Chemicals Biodegradable Polyamide BOPET 27-02-2020 - Arhive

Chemicals Biodegradable Polyamide BOPET

-Invista declares force majeure for the Nylon 66 / PA66

Invista declares force majeure for Nylon 66 / PA66 for the plant located in Kingston, Ontario.

Invista has been forced to declare force majeure for the PA66 plant located in Kingston, Ontario, Canada due to problems receiving railcar shipments of feed stock that are needed to make polymer.

The disruption in rail service in Canada is being caused by Indigenous anti pipeline protesters/activists in support of the Wet’suwet’en First Nation in British Columbia who are fighting a 416-mile gas pipeline crossing through the Tyendinaga Hohawk territory.

The protesters in Ontario have blocked rail service since Feb. 10th, which has been blamed for 1,400 layoffs at Canada’s main rail companies, and disrupted feed stock and chemical shipments in and around Ontario.

In early February Canadian National, which owns the rail line, won an injunction to clear the blockade near the city of Belleville, Ontario. Chemicals Biodegradable Polyamide BOPET

Unfortunately, the police are wary of protests and violent confrontations like in the 1990s with Indigenous groups, so thus far the authorities have been unwilling to forcefully remove the protesters/activists from the tracks.

Crude Oil Prices Trend

-TAIF GC to continue to implement biopolymer production project

The Tatarstan company believes that the licensor’s problems shouldn’t influence the end result

TAIF GC’s licensor — Italian bioplastic manufacturer Bio-On S.p.A. — announced bankruptcy after the court’s decision late last year. Regardless of the Italian company’s further fate, 2BIO JSC, which was created by TAIF JSC together with Milan-based InvestiRE Italia società a responsabilità limitata, continued the elaboration of the basic project of bioplastic production. As Realnoe Vremya found out, Italian authorities took the solution of the licensor’s problems under control.

-Serbia, India, Pakistan and European Bioplastics

Michael Stephen, an international spokesperson from the plastics industry, shares his thoughts and opinion on important issues impacting the bioplastics industry. Today, Michael writes about Serbia, India, Pakistan, Printweek, Re-inventing the Wheel and European Bioplastics.Chemicals Biodegradable Polyamide BOPET

Serbia

I was reading an article “Plastic bags must be regulated by comprehensive law” on 21st February about a conference in Belgrade. It seems that everyone agreed that Serbia has to regulate the issue of plastic bags in a systematic way, and that producers are rightly complaining of uncertainty in policy.

-Bickford’s installs flexible PET line for sensitive drinks and CSD

Bickford’s, a family-owned and treasured Australian brand, put their trust in Sidel for the very first time, and installed a complete, flexible PET line, handling both sensitive beverages and carbonated soft drinks (CSD).

Riding the wave of healthy living, it was not only able to expand their portfolio but also to improve production efficiency and sustainability.Chemicals Biodegradable Polyamide BOPET

All in all, this significantly optimised their total cost of ownership (TCO), while relying on new bottle designs.

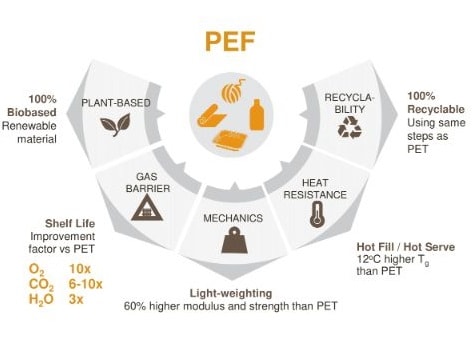

We may love our pet, but do we love fossil-based PET? Don’t worry, PEF is working on kicking PET out of the plastics space. PEF is one of the most interesting plant-based polymers right now and Avantium is looking to PEF for the future of packaging. Their market traction in high-value applications like multilayer packaging, enhanced bottles and optical film are nothing to scoff at.Chemicals Biodegradable Polyamide BOPET

How are they doing it? What can we learn from them? What’s their next step in commercializing renewable polymers? What’s the latest engineer studies for the 5 Kiloton Flagship Plant? A detailed timeline path to commercialization and answers to these questions and more.

-China site for Calysta’s commercial scale-up

THE first commercial scale plant for Calysta’s single cell protein fish feed is to be built in China.Chemicals Biodegradable Polyamide BOPET

The factory, with an eventual capacity of 100,000 tonnes, will produce the novel ingredient FeedKind, which is made by fermenting natural gas.

The development is the result of a joint venture between FeedKind manufacturer Calysta and feed additives company Adisseo.

-P&G Launches New Line of Antibacterial Cleaning Products, Microban 24

Don’t worry about continuously reapplying this new antibacterial cleaner. Microban 24 keeps surfaces protected for 24 hours1.Chemicals Biodegradable Polyamide BOPET

oday, P&G announced the launch of Microban 24, a new brand of antibacterial home sanitizing products that keeps surfaces protected against bacteria for 24 hours when used as directed.

Not only does Microban 24 kill 99.9% of bacteria on contact, but it also keeps working throughout the day. Microban 24 provides a protective shield that keeps killing bacteria for a full 24 hours, even when the surface is touched or contacted multiple times.

-UFlex Gears up To Reduce Delhi-NCR Plastic Waste

Of the 8.3 billion metric tons of plastic that has been produced in the world, a recent study states that a whopping 6.3 billion metric tons has become plastic waste either lying in the landfill or swimming in the ocean. A meagre 9% of this plastic waste gets recycled. Reports indicate that by 2050, there will be 12 billion metric tons of plastic on this planet, if there isn’t an eco-system built to recycle plastic waste.Chemicals Biodegradable Polyamide BOPET

UFlex, a pioneer in Multilayer Plastic Manufacturing and Waste recycling, is scaling up its recycling strength to help build a circular economy, by the way of setting up two lines that will wash and recycle post-consumer waste and subsequently give a second life to plastics.

-Investors chase sustainable aromatics

Processes using lignin, sugar, plastic waste, and more are moving out of the lab

udo Diels, a research leader at the Belgian science institute Vito, gives a hopeful smile when asked if aromatic molecules—which make up about 40% of all industrial chemicals produced today—could soon be made from waste biomaterials or plastic.

Several years ago there was widespread talk that the arrival of such sustainable aromatics was imminent, but little—if any—commercial activity materialized. This time, though, Diels, who chairs the advisory board of Shared Research Center Biorizon, a Dutch research center that is striving to commercialize bioaromatics, is confident bioaromatics will soon be developed. “It’s our ambition to be on the market in 2025, and we are on schedule,” Diels says.Chemicals Biodegradable Polyamide BOPET

-Switching to plant-based plastics

In 2017, industrial ecologist, Roland Geyer, led a study on the ‘Production, use and fate of all plastics ever made’ and estimated that there are more than 8.3 billion metric tons (Mt) of plastics that have been produced since the 1950s.

The study also found that in 2015, only nine percent of plastics have been recycled, 12 percent incinerated and 79 percent accumulated in landfills or the ocean.

If this trend continues, it is expected that roughly 12,000 Mt of plastic waste will be in landfills or the natural environment by 2050.Chemicals Biodegradable Polyamide BOPET

It is undeniable that plastic waste contributes to the earth’s ecological devastation and issues in human health.

-Audi now uses recycled plastic bottles in their seat fabrics

Just about every automaker uses recyclable materials in their cars today. From bumpers, interior bits, and even wiring harnesses, manufacturers are finding ways to build cars greener. Audi, on the other hand, has brought that up to the next level.

Instead of using fabrics and textiles for their seats, the German automaker will be making seat trims out of recycled plastic bottles. Chemicals Biodegradable Polyamide BOPET

It will first be used in the next-generation A3 with other models eventually following suit. So how do they do it?

Chemicals Biodegradable Polyamide BOPET