Chemicals BiobasedPolymers Composites 15-03-2021 - Arhive

Chemicals BiobasedPolymers Composites

Petrochemicals Naphtha PETRecycling Spandex Trend

Crude Oil Prices Trend

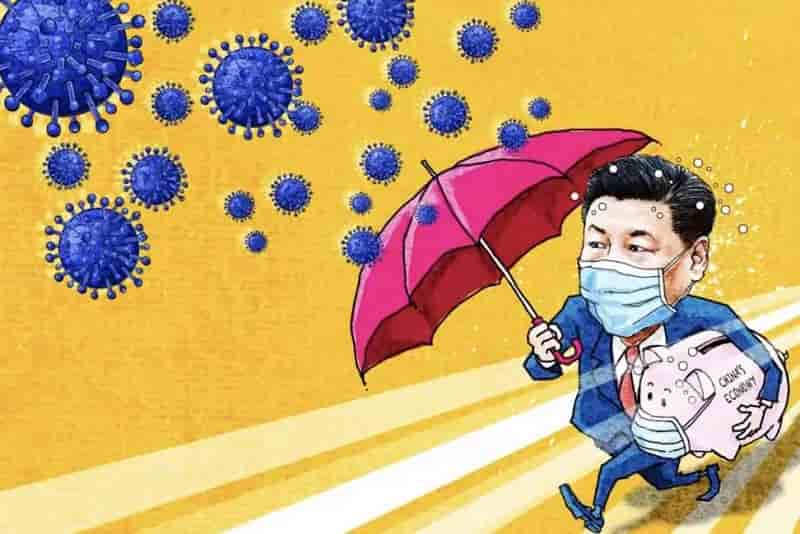

Global Times: China’s economy has shed the clouds of the coronavirus and picked up its recovery in the first two months of 2021, with key economic indicators improving at a sizable growth rate of more than 30 percent, thanks to last year’s low base and a steady acceleration of manufacturing fired up by domestic and overseas demand.

Analysts say the rosy January-February economic performances signal that China may record a GDP growth rate of between 15-20 percent for the first three months, which would make its first-quarter economy expansion the highest among major global economies.

China’s economy came to a sudden standstill in the first three months last year amid a strict lockdown to stifle the virus, but it quickly rebounded after the government led the whole country to launch an impressive fight against the epidemic and put it under control in 2020. China’s economy grew 2.3 percent year-on-year.

-Current recycled polymer price competitiveness fuelling switch away from virgin material

European prices across the three largest recycled polymer chains are at their most competitive level against virgin since at least December 2018, and at their most competitive level on record for multiple grades of pellet material.

This follows a price spike in virgin material, which recycled polymer values have not kept pace with. This is despite recycled polypropylene (R-PP) currently being at record high levels, and prices for recycled polymers having risen by up to 55% since the start of 2021. Chemicals BiobasedPolymers Composites

The relative competitiveness of recycled polymer values is fuelling substitution away from virgin. With sustainability targets mounting and a continued backlash against single-use plastics from regulators and consumers, there has been talk that for some material grades the switch could be permanent.

The three major market for recycled polymers are recycled polyethylene terephthalate (R-PET), recycled polyethylene (R-PE) and recycled polypropylene (R-PP). ICIS records date back to June 2006 for R-PET, May 2019 for R-PE, and to November 2019 for R-PP.

-Shell Pennsylvania petchems project 70% complete, operational in 2022: spokesman

Previously projected to start up in first half of 2021

Complex includes three polyethylene plants with total capacity of 1.6 million mt/year

Shell Chemical’s $6 billion petrochemical complex in Pennsylvania is now more than 70% complete and projected to be operational sometime in 2022, a company spokesman said March 12. Chemicals BiobasedPolymers Composites

“On a daily basis workers are commissioning major pieces of equipment within our infrastructure units – a phased process that will continue until start-up” said the spokesman, Curtis Smith, in an email. “That includes connecting pipes and wiring that will eventually loop and extend for hundreds of miles along the site’s 386 acres,” he said.

The petchems complex in Monaca, northwest of Pittsburgh, is expected to be completed in 2022, Shell CEO Ben Van Beurden said in February. Previously, Shell projected the startup in the first half of 2021 after suspending work in mid-March 2020 due to coronavirus pandemic concerns.

The project is one of the largest construction sites in North America and includes a 1.6 million mt/year cracker and three polyethylene plants with a combined capacity of 1.6 million mt/year, according to Shell.

-Turbulence unsettles European polymer markets

But steel and paper is also struggling

Turbulence on Europe’s polymer markets is hitting plastics processors in the region with full force, reports Plastics Information Europe (PIE). Sufficient quantities of granulate are unavailable and prices have risen significantly since the beginning of the year, with some approaching all-time highs.

According to PIE, production bottlenecks for plastics and their intermediate products have in some cases cut the quantity available by up to half of the amount normally on the market. In Europe, polymer producers are currently dealing with 13 cases of force majeure, 11 system malfunctions, 22 slowdowns and 24 maintenance shutdowns.Chemicals BiobasedPolymers Composites

At the same time, plastics goods producers face significantly lower imports from Asia, the Middle East and the US. Resin prices in the Far East have outpaced those in Europe for several months, which has redirected much of the global flow of raw plastics from Europe to Asia.

The combination of reduced supply and increasing demand is boosting prices for plastics granulate at an unprecedented rate. Depending on type, materials currently cost 20-50 per cent more than at the beginning of 2021, explains PIE.

-Parallel Paths to Reducing Plastic Waste in the Environment

The Alliance to End Plastic Waste welcomes new member companies and calls for project proposals that capture economic value from plastic waste.

The Alliance to End Plastic Waste, an international non-profit organization, welcomed five new members to its membership ranks: Amcor plc, Atlantic Packaging Co., Inter Pipeline Ltd., Kirin Holdings, and Novacel. These additions bring to 57 the number of member companies in the alliance.Chemicals BiobasedPolymers Composites

“The momentum we are seeing in our membership points to a growing number of companies directing their attention to the actions they can take in ending plastic waste in the environment,” said Jacob Duer, President and CEO of the alliance. “With five new members, we welcome even more diversity into the alliance from both a membership category and geographic standpoints. We are excited to include new viewpoints and different expertise on our membership bench.”

-UK-EU automotive, chemicals trade hit hard in January as Brexit deal kicks in

Prior stockpiling and new Brexit trade regulations caused a fall of 40.7% in UK exports to the EU in January, month on month, as the country ended its membership of the 27-nation bloc’s single market, the Office for National Statistics (ONS) said on Friday.

The petrochemicals-intensive automotive sector was hit hard, said the ONS, along with other chemicals-based sectors.

UK GDP during January fell 2.9%, less than analysts had expected, after the UK implemented on 5 January lockdown measures to stop the spread of a new coronavirus variant, shutting most retail venues and keeping most residents confined to their homes. Chemicals BiobasedPolymers Composites

TRADE SHARPLY DOWN

Alongside the sharp fall in UK exports to the EU, imports from the bloc into the UK fell 28.8%.

-Turkmenistan PP export trade prices break another record

1,500 tonnes of Turkmenbashi refinery polypropylene (PP) were sold in a single day of export trades at the State Commodity and Raw Materials Stock Exchange of Turkmenistan with pricesbreaking another record, according to ICIS-MRC Price report.

According to the bidders, 1,500 tonnes of Turkmenbashi refinery’s PP raffia grade were put up for export sale at the State Commodity and Raw Materials Exchange of Turkmenistan on 10 March. Chemicals BiobasedPolymers Composites

The starting price was set at $1,515/tonne free on board/free carrier (FOB/FCA). PP prices climbed during the trades to reach a record $1,775/tonne FOB/FCA, the total volume of PP was sold in one day.

Deals were done with shipment within six months.

-Recycled and bio-plastics: a solution to the PaxEx plastics footprint?

The passenger experience industry often considers plastics in aesthetic terms, from developing exciting new shapes, patterns and technologies to avoiding the ‘wall of beige’ in aircraft cabins, and everything in between. But as more and more of the plastics in other areas of our lives see developments around reducing their environmental footprint via using recycled plastics and bioplastics, what are the prospects for the cabin? Chemicals BiobasedPolymers Composites

The answer is complicated. For a start, these aren’t single-use plastics, and despite their presence right in front of passengers’ noses, they’re not enormous by volume.

“While we do use some thermoplastics in our products for the aircraft cabin, the actual real estate taken up by thermoplastics is quite small,” Collins Aerospace spokesperson Joel Girdner explains to Runway Girl Network.

“When we do use them, they are meant to last 20+ years and can be serviced. So they’re not considered the Fast Moving Consumer Goods (FMCG) most people associate with plastics and the immediate impact those have on say, landfill scenarios.”

-GKN AEROSPACE AND PARTNERS LAUNCH ASCEND TO ACCELERATE HIGH VOLUME COMPOSITE TECHNOLOGIES

- £39.6M ASCEND consortium to develop and accelerate high volume composite technologies

- Public-private investment and cross-sector collaboration across UK industry aims to create more than 700 UK roles by 2035

- Consortium strengthens UK industry’s position at forefront of next generation of sustainable aircraft and future mobility technology

GKN Aerospace is leading a new UK industry consortium called ASCEND (Aerospace and Automotive Supply Chain Enabled Development) to develop and accelerate composite material and process technologies for the next generation of energy efficient aircraft and future mobility. Chemicals BiobasedPolymers Composites

The £40m consortium, funded by a £20.0M commitment from industry and a £19.6M commitment from the UK Government via ATI, will focus on greater adoption of composite technologies today, the industrialization of new technologies, as well as accelerating aerospace production rates to meet future high-volume requirements. The collaboration will help develop technologies from across the UK supply-chain to develop the advanced materials and automation equipment required to manufacture lightweight structures for the sustainable air mobility, aerospace and automotive industry.

The shredder-extruder combination from recycling technology provider PURE LOOP is the ideal solution for recycling challenging production waste. This category includes drip tapes and irrigation pipes that accumulate as waste during the production of irrigation systems or are rejected during quality inspection. Manufacturers who already implement this technology reuse production waste in the form of recycled pellets in proportions of up to 20 percent – without any loss of quality compared to production from virgin material. Chemicals BiobasedPolymers Composites

“This level of reuse can still be significantly increased thanks to the high quality of the recycled pellets,” says Manfred Dobersberger, Managing Director of PURE LOOP. “The high demands on the recycling process result from the high volume of the bulky input material as well as the material composition of the drip tapes and irrigation pipes,” he explains. Their job is to ensure that crops can grow and thrive, using as little water, fertiliser and pesticides as possible. For this purpose, either thin-walled HDPE drip tapes laid on the surface or HDPE irrigation pipes buried in the ground are used. The water is distributed through emitters. In the case of the thin-walled drip tapes (150 – 250 µm), these are LLDPE injection-moulded parts which are spaced at regular intervals of around 20 cm. In the case of thick-walled irrigation tubes (over 300 µm), the emitters are also fitted with a silicone membrane for pressure compensation, so that the same flow rate of water is discharged from each emitter over the entire length of the tube and the flow of water is not obstructed by soil, sand or roots growing into the emitter.

Chemicals BiobasedPolymers Composites