Chemicals Biotechnology Plasticwaste 08-03-2021 - Arhive

Chemicals Biotechnology Plasticwaste

Petrochemicals Naphtha PETRecycling Polyamide Trend

Crude Oil Prices Trend

-Biffa doubles HDPE recycling capacity

UK-based plastics recycler Biffa is doubling the HDPE recycling capacity at its Washington, Sunderland plant with a £13 million ($18m) investment. This will add a further 14,000 tonnes of recycling output, growing its total annual capacity to 39,000 tonnes – or 1.6 billion HDPE bottles a year. Chemicals Biotechnology Plasticwaste

In addition, the investment will create 50 new jobs in the local area, where the company already employs 115 people at Washington and its £27.5m ($38m) recycling plant at Seaham, which opened last year. Biffa currently also operates an HDPE facility at Redcar which employees a further 140 people.

The expansion is the latest in a series of significant strategic investments made by the group as part of its commitment to building a circular economy. In the last five years Biffa has invested more than £54.5m ($75.4m) in plastics recycling infrastructure with plans to quadruple its plastics recycling capacity by 2030.

-Plans unveiled for ‘world’s largest’ factory for chemical recycling

Biofabrik and Enespa AG have announced plans to build the biggest facility for plastic recycling made of modular pyrolysis plants. Chemicals Biotechnology Plasticwaste

Biofabrik and Enespa AG have unveiled their plan to build the biggest facility for plastic recycling made of modular pyrolysis plants. The first WASTX Plastic unit will begin its operation in the spring and over the next few years the location will gradually be scaled to reach a capacity of several hundred tons per day. And due to stocks and bonds issued by Enespa, everybody can participate, said the company.

“Do something for the future of your kids. Do something for yourself. Invest in plastic recycling,” said Cyrill Hugi, CEO of Swiss-based company Enespa AG. “Everyone knows about the plastic crisis – it’s a general issue of all human beings. The thing is, when it is out of your sight, you forget about it and just don’t care anymore – this is the biggest problem. But it’s still out there. We have to learn how to handle the plastic waste correctly.” He also noted that “surprisingly, even in a country like Switzerland plastic recycling is still startlingly low with incineration rates as high as 80 percent.”

-Enval works with Kraft Heinz and Sonoco to expand use of innovative recycling technology

Enval has launched Touchdown, a joint project with Kraft Heinz and Sonoco aimed at improving packaging sustainability and accelerating the deployment of its novel plastic recycling solution in the United States.

For Enval, the ultimate aim of the project is to see its first recycling plants in the United States. These plants will reportedly be capable of recycling previously unrecyclable plastic packaging using a unique proprietary pyrolysis technology for treating low-density packaging waste. Chemicals Biotechnology Plasticwaste

Enval says that this process is the only technology in the world capable of recycling plastic aluminium laminates by splitting them into high-value oil and aluminium with a low-carbon footprint.

-Government of Canada supports innovative, made-in-Canada solutions to plastic waste

Plastic litter is polluting our rivers, lakes, and oceans, harming the wildlife that call those places home and generating micro and macroplastics in the water we use. Canadians expect the Government of Canada to address plastic waste in their communities. That’s why the Government has a comprehensive plan to achieve zero plastic waste by 2030, including a ban on certain harmful single-use plastics.

Today, the Minister of Environment and Climate Change, the Honourable Jonathan Wilkinson, announced the four winners of the latest Canadian Plastics Innovation Challenges. These small and medium-sized Canadian companies will each receive up to $150,000 toward developing their solutions to address plastic waste.

The following companies are receiving funding to develop their proof of concept:

- Magemi Mining Inc., in Markham, Ontario, is developing a durable recycled paper to serve as a sustainable alternative to plastic packaging like grocery bags.

- CACITH Inc. (Tengiva), in Montréal, Quebec, is creating a network of recyclers to quantify textile waste and find new markets for otherwise wasted materials. Chemicals Biotechnology Plasticwaste

- Met-Tech Inc., in Burlington, Ontario, is developing a low-cost process to recycle more textile waste such as clothing.

- Singular Solutions Inc., in North York, Ontario, is developing a biosustainable additive that will cause plastic textile waste to biodegrade in long-term-composting landfill facilities.

-Match 10 presentation to focus on chemical upcycling of waste plastics

The Mid-Michigan Section of the American Institute of Chemical Engineers (AIChE) will host a special presentation from 11 a.m. to 1 p.m. Tuesday, March 10.

The group is committed to providing a safe and healthy environment for all meeting attendees and will be holding all meetings virtually until further notice. George W. Huber, director of the Center for Upcycling of Waste Plastics and Richard Antoine Professor of chemical engineering at University of Wisconsin-Madison will present “Chemical Upcycling of Waste Plastics.” Chemicals Biotechnology Plasticwaste

New technology is needed to recycle waste plastics and create new plastics that are more biodegradable. This talk will first discuss the recently funded U.S. Department of Energy multi-university center on Chemical Upcycling of Waste Plastics (CUWP). The objective of CUWP is to develop the scientific and engineering principles that will enable the circular upcycling of plastic wastes into virgin plastic resins using chemical technology.

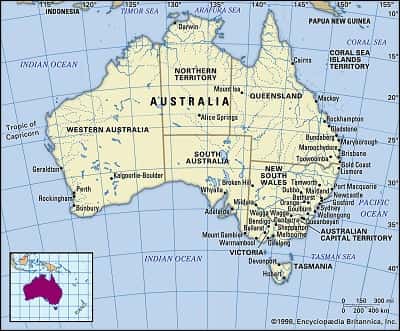

-Australia targets 50% average recycled packaging content by 2025

The Australia National Plastic Plan 2021 has set a recycled content target of 50% by 2025 for all packaging, with separate targets for polyethylene terephthalate (PET), high density polyethylene (HDPE) and polypropylene (PP), as well as phasing out expandable polystyrene (EPS) in certain applications by 2022.

The Plan is the result of Australia’s first ever National Plastics Summit, held in March 2020, and which brought together government, industry and community sectors to identify and showcase new ideas and solutions to tackle the country’s plastics challenge. Chemicals Biotechnology Plasticwaste

-Automotive Suppliers Optimistic Despite Supply-Chain Challenges

In spite of the negative impact of component and raw material shortages, executives at American automotive suppliers reveal continued strength in light-vehicle demand. That is according to the Q1 Original Equipment Suppliers Association (OESA) Supplier Barometer Index (SBI), released March 3, a gauge to measure the sentiments of North American suppliers. Chemicals Biotechnology Plasticwaste

Shortages of certain components and raw materials are impairing suppliers’ ability to fulfill customer volumes, resulting in a drop in the supplier outlook to 62, down from Q4 2020’s SBI of 67. However, that is still 12 points above a neutral level of 50. The Q1 OESA Supplier Barometer focused on production, planning and electrification.

Results indicate that while issues related to the COVID-19 pandemic remain the greatest threat to the industry, these threat ratings continued to ease from the end of 2020. Inventories decreased in 2020, with more than half of all suppliers reporting decreased inventories compared to 2019 as COVID limited production in the first half while demand surged in the second half

-European polymer market struggles with raw material shortages

Shortages of plastics packaging could hit the food sector if the current raw material shortages and significant price increases continue across Europe, claims European Plastics Converters (EuPC). as been under pressure for several months and converters have been reporting difficulties in getting the necessary raw materials to keep their production running, along with alarmingly low stocks. Chemicals Biotechnology Plasticwaste

Demand for polymers had recovered in Europe in the second half of 2020 after a strong drop in production due to the Covid-19 pandemic, and the corresponding lockdown measures. But while plastics converters began to re-increase their production, the supply of raw material did not grow accordingly.

-Elix Polymers and Polyscope Polymers cooperating on specialty materials

Polymer specialists Elix Polymers and Polyscope Polymers have developed a high rubber content ABS to work with Polyscope’s Xiran range of products, for use in the production of sunroof modules. Chemicals Biotechnology Plasticwaste

The high rubber-content Acrylonitrile Butadiene Styrene (ABS) modifier in powder form is used to improve the toughness of engineering thermoplastics. It is also used by several compounding companies due to its high quality and superior impact strength performance at room and low temperature for polymer blends.

The high rubber content ABS is part of the Elix Polymers high-performance polymer modifiers product portfolio which also includes several SAN compounding grades used as base resin for color concentrates.

Chemicals Biotechnology Plasticwaste