Circular Economy – HDPE – Sorting 24-03-2023 - Arhive

Circular Economy – HDPE – Sorting

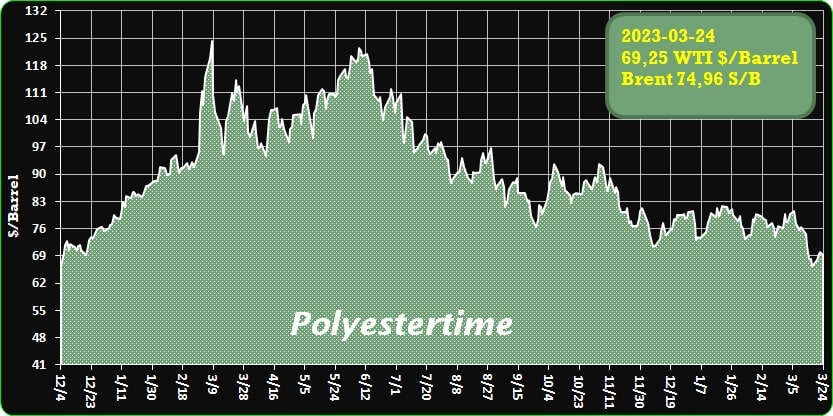

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Radici EcoMaterials is born

It is the new name of the italian company Zeta Polimeri, acquired by RadiciGroup in 2020 to boost its plastic and fiber recycling activities.

Three years after the acquisition, RadiciGroup has fully integrated the synthetic fiber and thermoplastic fiber recycler Zeta Polimeri, now renamed Radici EcoMaterials, into the group.

Based in Buronzo, in the province of Vercelli, the company takes care of all the preliminary phases of recovery, selection, processing and pre-treatment of post-consumer materials.

Its know-how joins that of RadiciGroup to give life to a virtuous production system, which procures the basic elements from sources that are now exhausted (fabrics, yarns, granules) or no longer usable in other fields, transforming them into raw materials available for other production cycles in a logic of industrial synergy.

Circular Economy – HDPE – Sorting

“It is a real circular economy activity – underlines Angelo Radici, President of RadiciGroup – which allows us to collect all the group’s waste and also those found in external companies by choosing the most appropriate destination for their recycling”.

RadiciGroup boasts forty years of experience in the recovery of post-industrial waste from its processes to give them a second life in the world of technopolymers.”With the contribution of Radici EcoMaterials’ expertise, we are now also able to guarantee extremely high quality recovery products, almost equal to virgin, at the service of our spinning mills for a textile market ready for a sustainable and low-emission offer”, he adds.

-Biden sets US goal to replace 90% of plastics with biomaterials

President Joe Biden’s administration is setting a goal of replacing 90 percent of fossil-fuel based plastics with bio-based alternatives over the next two decades.

In a report released March 22, the White House Office of Science and Technology Policy (OSTP) outlined what it called bold goals for helping the U.S. to be a leader in bioeconomy technology, produce low carbon-intensity chemicals to fight climate change and shore up domestic supply chains.

“In 20 years, [the U.S. should] demonstrate and deploy cost-effective and sustainable routes to convert bio-based feedstocks into recyclable-by-design polymers that can displace more than 90 percent of today’s plastics and other commercial polymers at scale,” the report said.

According to the report, plastics are a target because they are major greenhouse gas emitters — the size of the global aviation industry today — and are projected to grow rapidly, accounting for more than 20 percent of annual global fossil fuel consumption by 2050. Circular Economy – HDPE – Sorting

“Accordingly, an urgent global need exists to rapidly enable a more circular economy for today’s fossil carbon-based polymers production and to source chemical building blocks for tomorrow’s recyclable-by-design plastics from bio-based and waste sources,” the report said. “Additionally, waste plastics accumulating in landfills and the broader environment is well recognized as a planetary-scale pollution crisis.”

The report also set a goal of meeting 30 percent of U.S. chemicals demand from biomanufacturing over 20 years, and called for public-private partnerships to work toward the goals.

It pointed to the Department of Energy’s Strategy for Plastics Innovation program, and outlined several areas for research, including scaling up work to recycle or upcycle plastic waste, with an emphasis on multicomponent plastic waste that’s not recycled today.

It also called for redesigning plastics to improve end-of-life properties like recyclability and compostability, developing pilot processes for new polymer processing technologies and researching converting lignin and hemicellulose biomass into plastics.

-Nova Chemicals’ Vision for the Plastics Circular Economy

The company will invest $2 to $4 billion by 2030 to expand its sustainable product offerings, decarbonize assets, and build a modern mechanical recycling business.

Nova Chemicals Corp. today revealed Environmental, Social, and Governance (ESG) ambitions to drive the circular economy for plastics. The strategy aligns with its vision to become the leading sustainable polyethylene producer in North America. In summary and by 2030, the company aims to:

- Set new industry standards for driving the transition to the plastics circular economy and solidifying the market for recycled polyethylene, with 30% of polyethylene sales from recycled content;

- Be at the forefront of decarbonization by reducing its Scope 1 and 2 absolute CO2 emissions by 30%; and

- Become a Top 30 company in Canada.Circular Economy – HDPE – Sorting

“Nova’s Roadmap to Sustainability Leadership details a strong plan forward for the company to become the leader in sustainable polyethylene production while building on our commitments to developing innovative solutions for our customers, enabling the circular economy, and being a responsible steward of our environment,” says Danny Dweik, CEO. “Plastic products play an essential role in our daily lives. With our renewed purpose of reshaping plastics for a better, more sustainable world, we have developed a clear pathway to become a catalyst for a low carbon, zero-plastic-waste future.”

-Automated sorting enhances accuracy, reduces contamination

Teaching a machine to recognise compostable plastic waste

Compostable plastic can offer a sustainable alternative for conventional plastics, especially in single use packaging, bags and bio-waste bags – but only if it is disposed of in the correct manner, so that it lands in the right waste stream.

This, however, does not always happen, which means that not only are the compostability benefits lost, these materials also end up contaminating the recycling stream of other plastics – the reason many recyclers remain utterly opposed to their use.

Now, researchers at University College London have developed technology to improve the accuracy of the sorting systems used today in order to eliminate these and other contaminants from the plastics waste stream. Circular Economy – HDPE – Sorting

In a paper published in Frontiers in Sustainability they describe how they used machine learning to automatically sort different types of compostable and biodegradable plastics and differentiate them from conventional plastics.

Following their evaluation of a number of different sorting technologies, the researchers identified hyperspectral imaging (HSI), which combines imaging technology and spectroscopy into one approach, as the most effective, non-destructive technique to use.

By applying shortwave infrared (SWIR) in the range 950–1,730 nm they could identify not just different types of conventional plastics (PP, PET, and LDPE) and compostable plastic (PLA, PBAT) packaging but also compostable materials (palm leaf and sugarcane-based materials) with various sizes from 50 x 50 mm to 5 x 5 mm.

However, the amount of spectral information collected by HSI from the sample surfaces that must be processed in order to make sorting decisions in real time is huge, which led to the decision to try a novel approach using machine learning methods to differentiate and classify the different materials.

A training dataset and a testing dataset were compiled. The training dataset was the dataset used to build the classification model. It was an input into the machine learning algorithms to allow the model to associate spectral imaging data with known material classifications. The testing dataset was the dataset that contains unseen data to test the model accuracy in determining material classifications. It was used to evaluate the performance of the model. Circular Economy – HDPE – Sorting

The researchers worked with different types of plastics including PP and PET, as well as LDPE. Compostable plastic samples included PLA and PBAT, Results showed that ‘the accuracy is very high and allows the technique to be feasibly used in industrial recycling and composting facilities in the future,’ said Mark Miodownik, corresponding author of the study.

-Resin Price Report: $0.06/lb Price Hike Sought for High-Density PE

High-density polyethylene (PE), used to make milk jugs among numerous other products, is in tight supply because of force majeure declarations at three resin production plants.

Economic uncertainty fed by bank failures kept resin buyers on the sidelines last week. With the price of crude oil at its lowest level since December 2021, Prime polyethylene (PE) and polypropylene (PP) prices trended lower for the second consecutive week across the PlasticsExchange marketplace. The weaker prices were based more on waning sentiment and lack of demand than an overabundance of supply, noted the Chicago-based resin clearinghouse in its weekly Market Update. Circular Economy – HDPE – Sorting

Railcar offers remained relatively thin, and Prime was again seen for some select grades. Force majeures remain in place for PE and PP, but converters — many operating at reduced capacity — have not had any difficulty sourcing material. Export interest was also off as Asian traders lowered their bids and made competitive offers into Latin America. Undeterred by soft domestic demand, producers continue to push for March contract increases to preserve and expand margins, writes the PlasticsExchange.

Economic uncertainty fed by bank failures kept resin buyers on the sidelines last week. With the price of crude oil at its lowest level since December 2021, Prime polyethylene (PE) and polypropylene (PP) prices trended lower for the second consecutive week across the PlasticsExchange marketplace. The weaker prices were based more on waning sentiment and lack of demand than an overabundance of supply, noted the Chicago-based resin clearinghouse in its weekly Market Update. Circular Economy – HDPE – Sorting

-Avantium: Strong progress on delivering on strategic goals and the commercialisation of proprietary technologies

Key Business Progress in 2022:

- For Avantium Renewable Polymers, 2022 was a breakthrough year:

- The conditions for Financial Close were achieved, including a €90 million Debt Facilities Agreement, which allowed Avantium to begin construction of the FDCA (furandicarboxylic acid) Flagship Plant;

- Construction of the FDCA Flagship Plant in Delfzijl is progressing well, with commercial production set to start in 2024;

- Eight new offtake agreements for FDCA and PEF (polyethylene furanoate) were secured in 2022 and early 2023 with well-known brand owners and industry leaders including Carlsberg, LVMH, AmBev and Henkel. In addition, Avantium announced this morning that it has signed an offtake agreements with Kvadrat. In total 14 offtake agreements for a wide range of applications have been signed;

- The first industrial technology license agreement for YXY® Technology was signed with the US-based company Origin Materials ahead of original expectations; Circular Economy – HDPE – Sorting

- In Avantium Renewable Chemistries, operations of Ray Technology™ are back on track after a temporary pause in 2021 and preparations to scale-up to a commercial facility for plantMEG™ (mono-ethylene glycol) and plantMPG™ (mono-propylene glycol) have begun;

- For Volta Technology, two demonstration units have been successfully trialled at industrial sites in Germany and Greece;

- Avantium R&D Solutions (formerly known as Avantium Catalysis) has adopted a new growth strategy focusing on R&D solutions for sustainable chemistry, in addition to its existing offering; total revenues for Avantium R&D Solutions improved by 13%, compared with 2021, to €11.3 million.

-Berry to supply post-consumer recycled plastics for de-icing containers

Berry Global is aiming to support the sustainability strategy of a Scandinavian de-icing brands with the supply of containers made with post-consumer recycled plastic (PCR).

Berry says IS-FRITT is a range of effective de-icing products which do not contain any additives that can harm animals or nature.

Recently its manufacturer Everbrand decided that it was time to take a closer look at the packaging solution for the brand, as the company’s CEO Alexander Axelsson explained:“An obvious next step in our sustainability strategy was to change the material composition of the containers we use for IS-FRITT. Circular Economy – HDPE – Sorting

Our goal was to reduce the use of virgin plastic for packaging and to use recycled material instead while also ensuring that our containers can be recycled again after they have been used.”

The solution from the company’s long-term packaging partner Berry was to retain the existing SuperLift container but to now include 50% PCR in its manufacture.

In addition, the colour of the container has been changed from white to a shade of grey in hopes that it will strengthen its distinctiveness.SuperLift is part of the Berry PCR range, featuring an assortment of containers with up to 50% PCR material as standard, the company says that this is while retaining their benefits such as light weight, easy handling and consumer convenience. Circular Economy – HDPE – Sorting