Chemicals BiobasedPolymers CarbonFiber 12-03-2021 - Arhive

Chemicals BiobasedPolymers CarbonFiber

Crude Oil Prices Trend

-MEGlobal raises ACP for April 2021 by USD140 per tonne

MEGlobal has announced its Asian Contract Price (ACP) for monoethylene glycol (MEG) to be shipped in April 2021, according to the company’s press release.

Thus, on 10 March, the company said ACP for MEG would be at USD930/MT CFR Asian main ports for arrival in April 2021, up by USD140/MT from the previous month.

The April 2021 ACP reflects the short term supply/demand situation in the Asian market.

As MRC reported earlier, MEGlobal announced its March ACP for MEG at USD790/MT CFR Asian main ports, up by USD50/tonne from February 2021.

MEG is one of the main feedstocks for the production of polyethylene terephthalate (PET).

-R&D/Leverage Europe produces PET round bottle for Robinson Packaging

R&D/Leverage Europe were contacted by Robinson Packaging for the supply of a full ISBM solution to produce a 500ml PET round bottle for the “My Fabulosa” range.

Although this product did not appear technically difficult to produce with regards to processing, more times than not, round containers can provide you with technical problems when it comes to producing acceptable products.

They are more susceptible to poor material distribution and lensing compared to oval bottles. Chemicals BiobasedPolymers CarbonFiber

So from the very start R&D/Leverage’s challenge was to provide a complete product solution that would best nullify these common problems and assisted with this project from product design, tool manufacture and tooling approval onsite.

“The level of professionalism, service and reliability provided by R&D/Leverage played a major part in helping us to bring this project in not only on time, but ahead of schedule, with the tool producing acceptable parts from the very first trial.”

-Pregis responds to e-commerce boom

Driven by growing demand for e-commerce, Pregis has announced two new facilities in Wisconsin, USA. Chemicals BiobasedPolymers CarbonFiber

Production has been moved to a new film converting plant in Elkhorn from a nearby location in East Troy, doubling the number of converting lines. The facility converts multilayer coextruded PE film (which has been blown at its Sussex, Wisconsin facility) into pre-opened bags supplied on a roll or in a box.

The bags are used with Sharp Packaging bagging equipment at fulfilment centres to package and ship a variety of soft goods, pharma/nutraceuticals and other non-fragile products.

To support the increased demand for equipment, Pregis is also moving its equipment assembly operations from the current Sussex, Wisconsin facility to a new location in Germantown, Wisconsin in the second quarter. This move enables more efficient assembly layout, double the production space to support current and future growth, and allows additional space for further expansion of its poly converting capacity at the current Sussex facility.

-Joint venture delivers ‘Made in India’ biopolymer compounds

Local production of biodegradable, partially bio-based plastics has started in the Indian state of Maharashtra as a result of a joint venture (JV) between FKuR Kunststoff and India’s SKYi Innovations. Chemicals BiobasedPolymers CarbonFiber

The two firms established SKYi FKuR Biopolymers in 2019 and have now begun producing the Bio-Flex product range for local demand as well as for distribution to neighbouring regions. This, the companies claim, makes the JV the first dedicated manufacturer of compostable biopolymer compounds in India.

Bio-Flex is a family of flexible bioplastics for a wide range of processing methods. They are fully biodegradable or compostable (according to EN 13432) and are based entirely or partly on natural raw materials. Main applications are flexible films, including agricultural, household and hygiene, as well as thermoformed and injection moulded products.

-ALPLA UK to focus on regional PET recyclate

ALPLA UK, a subsidiary of the ALPLA Group, a leading plastic packaging company, will henceforth be cooperating with the British waste management company Biffa. With this collaboration, ALPLA will increase the proportion of British recyclate used in the United Kingdom to manufacture packaging for home care products.

From May 2021, ALPLA UK will source food-grade polyethylene terephthalate (rPET) plastic pellets from the Biffa recycling plant in Seaham, County Durham. The recyclate will be used for the manufacture of home care packaging. As such, the amount of recycled plastic used in day-to-day household products such as washing-up liquid and cleaning product bottles will increase. Chemicals BiobasedPolymers CarbonFiber

The partnership will promote a local circular economy for plastics in the United Kingdom. The collection and recycling of plastic waste help conserve natural resources and protect the environment.

-Conductive Carbon-Fiber Thermoplastics Edge Aluminum in Structural Applications

BASF’s new electrically conductive grades of carbon-fiber-reinforced polyphthalamide can replace heavier aluminum and magnesium without a loss in stiffness or strength.

BASF is expanding its polyphthalamide (PPA) portfolio of Ultramid Advanced with carbon-fiber-reinforced grades with fillings of 20, 30, and 40%. These electrically conductive grades can replace heavier aluminum and magnesium without a loss in stiffness or strength. Chemicals BiobasedPolymers CarbonFiber

The new grades combine these properties with the advantages of Ultramid Advanced N (PA9T) — dimensional stability, chemical and hydrolysis resistance, and high strength and modulus — which makes them unique among carbon-fiber-reinforced PPAs already available in the market. The new carbon-fiber (CF) reinforced grades can be used to manufacture automotive structural parts for body, chassis, and powertrain; pumps, fans, gears, and compressors in industrial applications; and stable and ultra-lightweight components in consumer electronics. With this offering, BASF complements its PPA portfolio of more than 50 grades already available on the market.

-AST/Lindner launch technical centre for recycling HDPE

European manufacturer of plastic containers, drums and bottles, AST, has set a long-term target to increase the amount of recyclates used in its products and aims to supply its own raw materials. For this reason, AST is investing in a new centre of competence with a complete plastics recycling line to process post-industrial and post-consumer HDPE (high density polyethylene). As a project partner, it is relying on a system solution from Lindner. Chemicals BiobasedPolymers CarbonFiber

Since 1977, AST Kunststoffverarbeitung GmbH has been producing packaging with approval for dangerous goods in Erndtebrück, Germany. Today, the company is a European market leader when it comes to plastic containers for chemical products or food, and it is working hard to increase the sustainability of its products by using recyclables.

-SMI: Towards a greener packaging

There will be more than 300 billion extra pieces on the shelves of large supermarket chains by 2024 – This is what emerges from the predictive analysis carried out by Mecs-Centro Studi Ucima on the growth prospects of packaging machinery. The market survey highlights that the most dynamic sectors will be those related to the production of soft drinks, dairy and confectionery and, as regards the packaging, those related to recyclable plastics. Chemicals BiobasedPolymers CarbonFiber

The research is a confirmation of the fact that the great worldwide debate concerning sustainability of packaging solutions has become a key factor in the growth strategies of food and beverage manufacturers.

Environmental sustainability and innovation go hand in hand

Environmental protection is a primary objective, that can be achieved only through the joint action of companies and consumers. Companies are increasingly introducing technical innovations in order to produce in an environmentally friendly manner, while consumers are adopting lifestyles and behaviors capable of preserving the environment and enabling the collection and recycling of empty packaging.

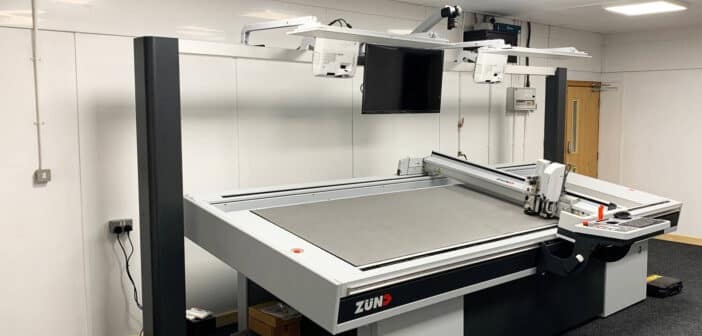

-CASE STUDY: The Tuning Shop purchases its first Zünd digital cutter

Established in Cornwall in 2008, The Tuning Shop is a small family-run business specializing in automotive interior products such as gear/handbrake gaiters, seatbelt pads, armrest covers and gear knobs made from natural leather, Alcantara, suede and other materials. Chemicals BiobasedPolymers CarbonFiber

The company was founded by Gregor Radzik, a self-proclaimed petrolhead who always wanted to work within the automotive industry. Having started his company with the support of his wife from their home 12 years ago, the business has now evolved into a dedicated production site in Cornwall that employs 10 people.

“Originally we started as a reseller of interior products. Then we decided that to move the business forward and be able to meet customer expectations, we needed to start manufacturing these products ourselves,” explains Radzik. “This led to the decision to invest in our business with a range of industrial sewing machines, embroidery machines and 3D printers. Over the years this allowed us to extend our range of products and offer bespoke, customized, one-off projects too.“

Baerlocher expands Indian plant for Ca-based stabilisers

German additives maker Baerlocher is expanding its production site in Dewas in the Indian state of Madhya Pradesh. The new production facility will have a capacity of 30,000 tonnes/year and will exclusively produce Ca-based PVC stabilisers. Early last year, the 4th Plant of the Baerlocher production site in Dewas went on stream, part of an expansion programme for the production site in India. The US$30 million investment was announced in February 2019 with the goal of doubling the production capacity as well as a new technical service and product development laboratory.

The new production facility at Dewas for polymer additives represents an additional manufacturing plant dedicated entirely to producing calcium-based PVC stabilisers. The new facility will be built on the newly acquired 25-acres of land adjacent to its current facility. Chemicals BiobasedPolymers CarbonFiber

Chemicals BiobasedPolymers CarbonFiber