Chemicals BiobasedPolymers Masterbatches 10-03-2021 - Arhive

Chemicals BiobasedPolymers Masterbatches

Crude Oil Prices Trend

-Recycler files for Chapter 11 bankruptcy protection

PET recycler CarbonLite and its subsidiary PinnPack Packaging have filed for Chapter 11 bankruptcy protection.

Production at all three of US-based CarbonLite’s facilities – in California, Texas and Pennsylvania – and its Californian thermoforming business PinnPack Packaging, will continue as usual without interruption, as will payment of all employees. Layoffs are not under consideration. There will be no stoppage of supply to CarbonLite’s customers during the reorganisation period.

Pressures directly related to the coronavirus pandemic contributed to CarbonLite’s decision to reorganise. This included temporary production slow-downs caused by employee illness, the low price of virgin plastics relative to recycled PET, and a nine-month delay in the opening of the company’s new Pennsylvania facility caused by travel restrictions that held up equipment commissioning by European manufacturers.

-Recycling: Old plastic, new perspectives

From information and design all the way to protection and portability: plastic packaging fulfills a variety of functions that have become integral to the modern lifestyle. Chemicals BiobasedPolymers Masterbatches

Plastic waste, however, constitutes a challenge for the environment and the global climate. Henkel has therefore committed to using plastic responsibly within a circular economy.

In countries like Germany and Norway, the life cycle of a polyethylene (PET) bottle begins and ends at the supermarket, where consumers return it after use. Unlike in many other countries, the bottle is not incinerated or spilled out into the ocean: it is collected by a reverse vending machine. Reusable bottles are simply cleaned and refilled.

Reinach, Switzerland, 9 March 2021 – Archroma, a global leader in specialty chemicals towards sustainable solutions, today announced that it has become a The BHive® partner to help foster chemical compliance and management across the textile supply chain. Chemicals BiobasedPolymers Masterbatches

The BHive® is an innovative digital chemical management platform that provides at-a-glance information about chemical products to its users. It was developed by GoBlu International Ltd. to allow manufacturing facilities to easily create digital inventories of the chemical products used onsite using a smartphone. They can identify in a matter of seconds which products meet sustainability requirements of their brand and retail customers, who they can share this information with as well. This enables brands and retailers to achieve full transparency about the chemical use in their global supply chain. Now, over 30 international fashion brands and 500 factories are partnered with The BHive® to drive sustainable chemistry in the textile and fashion industry.

-Chemical recycling of plastics is scaling quickly, say CEOs

The chemical recycling of plastics, also known as molecular or advanced recycling, is scaling quickly, according to Chemweek with reference to Bob Patel, CEO of LyondellBasell, and Jim Fitterling, chairman and CEO of Dow.

The two spoke last Tuesday at the CERAWeek 2021 by IHS Markit virtual conference.

Chemical recycling does not require the degree of sorting required by mechanical recycling, noted Patel, and it yields virgin resin completely identical to resins produced from traditional petrochemical feedstocks. “With molecular recycling, you can take mixed plastic waste, convert it back to feedstock, and then put it back in the front end of the cracker (to make olefins) and then polyethylene (PE) or polypropylene (PP),” he said. Chemicals BiobasedPolymers Masterbatches

Patel said chemical recycling has the additional advantage of much larger scale than mechanical recycling. “I think we’re probably three to five years way from being at the scale that our industry is used to,” he said. “I think it has to be some form of pyrolysis, and then it’s a matter of how do you scale that up and manage any sort of environmental impacts from the pyrolysis process itself.”

-Why lyocell hard to jump like other fibers?

Prices of most fibers rose sharply in the first two months of 2021 and many products saw the growth of more than 30%, while lyocell fiber just edged up by around 6%, whose increase was even less than that of dissolving pulp. In other words, by the end of Feb, although the price of lyocell fiber had been higher than that at the end of 2020, the profit decreased notably. Chemicals BiobasedPolymers Masterbatches

As the raw material of chemical fiber, lyocell fiber is even known as the green fiber of the 21st century due to its excellent performance and clean production process. Why the performance in the first two months of 2021 is not as good as that of most fibers?

Let us look at why most other fibers can rise sharply. Jan-Feb is generally the slack season of textile industry and China’s Lunar New Year holiday is during that period when demand is hard to burst. In addition, the increase during the period is mainly concentrated in fiber, while end-user products rising slowly is obviously not the driving force, so it is hard to say that the rise in fiber price is boosted by demand.

-Mitsui to sell nonwovens business in China

Japanese chemicals firm Mitsui Chemicals is to transfer its 100% ownership of Mitsui Chemicals Nonwovens (Tianjin) Co., Ltd. (MCNT), a Chinese subsidiary for the production and sales of nonwovens, to Foshan Nanhai Beautiful Nonwoven Co., Ltd (BTF). Chemicals BiobasedPolymers Masterbatches

This share transfer will see the Mitsui Chemicals Group concentrate its resources on two bases in Japan and Thailand. In doing so, it adds that it will look to further bolster its presence in the sanitary nonwovens markets of Japan and the ASEAN region.

-Milliken acquires masterbatches producer in Germany

Milliken (Spartanburg, South Carolina) says it has acquired Zebra-chem (Bad Bentheim, Germany), a producer of peroxide masterbatches and blowing-agent masterbatches, reported Chemweek. Chemicals BiobasedPolymers Masterbatches

Financial terms of the deal have not been disclosed.

Zebra-chem produces masterbatches for polyvinyl chloride (PVC), polyolefins, and engineering plastics. Typical products are organic peroxide masterbatches, molybdenum disulfide masterbatches, and blowing-agent masterbatches, according to Milliken.

Peroxide masterbatches, such as those made by Zebra-chem and Milliken, make it possible to incorporate up to 100% recycled content in plastics, Milliken says. “Milliken’s long-term focus on innovation and sustainability encourages us to consider how we contribute to some of today’s leading challenges, like how to effectively incorporate recycled plastics in manufacturing,” says Halsey Cook, Milliken president and CEO.

-ITMA Asia + CITME open for online visitor registration

Shanghai – Online visitor registration for ITMA Asia + CITME 2020, which will be held at the National Exhibition and Convention Centre (NECC) in Shanghai from 12-16 June, is now open. Chemicals BiobasedPolymers Masterbatches

Visitors who purchase their badge at www.itmaasia.com and www.citme.com.cn will enjoy special online rates. Early-bird rates available till 6 June are RMB 60 for a five-day badge and RMB 30 for a one-day badge. Standard onsite rates cost RMB 100 for a five-day badge and RMB 50 for a one-day badge. Visitors who register online will be also given access to the exhibition e-catalogue.

The show owners and organisers said they are committed to working closely with the authorities, such as the Joint Prevention and Control Mechanism of the State Council and the Shanghai Convention and Exhibition Industries Association (SCEIA), to implement preventive and social distancing measures to enable the combined exhibition to be held safely.

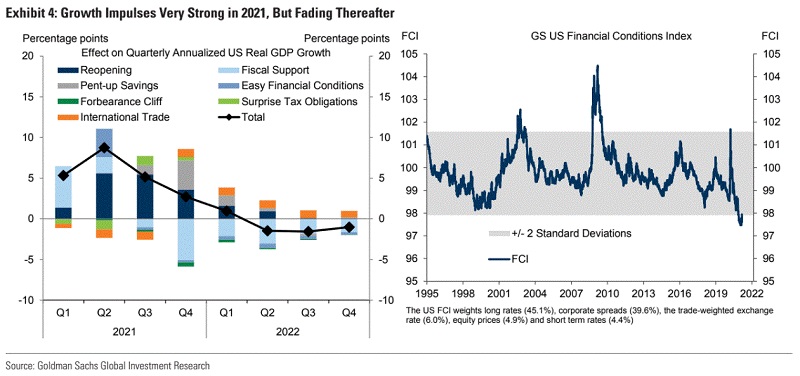

-After the US boom comes the US bust! (or does it?)

The US economy is entering a rude boom. It has tailwinds from monetary and fiscal policy, vaccine policy and catch-up growth plus, in due course, renewed investment into shale oil. So much we already know. Chemicals BiobasedPolymers Masterbatches

But, before long, it will also turn on its head, via Goldman:

- Senate passage of the nearly $1.9trn American Rescue Plan Act (ARP) marks a big political victory for President Biden and will give another jolt to an economy that is already accelerating.

- …hospitalizations and deaths continue to decline. While some of this improvement probably reflects lags, another reason is that the most vulnerable populations in advanced economies such as the US and UK are now largely protected.

- All this good news continues to put upward pressure on government bond yields, with negative spillovers to risk asset markets in recent weeks. At the longer end of the curve, we still see significant upside for both nominal and real yields.

- Once tapering does start, our baseline remains that it will be another two years before the funds rate starts to rise. First, the suggestion in the December FOMCminutes that the tapering process will resemble 2013-2014 probably means steps of$10-15bn per meeting, which alone would take a year or more. Second, pushing core PCE inflation above 2% on a sustained basis will likely require a very tight labor market, in part because policy factors are likely to weigh on health care service costs(a whopping 20% of the index).

-Impacts of re-opening of trades between Pakistan and India on Indian cotton yarn

Pakistan may allow local textile mills to import Indian cotton yarn

Recently, Pakistan media released news that peak season of consumption and transfer of orders intensified tight supply of cotton yarn. The surge of raw materials increased production costs of downstream textile mills, and apparel exporters also concerned that they could not delivery overseas orders on time.

Participants along textile industrial line exerted pressure on Pakistan government continuously and required permission to import Indian cotton yarn in order to ease the tightness of cotton yarn supply. APCPLA even put forward requirement for the government to guarantee free duty on imported cotton yarn. Abdul Razak Dawood, former Minister of Commerce of Pakistan and current government commercial adviser, said on social media that the Premier worried about the shortage and rise of cotton yarn price and indicated to take necessary measures including cross-border trades of cotton yarn to keep value-added export. Chemicals BiobasedPolymers Masterbatches

Chemicals BiobasedPolymers Masterbatches

Chemicals Biotechnology NylonRecycling 09-03-2021