Chemicals CrudeOil Polyamide BOPP 29-02-2020 - Arhive

Chemicals CrudeOil Polyamide BOPP

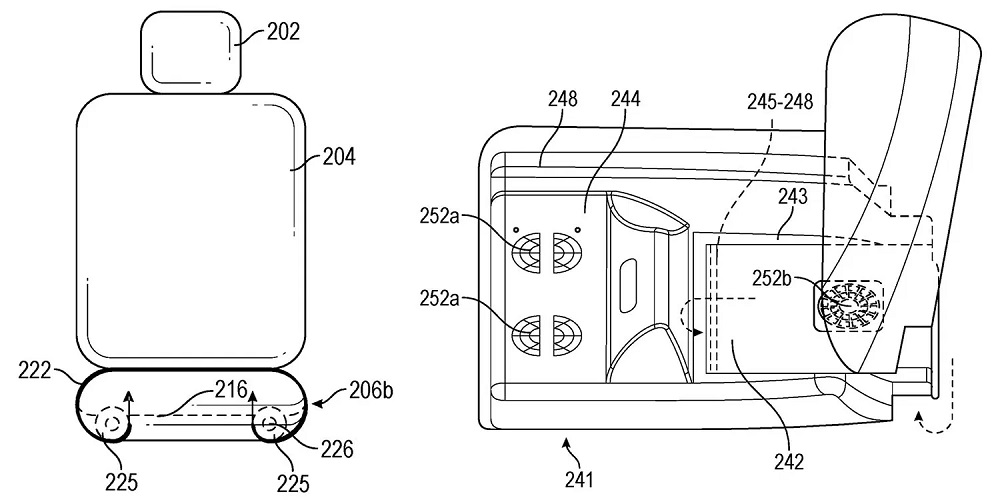

-Apple patent for hi-tech car seat solves a problem created by hi-tech car seat

An Apple patent for a hi-tech car seat describes how the technology could solve a problem created by existing hi-tech car seats …

We may or may not ever see an actual Apple Car, but the company is certainly developing some interesting technology which might someday make it into cars made by other manufacturers. One possibility is a solution to a problem created by the number of different motors in some high-end car seats.

As you adjust the seat to suit you, all these different motors push and pull on the fabric, which is especially problematic with leather, as Apple’s patent explains.

-Anellotech converts Lay’s Potato Chip bag into key feedstock to make plastic bottles.

“This is a world first, a significant step forward for our Plas-TCat technology, solving two major problems at once – expanded rPET supply and efficient, large-scale recycling of single-use packaging (including PE, PP and multilayer films).”

Sustainable technology company Anellotech has announced that a laboratory demonstration of its Plas-TCat technology – which transforms mixed plastic waste directly into chemicals – successfully converted a Lay’s Barbeque Potato Chip (PepsiCo) bag into paraxylene, the primary chemical used to make virgin PET for beverage bottles.

The conversion also had high yields of benzene, toluene and olefins used to make a range of plastics, including polyethylene, polypropylene, nylon, ABS and polycarbonate.

Consumer goods brand owners in the beverage, textile, food and cosmetics sectors are setting ambitious 2025-2030 goals to include recycled PET (rPET) content in their products. Used beverage bottles are the main source of rPET – however, not enough beverage bottles are currently produced, collected or recycled to satisfy growing global demand.Chemicals CrudeOil Polyamide BOPP

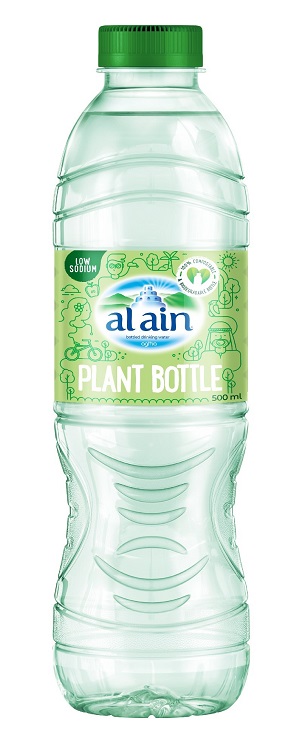

Al Ain Plant Bottle set to be region’s first plant-based water bottle

MoU with Veolia makes Agthia the exclusive FMCG to pilot a recycling program of this caliber in the region Chemicals CrudeOil Polyamide BOPP

Agthia Group PJSC, one of the region’s leading food and beverages companies, announced the launch of Al Ain Plant Bottle, the region’s first plant-based water bottle, at a press conference on the sidelines of Gulfood 2020 during UAE Innovation Month, in the presence of H.E. Dr. Thani Al Zeyoudi, UAE Minister of Climate Change and Environment.

An MoU was also signed between Agthia and Veolia, a global leader in optimized resource management, to launch a PET water bottles collection initiative in the UAE.

-Oerlikon hosts annual technology symposium in India

For more than a decade now, the Manmade Fibers segment of the Swiss Oerlikon Group has been hosting a comprehensive technology symposium at the beginning of each year in the Indian region around Silvassa/Daman. Numerous Indian manmade fiber producers have settled in this area, around a four-hour drive north of Mumbai.

Fed from Oerlikon polycondensation and extrusion systems, these companies manufacture polyester, nylon and polypropylene on large-scale installations with Oerlikon Barmag WINGS POY, WINGS FDY, IDY and DTY product lines and using Oerlikon Neumag’s staple fiber and BCF technologies. Reason enough for the Manmade Fibers segment’s experts to regularly provide their clientèle with detailed specialist presentations in India on the latest developments of the product and service portfolio.Chemicals CrudeOil Polyamide BOPP

-INVISTA MAKES PROGRESS ON SHANGHAI ADIPONITRILE PLANT

Invista (Wichita, Kan.; www.invista.com) has announced its continues progress on a planned 400,000-ton adiponitrile (ADN) plant at the Shanghai Chemical Industry Park (SCIP). This $1.2 billion USD (8.4 billion RMB) investment will help meet the growing demand for nylon 6,6 chemical intermediates in China and the Asia Pacific region. Fluor was recently awarded a contract for EPC work at this site.

In January, the project obtained Environmental Impact Assessment (EIA) approval and Safety Condition Review approval. Detailed engineering and procurement on the project are well underway—with awards already made for more than 90 percent of process equipment. Invista plans to begin construction on the project this year and start production in 2022.Chemicals CrudeOil Polyamide BOPP

-Top Green Heat-Shrink PET Film Gets Thumb’s Up from Association of Plastic Recyclers

Far Eastern New Century’s (FENC) Top Green heat-shrinkable PET film for shrink sleeve labels has been recognized by the Association of Plastic Recyclers (APR) for meeting or exceeding the requirements of APR’s Critical Guidance Protocol for Clear PET Articles with Labels and Closures (PET-CG-02). The announcement was made last week at APR’s annual meeting in Nashville.Chemicals CrudeOil Polyamide BOPP

The heat-shrinkable PET film delivers significantly improved recyclability of post-consumer PET bottles compared with alternative polyester materials such as PETG, according to George Pinter, a partner with Klear Plastic Ventures LLC (KPV), the Ann Arbor, MI–based distributor of FENC’s film in the United States and Canada. The majority of other shrink films currently used for sleeve labels are unable to meet APR guidelines.

-PKN ORLEN licenses Honeywell technology for phenol production

Honeywell has announced that PKN ORLEN plans to use the UOP Q-MaxTM and Phenol 3G technologies to produce 200 000 tpy of phenol at its facility in Plock, Poland. UOP is providing a licence for the technology, in addition to basic engineering design services, plus key equipment, catalysts and adsorbents and technical services.

As part of the project, UOP will provide a cumene unit and a phenol unit with alpha methyl styrene hydrogenation. Chemicals CrudeOil Polyamide BOPP

When completed, the new complex would increase PKN’s market position in high-margin petrochemicals including phenol and acetone.

-New pilot program aims to bring recycling solutions to the pet industry

Three companies establish Flex Forward

Earth Animal, the trusted choice in award-winning, veterinary formulated products, Petfood Experts, a wholesale distributor serving 4500 independently owned retailers and the Pet Sustainability Coalition (PSC), a nonprofit that advances business through environmental and social practices, announces Flex Forward – a 2020 return-to-retail packaging pilot program aimed at reducing landfill waste and delivering sustainable packaging solutions to the pet industry.Chemicals CrudeOil Polyamide BOPP

For Michael Baker, Pet Food Experts CEO, the idea to partner with these organizations was a no-brainer: “With shared values and a commitment to sustainability, the idea to partner with Earth Animal and PSC came naturally. As leaders in sustainability, we owe it to the industry to be a beacon for others to follow on the journey to a more sustainable future.”

-NFY production reboot needs more helpers – Nylon Filament Yarn- Caprolactam China

The first month of Chinese lunar calendar has come to an end, and the weaving industry has ushered in the first wave of labor returning since the COVID-19 was strictly controlled last week (Feb 17-23).

However, new orders were hardly heard and even delivery for previously taken orders was slow. The run rate of nylon textile filament plants slowly lifted from 30% to 41% over the week, as only those who completely shut production gradually recovered operation. There were several reason for the slow reboot of NFY plant production.

- Although the epidemic situation control had been gradually relaxed, it was still difficult for workers to return to work quickly. Migrant workers still needed to be quarantined for 7 or 14 days, which directly affected the production ratio of NFY plants.

- The problems of logistics and auxiliary materials gradually eased, but the recovery of downstream demand was very limited. Near the Lantern Festival, poor logistics and shortage of auxiliary materials were the main reasons leading to the production cut or shut for some filament mills. However, starting last week, these two problems have gradually eased. However, the shortage of workers was the main reason for the slow recovery of production in downstream such as cloth mills and garment factories, which meant that the increase in spinning consumption was limited, which also indirectly affected the enthusiasm of filament mills to increase loads. Chemicals CrudeOil Polyamide BOPP

-PX threatened by epidemic outbreak in China and S. Korea

The COVID-19 is spreading fast in Northeast Asia. Market participants show concerns in the supply of petrochemicals, including PX, from South Korea and Japan.

As is known to all, global PX capacity concentrates in Asia. South Korea and Japan account for over 20% of world’s total.

China, as a major PX consumer, depends greatly on the imports of PX from South Korea and Japan. China received about 8.14 million tons of PX from those two countries, 54% of the total PX imports.Chemicals CrudeOil Polyamide BOPP

Therefore, the plant operations in the two countries, especially in South Korea, would make a big difference to China’s PX supply.

However, we can find from the analysis that the earlier spread of epidemic in China brought impact more on the consumption of PX rather than directly on the plant operating rate. In addition, as moving PX mostly relied on ships, PX movements in China was barely affected.

Chemicals Crude Oil Polyamide BOPP