ChemicalRecycling PETBottle Biopolymers 13-04-2021 - Arhive

ChemicalRecycling PETBottle Biopolymers

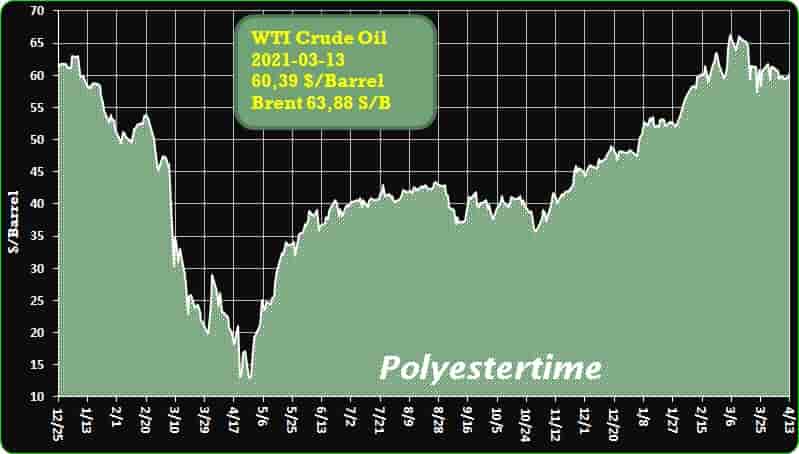

Crude Oil Prices Trend

-Carbios and Equipolymers partners in PET recycling

The Clermont-based company Carbios, a pioneer in the enzymatic recycling of plastic and textile polymers, has signed an agreement with Equipolymers which should host, at its site in Schkopau (Germany), a unit that will produce 40,000 tonnes of recycled PET each year, said Axelera.

In March, Carbios and Equipolymers, a subsidiary of Equate Petrochemical, signed a “ non-exclusive and non-binding agreement in the form of a Letter of Intent ”. If confirmed, Equipolymers, “ European leader in PET production ”, will host a unit at its Schkopau (Germany) site that will produce 40,000 tonnes of recycled PET each year using the enzymatic process developed by Carbios.

This agreement also provides for ” assistance in securing the sources of supply of PET waste for this unit ” which will enable Carbios to ” transform the plastics industry market and take full advantage of its global leadership in this industry “. In addition, it will consolidate its model: the concession of operating licenses for its technologies and know-how and the sale of enzymes to its licensees who will build their own production units for recycled PET.

-Commodity shortage, China PA66 rose again in March

According to SunSirs data, the national PA66 market continued to be active in March and spot prices for various brands continued to rise. As of April 1, the average offer price of pa66 medium viscosity injection molding sample companies was approximately RMB42,900/ton, an increase of 17.53% over the average start-of-month price and 96.34% compared to the same period last year The price position broke through the all-time high. ChemicalRecycling PETBottle Biopolymers

The pattern of contraction in the supply of products upstream of PA66 continued and the loss of capacity of crude oil and chemical companies affected by the COLD DISASTER in the United States recovered slowly. The volume of domestic imports of adiponitrile and hexadeamine continued to be low and producers remained high. At present, the supply of goods on the market is low and there are no clear signs of an improvement in the model. The higher spot price is mainly high.

The upstream price position was high and the pa66’s domestic price continued to rise in March. The range of the spot offer is between about 44,000 RMB/ton and 44,500 RMB/ton and the listing has exceeded an all-time high. The shortage of raw materials meant that polymerization companies did not receive enough raw materials for production. At the moment, there is a general shortage of raw materials in national PA66 polymerization plants and the overall operating rate in the sector has fallen to about half. Pingdingshan Shenma, Huafeng Group and other domestic PA66 manufacturers continue the non-listing strategy to the outside world and have no pressure on inventory, mainly by providing contract customers. Inventory in the hands of retailers fell further and the deal was unbalanced towards a high ratio and reluctant to sell.

-Huhtamaki Fiber Alabuga will build a production of biodegradable packaging in the UAE “Alabuga”

LLC “Huhtamaki Fiber Alabuga” intends to launch the production of environmentally friendly and biodegradable packaging for eggs from paper fiber and produce 130 million packages per year, the UAE “Alabuga” said.

The founders of the project are “Partner Polarkap Oi” from Finland and “Huhtamaki Finance BV” from the Netherlands. The production facilities should cover an area of ??6 hectares. The plant is slated to open in the first quarter of 2021. The volume of investments will amount to 1.4 billion rubles, 35 jobs are to be created.

In February this year, Finnish Huhtamaki Flexible Packaging Europe received approval from the European industry group RecyClass (Belgium) for its three new laminated polyethylene tube technologies, developed in collaboration with Czech company Zalesi and toolmaker Plastuni Lisses, part of the Somater Group. Pipes made with this technology from HDPE with easy to apply direct printing have been tested in an independent laboratory. The first PBL 220/11 HD technology, developed in collaboration with Zalesi, enables the production of fully recyclable HDPE products. In fact, the resulting recycled plastic has been tested in the production of new HDPE bottles at concentrations up to 25%. ChemicalRecycling PETBottle Biopolymers

-Commodity price rises, support for PC costs is strong in China

According to data monitored by SunSirs, as of April 6, the total pc market price was RMB27,800.00/ton. The price of the PC market continued to move to a high level and the price continued to rise. Compared to the same period this month, the price increased by 5.84%, up to 1,600 RMB/ton. ChemicalRecycling PETBottle Biopolymers

The internal pc market fluctuated and increased, the price continued to be high, the bisphenol raw material a market still went up, the cost of the PC was a certain support, the price continued to rise, the general atmosphere of market transactions was cautious, the industry kept a cautious wait-and-see attitude, seemed reluctant to sell psychology , the PC market is expected to still maintain the upward trend in the coming week, manufacturers passively support the price, difficult to have a downward trend.

The price of bisphenol upstream continued to rise and there was still an expectation of an upward trend. The reference price was 27,800-28,000 RMB/ton, stock remained low and the supply side was limited. bisphenol A was 265.69, up 5.52 points from the previous day, a record high in the cycle, up 268.55% from the lowest point of 72.09 on April 6, 2020 .

-Saudi Sabic, SIRC collaborates on chemical recycling

Sabic, a key Saudi-based petrochemical producer, has agreed with Saudi Investment Recycling Company (SIRC) to establish a chemical recycling project in Saudi Arabia.

The agreement signed at Sabic’s headquarters in Riyadh also proposed a feasibility study on the construction of a chemical recycling plant in the country to convert plastic waste into pyrolysis oil. The initiative is in line with Sabic’s long-term vision of recycling plastics to achieve a circular economy.

The collaboration is set to help fulfil the country’s waste management objectives that are aligned with Saudi Arabia’s Vision 2030 and reinforces Saudi G20 Presidency’s commitment to the Circular Carbon Economy, said Yousef Al-Benyan, SABIC vice-chairman and CEO. ChemicalRecycling PETBottle Biopolymers

-EPA hears divergent opinions on chemical recycling

If a process breaks down scrap plastics into chemicals that are later used to make new plastic, should the federal government consider that “recycling?” What if the end product is a fuel that is combusted?

Those are just a couple of the plastics-related questions the U.S. EPA is grappling with as it seeks to define exactly what “recycling rate” will mean. Last fall, the agency released a national recycling rate goal of 50% by 2030. Using current methodologies, the EPA estimates the U.S. has a 32% recycling rate.

But the EPA is considering changing the calculation methodology. In particular, the agency is examining which sources of material, types of materials, management pathways and destinations to count. Not surprisingly, among the 108 comments from different recycling industry stakeholders, advice differed dramatically.

One of several points of contention is whether EPA should consider chemical recycling technologies as “recycling.” ChemicalRecycling PETBottle Biopolymers

-Pakistani Engro plans construction of propane dehydrogenation unit and PP production

Pakistani company Engro Corp will spend USD31.4 million on design, engineering and technical studies for the proposed propane dehydrogenation unit and polypropylene (PP) production, the company said.

“This is in continuation to our letter to the PSX dated April 26, 2019, in relation to the company’s intent to explore investment opportunities in the petrochemical sector and the approval by the Board of Directors of the company (the “Board”) for commencement of a study in relation to a polypropylene facility based on propane dehydrogenation (“PDH-PP Project”),” the company said in a statement to the bourse. ChemicalRecycling PETBottle Biopolymers

Engro said that its Board in its meeting held on April 8th, 2021, has approved an amount of up to USD 31,400,000 towards conducting engineering, design and technical studies including a Front End Engineering Design (FEED) study in relation to the PDH-PP Project.

“The results of these studies, when completed, are expected to inform the final investment decision in relation to this project, which decision will also be based on a conducive policy environment and arranging the right mix of debt and equity partners at such time,” the company added.

Over the last years, the plastics value chain has been calling for the establishment of an appropriate European legislative framework on the use of recycled plastics in food contact applications. The joint

aim of our industries is to facilitate the circularity of plastics packaging while ensuring the health of EU citizens, by setting an appropriate testing and control systems. Promoting the use of recycled plastics ChemicalRecycling PETBottle Biopolymers

in food contact applications is also in line with the Commission’s new Circular Economy Action Plan that aims to accelerate the transition to a circular economy.

Since 1993, the PET value chain has made substantial progress in closing the PET packaging loop and continues to promote recycling to not only meet, but also exceed, the Commission’s mandate of

achieving 25% recycled content in all beverage containers by 2025. Many of our members have recently announced their intention to go beyond existing EU targets and use much higher amounts of

recycled content in their beverage containers. Regrettably, regulatory inaction is threatening the food contact value chain and the ability to truly close the loop and shift to a circular economy.

The European Food Safety Authority (EFSA) has been requested to provide Scientific Opinions on the safety evaluation of the mechanical recycling process to produce recycled PET intended to be used for

manufacture of materials and articles in contact with food (in accordance with Commission Regulation (EC) N° 282/2008).

-Bio vegetable packaging made with plastic recovered from the sea

Agromediterránea has launched a new container for the marketing of BIO radishes under its brand Sun & Vegs. It is a sustainable container made with recycled plastic that has been recovered from areas near the coasts and in the seas of Southeast Asia. ChemicalRecycling PETBottle Biopolymers

It is doing so as one of the main partners of Prevented Ocean Plastic, which in 2020 alone prevented more than 830 million plastic bottles from polluting the sea.

The BIO radishes are marketed in a 100% R-PET container, designed with a minimum micron size, which can be recycled for reuse. In addition to innovating with the material used, Agromediterránea has picked a format that had so far never been used for radishes: a 200-gram cup with a lid – instead of the usual bag or flowpack – which keeps the product fresh for longer and facilitates its consumption.

“We continue to innovate to always find the best ways to bring our products directly from the field to our customers. We are constantly testing various alternatives and we are able to offer a wide range of more sustainable options adapted to current consumer demands,” says Jesús Gómez, general director of Agromediterránea.

-Emporio Armani Inspired By Water For Its Sustainable Line

Finding its common ground between sustainability, Emporio Armani continues its commitment to conscious fashion practices for Spring/Summer 2021.

Channeling the spirit of noble sailors, the campaign visuals explore the relationship between body, nature, and water depicting its free-flowing aesthetic. With the combination of advanced textile research and practical design, the brand finds common ground between sustainability and functionality. Embracing the marine aesthetic with a blue and white color palette, contrasting stitching, and offset silhouettes collection, it features an array of lightweight garments, the menswear offering includes a selection of anoraks, blousons, and Bermuda shorts with the womenswear consisting of light dusters, cargo pants, and mini tops.

Constructed from GREENLON and NEWLIFE, these technical fabrics are made in Italy using nylon and post-consumer polyester derived from plastic bottles. Conveying a passion for the sea, the crinkled nylon repurposes recycled plastic waste including fishing nets and lint from synthetic carpets whilst the organic cotton employs no GMO and grown without pesticides. ChemicalRecycling PETBottle Biopolymers

ChemicalRecycling PETBottle Biopolymers