020. The majority of EU top-10 customers experienced a steep decline in 2020. EU imports increased by +5.5 per cent in 2020.

-Canada Supports Innovation For Compostable Bioplastic

The Government of Canada continues to encourage alternatives to plastic waste. We are dedicated to creating jobs and driving innovation by investing in climate solutions.

Joël Lightbound, Parliamentary Secretary to the Minister of Public Safety and Emergency Preparedness and Member of Parliament for Louis-Hébert, on behalf of Canada’s Minister of Natural Resources, the Honourable Seamus O’Regan Jr., today announced a $1-million investment to BOSK Bioproducts Inc. as part of the second phase of the Bioplastics Challenge. This challenge is aimed at helping small businesses reduce pollution by turning forest-based residue into sustainable plastic materials. ChemicalRecycling PETBottle Bioaromatics

With this funding, BOSK Bioproducts Inc. will focus on the installation of a small-scale production line for proto-typing the formulations of compostable bioplastics made from forest biomass, developed at National Research Council Canada. Additionally, it will allow for product formulation and better compatibility with existing industry manufacturing equipment.

As part of the first phase, BOSK Bioproducts Inc. developed a highly compostable and cost-effective new bioplastic made from paper mill sludge and wood fibre residue that could be used in areas like 3D printing, food packaging, plastic bottles and containers for cosmetics.

-NOVA targets ’22 start-up of Canada cracker, PE project

NOVA Chemicals has surpassed 65% completion for its second Advanced SCLAIRTECH technology (AST) polyethylene (PE) unit and the third phase of its Corunna cracker expansion project, the company said on Monday.

The first of eight of electrical substations was safely energised in March, and the company estimates that both units will commence full start-up activities in late 2022 after the Corunna site turnaround, which is targeted for spring 2022, NOVA said.

The new AST PE unit, located at the new Rokeby site in St Clair township, Ontario, will have a capacity of 1bn lb/year ( 454,000 tonnes/year). The cracker expansion will provide ethylene feedstock to the new AST facility, expanding the existing unit’s current capacity by more than 50%. ChemicalRecycling PETBottle Bioaromatics

ChemicalRecycling PETBottle Bioaromatics