China-textile-garment-trouble – recycled-rubber 12-07-2022 - Arhive

China-textile-garment-trouble – recycled-rubber

Crude Oil Prices Trend

-Recycling: Finding ways to recycle rubber

In the lead-up to the K trade fair 2022, industry association VDMA provides an interview with Daniela Dingfelder, COO of Deguma-Schuetz GmbH, on the potentials of recycling rubber.

Is rubber sustainable as a material?

Both natural rubber and synthetic rubber have advantages and disadvantages in terms of sustainability. Both are indispensable in everyday life – for everyday goods such as shoe soles as well as in the construction industry, the automotive industry or tunnel construction. The negative aspects are that natural rubber is mainly obtained from monocultures, while synthetic rubber is based on fossil oil. We need rubber, but we want it to be sustainable. That’s why for some time, we’ve occupied ourselves more intensely with recycling. Together with our customers, we are looking for ways to recycle the material and develop the right machines to do so. China-textile-garment-trouble – recycled-rubber

How much interest is there in that area?

Awareness of sustainability has grown enormously within the industry. We can see that in the number of projects that our sector alone is pursuing, as companies recognise their responsibility. At Deguma, we say, yes, we are building machines for rubber production and processing, but we see to it that we do so as sustainably as possible. For example, we have developed a new drive system that enables energy savings of up to 30%. We are also switching to a modular design, so that only components and modules need to be replaced rather than the entire machine.

Deguma is a specialist in retrofitting. Does this also contribute towards climate protection?

Deguma originally comes from the field of machine reworking. We have been working for years on making machines more energy-efficient when they are retrofitted, for example with our new drive system. This enables maximum torques to be achieved even at lowest speeds. One of our customers was able to save 100,000 kWh of electricity per year in production as a result. The machines are extremely durable. We currently have a machine from 1937 under revision. We can bring these machines up to current technical standards and return them to the market, where they can be used for many years to come. They are then very efficient, and raw materials for new machines are saved. But there are limits to what we can do in this field. China-textile-garment-trouble – recycled-rubber

-Towards a circular, plastic-free and regenerative fabrics future

The 10th Future Fabrics Expo, held on the 28th and 29th of June in London, presented an extensive selection of commercially available fabrics to provide alternatives to conventional high environmental impact materials. China-textile-garment-trouble – recycled-rubber

In addition, the expo showcased emerging and speculative fabrics and technologies in the innovation hub and curated area of solutions, which focussed on materials created from agricultural waste and other bio-based ingredients, as well as promoting plastic-free fashion and the integration of biodiversity preservation and regenerative agriculture practices.

The journey to circularity

The fashion industry has to drastically reduce the use of virgin oil-based synthetics such as polyester and nylon and one of the first steps is the adoption of recycled fabrics, as these are generally considered to have a lower environmental impact. While industry is increasingly adopting recycled synthetics, it must be noted that most of these are made from discarded plastic bottles and other plastic waste, rather than pre or post-consumer textile waste.

Environmental organisation and global collaboration network Parley for the Oceans has been one of the success stories in this space and is working with brands including adidas, Dior and Byborre to prevent plastic from entering the oceans and transforming it into sportswear and fashion. More recently, innovators have turned their attention to post consumer tyre waste, which would otherwise be incinerated. Q-Cycle by Fulgar is a yarn created through the chemically recycling of old tyres, which involves breaking down the material into its chemical components and reprocessing it into new materials.

-China’s textile and garment industry is in big trouble

Spotlight on China

Chinese media outlet Da Ji Yuan reported on July 07 that China’s textile and garment industry is suffering from a large number of orders moving out of the country like never before. China-textile-garment-trouble – recycled-rubber

According to the report, China is the world’s largest manufacturer and supplier of textiles and garments. The regime relies heavily on exports of textiles and garments to secure foreign exchange reserves and stable employment.

-China’s textile and garment industry is in big trouble

Chinese media outlet Da Ji Yuan reported on July 07 that China’s textile and garment industry is suffering from a large number of orders moving out of the country like never before. China-textile-garment-trouble – recycled-rubber

According to the report, China is the world’s largest manufacturer and supplier of textiles and garments. The regime relies heavily on exports of textiles and garments to secure foreign exchange reserves and stable employment.

In the first half of 2022, data from the China Chamber of Commerce for Import and Export of Textiles (CCCT) estimated that the scale of China’s textile and garment orders transferred overseas was about 6 billion dollars. Among these, 1 billion came from textiles and 5 billion from garments.

More specifically, India was the main place for textile orders, while Bangladesh, Vietnam, Cambodia, and Indonesia took apparel orders.

An official at CCCT said that the transfer scale would increase to about 10 billion dollars in the second half of this year, 8 billion of which would relate to garment orders and the rest to textiles.

Yue Jin (pseudonym), head of a small textile firm in Wujiang of Jiangsu province said, “This year’s performance is very weak, even more challenging than 2020, and all orders have dropped by at least 40% compared with last year.”

He added that other local small and medium enterprises are also in the same situation. Raw material prices have risen since the beginning of this year but companies have had to keep the same prices for their products to be competitive.

Meng Zhuo, manager of Anhui Garment Import and Export Co., Ltd. said that most factories have no customers’ orders by September this year. At the same time last year, the orders lasted until at least November. And the production of garment factories was too tight to complete all orders then. But this year, factories will have no orders two or three months earlier than expected. China-textile-garment-trouble – recycled-rubber

The China Chamber of Commerce for Import and Export of Textiles has recently conducted a survey where 30% of the surveyees were small and medium enterprises. The result shows that 85% of the companies think that the customers’ orders within the industry will be transferred overseas.

Honeywell announced that Turkish refiner Tüpraş will license Honeywell UOP Ecofining technology to produce biofuels from feedstocks such as used cooking oil and waste animal fat at their refinery in Izmir, Türkiye. The new Ecofining plant is being designed to convert approximately 8,300 barrels per day of waste feeds/feedstocks to SAF, renewable diesel, and other products. China-textile-garment-trouble – recycled-rubber

SAF and renewable diesel have similar molecules to petroleum-based diesel and jet fuels and can be used as a drop-in replacement without engine modifications. In the case of SAF, it can be used in blends of up to 50% with the remainder as conventional (fossil based) jet fuel. Apart from SAF, Bio-naphtha and Bio-LPG are used in the production of plastics, specifically olefins that are building blocks for other chemicals and aromatics used to produce polyester and other packaging materials.

Depending on feedstock choice, renewable diesel and SAF, which are produced from the Ecofining process, are expected to result in a significant reduction in lifecycle greenhouse gas emissions compared to conventional diesel or aviation fuel from petroleum. Honeywell is an early pioneer in SAF production with its Ecofining technology, which has been used to produce SAF commercially since 2016.

-Sharp rise in the price of recyclable materials

Ontario will run out of landfill space at over the next decade.

The value of recyclable materials has jumped in the province year over year. Materials like plastic, cardboard and aluminum have brought in millions to waste management agencies.

Essex-Windsor Solid Waste Authority (EWSWA) recycling revenue more than doubled in 2021. China-textile-garment-trouble – recycled-rubber

The agency that handles solid waste in Windsor-Essex raised nearly $2.8 million more last year than in 2020, thanks to recycling, according to its annual report.

The document explains that prices have increased for the majority of recyclable products. Only the prices of a few, including glass, have not increased, it says.

A ton of polyethylene terephthalate plastic, sometimes used to make plastic bottles, has gone from less than $200 in 2020 to around $900 this year. The price per tonne of newsprint has quadrupled, from $50 in 2019 to $200 in 2022.

According to EWSWA CEO Michelle Bishop, the last time her agency made nearly $5 million in profits was about 10 years ago. I believe it was around 2012. We indeed had a banner year at the time and we received about $4.8 million, she says.

“REVENUE FROM THE PROCESSING, SORTING AND SALE OF THESE MATERIALS HAS INCREASED SIGNIFICANTLY FROM 2020. WE WERE AT $4.9 MILLION FOR 2021. MICHELLE BISHOP, MANAGING DIRECTOR OF EWSWA

The agency is still expecting high prices this year and has already exceeded its forecast, adds Bishop.

She thinks the change in consumer habits during the pandemic has caused the prices of recyclable materials to skyrocket. Since the pandemic, it’s been no secret that many of us are shopping online and getting products delivered right to the door […] This has increased the demand for cardboard , she says.

-Solving the problem of plastic waste

The challenge

Plastic is a fantastic material with many beneficial applications and has become part of our everyday lives. For this reason, forecasts suggest that up to a billion tonnes could be produced every year by 2050. However, just 12% of the plastic that is produced today is recycled. The majority of plastic is either landfilled, incinerated or leaked into the environment, as seen through the rising levels of plastic in our oceans.

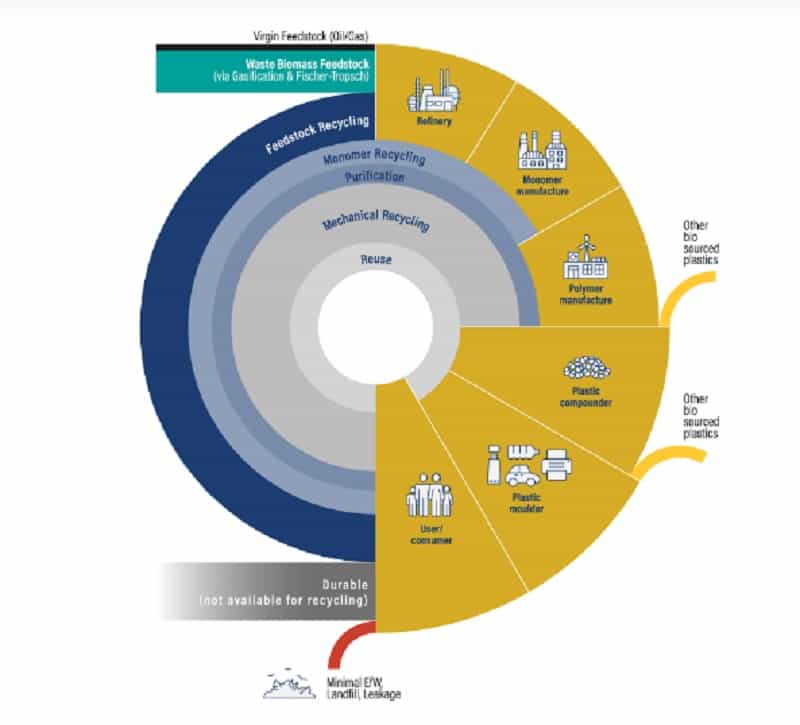

Given technological challenges with current recycling methods, new solutions are required to solve this growing problem, and chemical recycling is becoming recognised as a key component in the transition from a linear economy to a circular economy, decoupling plastic production from fossil-fuel sources and recovering value from plastic waste.

The solution

Chemical recycling is the broad term used to describe a range of emerging technologies that allow plastics that are either technically difficult to process or uneconomic to recover, to be recycled. China-textile-garment-trouble – recycled-rubber

By turning plastic waste back into base chemicals and chemical feedstocks, chemical recycling processes have the potential to dramatically improve recycling rates and divert plastic waste from landfill or incineration.

Feedstock Recycling

Converts residual plastic waste, that would normally be landfilled or incinerated, into oil that can be used by the petrochemical industry as the feedstock for producing virgin quality plastic.

Monomer Recycling

Cracks long polymer molecules back into the monomer building block, for example polystyrene into styrene, from which more polystyrene can be produced.

-Caps and bottles are now inseparable – especially when it comes to recycling

Due to an impending directive set forth by the European Union (EU), tethered caps which remain permanently attached to the bottle after opening and during use will soon be widely available for consumers across Europe. The aim of the new directive is to prevent unintended environmental waste and facilitate the recycling of caps and closures alongside their containers. A multinational beverage manufacturer shares the EU’s commitment and has introduced tethered caps from Affaba & Ferrari, a TriMas Packaging brand, for its iced tea brand.

The company has set the goal of reducing the impact of its bottles on the environment, while offering its customers an opportunity to enjoy their drinks sustainably. With Affaba & Ferrari’s new 1P23 tethered cap, the established beverage manufacturer has found a solution to meet the upcoming directive as well as its own sustainability goals.

Progressive design fulfills both sustainability requirements and customer demand

Affaba & Ferrari specialises in the production of precision caps and closures used in food, beverage, agrochemical and industrial applications. Its latest product, the tethered cap, supports companies in meeting their sustainability goals.

“Bottle caps can in fact be recycled but they are often lost, discarded or simply end up as waste. China-textile-garment-trouble – recycled-rubber

The design of our tethered caps goes a long way toward ensuring this will no longer occur,” explains Guglielmo Ferrari, Plant Manager at Affaba & Ferrari. The new tethered cap closure is attached to a safety ring through a tab which enables an ideal opening position, allowing the consumer to easily drink out of the bottle, while guaranteeing that it cannot separate from the container and be discarded. Additionally, the innovative, lightweight cap with a horizontal hinge is suitable for aseptic filling and is fully customizable to enhance the customer’s brand identity.

Entire beverage portfolio to be equipped with tethered caps over time

The beverage manufacturer has already launched the tethered cap in the Italian market, beginning with its iced tea brand. With the introduction of the new caps, the company has also reduced the amount of plastic required for each iced tea bottle cap by 14%. This is only one of the first steps in the company’s strategy to drive forward a circular economy for its plastic products. Just recently, the well-known beverage manufacturer announced its plans to use at least 50% recycled material in its packaging by 2030. It also plans to make its packaging 100% recyclable by 2025. China-textile-garment-trouble – recycled-rubber

-Neste, MAN and Altens sign a partnership to promote biofuels in France

Sharing a common vision where biofuels have a key role to play in reducing the greenhouse gas emissions in transportation – Neste, MAN and Altens have signed a partnership contract aimed at promoting biofuels in France, said Hydrocarbonprocessing.

France is a strong market for biodiesel and FAME, but many OEMs would like to see more renewable diesel, also known as HVO100, on the market. The objective of this partnership is to promote the common vision of Neste, MAN and Altens of the crucial role that biofuels can and must play in the sustainability transformation of the transportation of goods and people. China-textile-garment-trouble – recycled-rubber

“This partnership with Neste, a world leader in producing renewable diesel, and Altens, a multi-biofuel supplier in France reinforces MAN’s multi-biofuel approach,” says Jean-Yves Kerbrat, Managing Director of MAN Truck & Bus France. “MAN advocates sustainable biofuels as opposed to fossil fuels because they allow significant reductions in CO2 emissions and are easy to implement solutions in the short term,” Jean-Yves continues.

MAN Truck and Bus France as an industrial vehicle manufacturer offering several biofuel solutions (HVO100, B100 and biogas) is convinced that biofuels is a solution that is available here and now, reducing greenhouse gas emissions in the already existing vehicle fleets and engine technologies, not requiring any additional investments into these.

“Neste MY Renewable Diesel is a high-quality, high-performance fuel, a more sustainable alternative to fossil diesel, helping its users reduce greenhouse gas emissions by up to 90%* when emissions over the fuel’s life cycle are compared with fossil diesel. With Neste MY Renewable Diesel, companies can reduce their climate emissions significantly in an instant by just changing the fuel,” says Peter Zonneveld, Vice President Sales, Europe and APAC, Renewable Road Transportation at Neste. “We are committed to supporting our customers to reduce their greenhouse gas emissions by at least 20 MMtpy by 2030,” Peter Zonneveld said. China-textile-garment-trouble – recycled-rubber

China-textile-garment-trouble – recycled-rubber