Chemicals BiobasedPolymers CO2Polymers 13-03-2021 - Arhive

Chemicals BiobasedPolymers CO2Polymers

-SIPA and PTI enter into strategic partnership

Sipa and PTI reached an agreement to join forces on the market, with PTI now becoming part of the Sipa group. This strategic partnership will help both companies to increase their visibility and create new business opportunities.

“Joining forces with SIPA makes perfect sense for PTI. We bring extensive knowledge in package development and material expertise to their capabilities’ portfolio,” said Thierry Fabozzi, PTI CEO. “This strong collaboration will also give PTI access to SIPA’s latest equipment and enable us to provide even better turnkey solutions for our brand-owner customers.”

“We are very pleased to see PTI become a part of the Sipa group. In addition to the technical synergies, we also see geographic advantages.

-Chinese researchers develop ‘display textiles’

Chinese researchers have integrated the fabrication of display devices with the fabric weaving process, taking wearable technology a step further.

Made of smart electronic fabric, the “display textiles” can function similar to a display through which people can browse information, send and receive messages.

The textiles weave conductive weft and luminescent warp fibers to form micrometer-scale electroluminescent units at the weft–warp contact points.

During scientific polar expeditions or geological explorations, a tap on the soft clothing will display the location information in real time, and mapped navigation can be guided by it. Chemicals BiobasedPolymers CO2Polymers

People with speech difficulties can communicate and express themselves efficiently and conveniently with clothing made of the textiles.

The display textiles are flexible and breathable and withstands repeated machine-washing, making it suitable for practical applications, said Professor Peng Huisheng from Fudan University, who led the research team.

This fabric is expected to promote rapid integration and development of traditional textile manufacturing and Internet of Things, human-computer interaction, big data and artificial intelligence, said Peng.

-Clariant and India Glycols tap into green renewables megatrend by forming joint venture

JV to become a leading supplier of renewable ethylene oxide (EO) derivatives

Production facilities in India to supply local and global markets

Both parties contribute parts of their existing businesses and Clariant makes relevant equalization payment to attain majority ownership Chemicals BiobasedPolymers CO2Polymers

Clariant, a focused, sustainable and innovative specialty chemical company, and India Glycols Limited (IGL), a leading company in the manufacturing of green technology-based chemicals, today announced a strategic partnership to establish a 51-49% joint venture in renewable ethylene oxide (EO) derivatives.

By combining production and distribution capacity, the joint venture is expected to become a leading supplier of renewable materials to the rapidly growing consumer care market in India and neighboring countries, while providing Clariant the ability to leverage the EO derivatives globally across the home care, personal care and industrial applications segments of its Industrial and Consumer Specialties business.

-Shortage fuelled switch from virgin to recycled polyolefins could prove permanent for some grades

Severe shortages of virgin polyolefins are driving substitution to recycled polyolefin alternatives. With ongoing regulatory and consumer pressure against single use plastics, for some grades there may not be a swich back.

Europe recycled polyolefin pellet values are once again at their most competitive levels against virgin on record across all grades, as virgin price rises continue to outpace those in the recycled polyolefins chain. Chemicals BiobasedPolymers CO2Polymers

This is despite recycled polypropylene (R-PP) currently being at record high levels, and prices for recycled polyolefin pellets having risen by up to 55% since the start of 2021. ICIS records date back to November 2019 for R-PP, and to May 2019 for recycled polyethylene (R-PE).

-Treasury predicts 40% jump in recycled plastic use

The use of recycled plastic in packaging will jump by an estimated 40% once the plastics packaging tax has been introduced in April 2022, the Treasury has predicted.

The considerable boom in the recycled content of plastic packaging was forecast by the Treasury in a policy paper published last week in relation to Budget 2021.

It said legislation will be introduced in the Finance Bill 2021 to establish the tax, which will be set at £200 a tonne for packaging with less than 30% recycled content.

Predicting what would be a substantial increase in the use of recycled plastic in packaging, the Treasury document stated: “The rationale of this tax aims to increase the use of recycled content in plastic packaging and it is estimated that as a result of the tax the use of recycled plastic in packaging could increase by around an estimated 40%. This is equal to carbon savings of nearly 200,000 tonnes in 2022 to 2023, based on current carbon factors.” Chemicals BiobasedPolymers CO2Polymers

China’s petrochemical markets surged again in February on continuous tight supply and recovering post-holiday demand, further fuelled by US outages as a result of a cold wave. Chemicals BiobasedPolymers CO2Polymers

The ICIS China Price Index rose 22% to 1331.59 on 26 February compared with the end of January. Out of 17 components comprising the index, n-butanol, acrylate esters and 2-EH topped the list with over 50% growth month on month.

The restocking-driven price increase continued after a short break for the Chinese Lunar New Year holiday, as the government called for travel curbs to control the spread of the COVID-19 pandemic.

With tight supply amid concerns about fierce global shortages, the market went up quickly after the holiday.

China future’s markets reacted actively toward the changes upon post-holiday reopening, with increased expectations of global inflation also boosting spot markets.

According to market sources, China’s shortage of chemical supplies will continue for a while, with reduced imports amid worldwide scarce availability.

-Toyo Ink and Itochu partnership targets multilayer packaging

The companies say they will open a recycling pilot plant in Japan this year.

Toyo Ink SC Holdings Co. Ltd., the Tokyo-based parent company of the specialty chemicals manufacturing conglomerate Toyo Ink Group, and Itochu Corp., a global trading house headquartered in Toyko, say they have entered into a cooperative agreement that targets the recovery and reuse of multilayer film packaging materials. Chemicals BiobasedPolymers CO2Polymers

The companies seek to achieve a plastic recycling rate of more than 40 percent in Japan and abroad, an increase from Japan’s current rate of 27 percent.

In 2019, Toyo Ink, in cooperation with a leading environmental solutions provider, developed a plastic recovery technology for multilayered flexible packaging, where a deinking coating agent and a delaminating adhesive are applied to the plastic film surrounding the ink layers. After use, the packaging material is subjected to an alkaline treatment in which the coating agent, adhesive and interlaying ink layers are cleanly released from the film substrate, according to the company. This results in the recovery of high-quality plastic material that can then be reused to create new products. A pilot plant based on this plastic recovery process is being built in Japan and is set to become operational later this year.

“We are excited by the opportunities our new online event platform provides to deliver you the same high-quality content, expert speakers and unique networking opportunities you have come to expect; all of which will now be available to access remotely from your home or office,” says organiser Smithers.

“GOCarbonFibre is a unique, high quality conference with high calibre speakers,” adds Dow Chemical. Chemicals BiobasedPolymers CO2Polymers

As the only conference focused 100% on carbon fibre, GOCarbonFibre provide a unique global forum for carbon fibre manufacturers, composite industry executives, technologists and new entrants to receive a comprehensive update on the outlook for growth, supply and demand and recycling of carbon fibres.

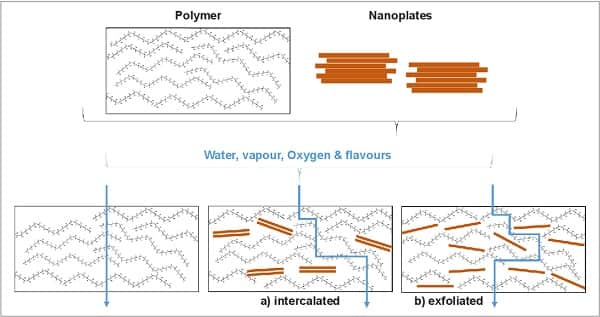

-Polymer nanocomposites – additives, properties, applications, environmental aspects

Various additives are added to plastics to either improve processability, change product properties or protect them against thermal, UV or light influences. In the case of a polymer nanocomposite, the additives have at least one dimension of less than 100 nm and can be found in the form of platelets, fibres or particles.

They primarily serve to improve tensile strength, thermoformability, flame retardancy, optical and electrical properties, and the barrier properties of the plastic into which they are incorporated. Chemicals BiobasedPolymers CO2Polymers

Nanoadditives include layered silicates such as montmorillonite, carbon-based additives (e.g. carbon black, carbon nanotubes, graphene), nanoscale metal oxides (e.g. SiO2, TiO2, Al2O3), metals (e.g. nano-silver, -gold, -copper), or organic additives such as nanocellulose or lignin nanoparticles.

In addition to reductions in resources and weight, nanoadditives also have the potential to replace harmful substances such as environmentally problematic halogenated flame retardants. Across the world, polymer nanocomposites are already being used in packaging materials, the automotive industry and transportation, aerospace and energy technology, as well as in sporting goods.

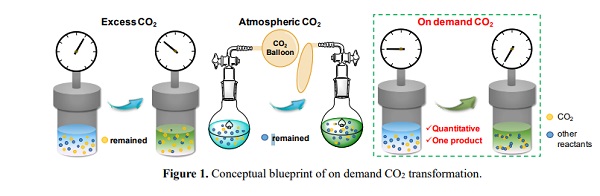

Chemical conversion of CO2 offers a promising avenue to valorize the waste “greenhouse” gas and deviate the reliance of chemical synthesis on fossil fuel feedstocks, thus creating a more sustainable carbon economy.1,2 However, the common high pressure reaction condition results in low CO2 conversion, leading to either the discharge of trouble[1]some CO2 to the atmosphere, or the cumbersome energy input CO2 recycle. Chemicals BiobasedPolymers CO2Polymers

To date, only few reactions can theoretically consume CO2 in quantitative yield, such as catalytically irrelevant mineral carbonation3 and amines to absorb CO2 and generate carbamate.4 But quantitative CO2 transformation is scarcely reported in sophisticated CO2 catalysis such as various CO2 reduction reactions to afford fuels and bulk chemicals,5,6 and non-redox coupling reactions for cyclic carbonate and polymer production.7-9 The product yield or the conversion of economically valuable reactants is at the center of these research fields while CO2 conversion is neglected and hardly studied on a mole basis.

In this context, we are wondering whether CO2 could be quantitatively consumed in these advanced CO2 chemical transformations.

Chemicals BiobasedPolymers CO2Polymers