CircularEconomy Netswaste Petrochemicals 26-05-2021 - Arhive

CircularEconomy Netswaste Petrochemicals

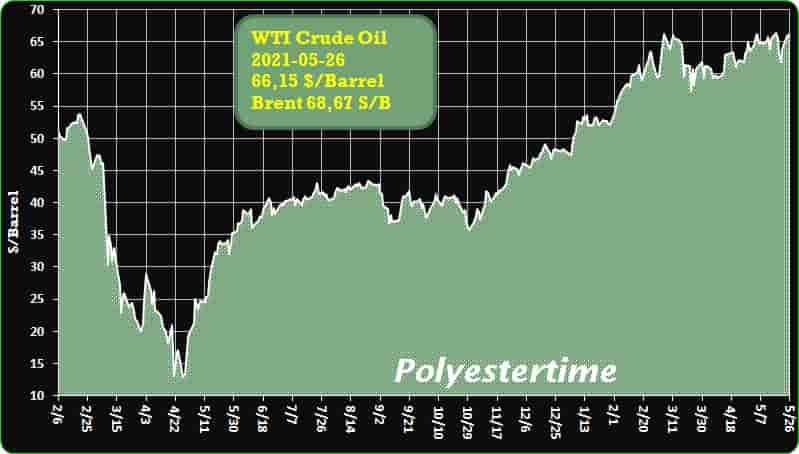

Crude Oil Prices Trend

-Circular economy: Arkema acquires Agiplast

With the planned acquisition of Agiplast, a leader in the regeneration of high performance polymers, in particular specialty polyamides and fluoropolymers, Arkema will be able to offer a full service to customers in terms of materials circularity, addressing growing market expectations in this field. This project, which contributes to the sustainable development of the polymer industry, is perfectly in line with Arkema’s sustainable growth strategy.

Arkema plans to acquire Agiplast, a company specialized in the regeneration of high performance polymers and its historical partner in recycling operations. The company, with annual sales of around €15 million, operates a plant in Italy and has 32 employees. Agiplast’s strong know-how in mechanical recycling technologies will enable Arkema to offer high quality recycled polymers to its customers.

In October 2019, Arkema, the world leader in bio-based high performance polymers, had already launched Virtucycle®, an ambitious program with Agiplast aimed at developing loops for the collection and regeneration of high performance polymers while minimizing CO2 emissions.

-The introduction of anti-dumping duties on MEG in Europe may affect PET pricing

Temporary anti-dumping duties (ADDs) on monoethylene glycol (MEG) imports to the EU from the US and Saudi Arabia may affect polyethylene terephthalate (PET) prices in the region, ICIS reported .

The preliminary anti-dumping duties on the MEG are expected to take effect on June 14, and the final measures will be taken on November 12, 2021.

The duty increase could allow other MEG producers to raise their prices where they can compete.CircularEconomy Netswaste Petrochemicals

Shipping costs have been a big concern for buyers, resellers and manufacturers since the second half of 2020 due to the pandemic.

The blockage of the Suez Canal exacerbated the problem as ships were late in loading and returning to their destination. The problem, as expected, should have been resolved by early summer. However, reports of delays beyond this period continue to be received.

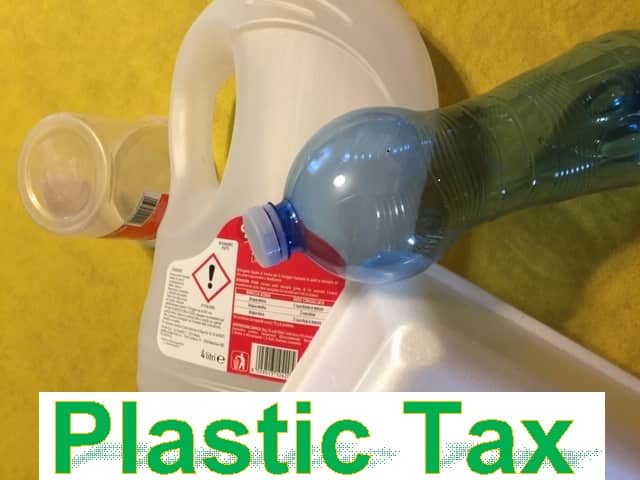

-Italy delays plastic packaging tax to January 2022

The Italian government officially confirmed that Italy’s €450/tonne plastic packaging tax will be delayed until January 2022.

Market sources based in Italy had previously reported the delay on 13 May, but there had been no initial confirmation from an official government source.

The tax has been postponed several times already.

The tax will be payable by packaging producers, with recycled plastics and compostable biodegradable plastics set to be exempt.

Full details of how the tax would be implemented had been expected in April, ahead of an expected July implementation, but have not yet been published.

The postponement of the tax follows the election of a new Italian government in February 2021. CircularEconomy Netswaste Petrochemicals

Coupled with this, Spain’s €450/tonne plastics tax faces further delays as a new draft of the government’s bill on waste and contaminated soil is sent through parliament for debate.

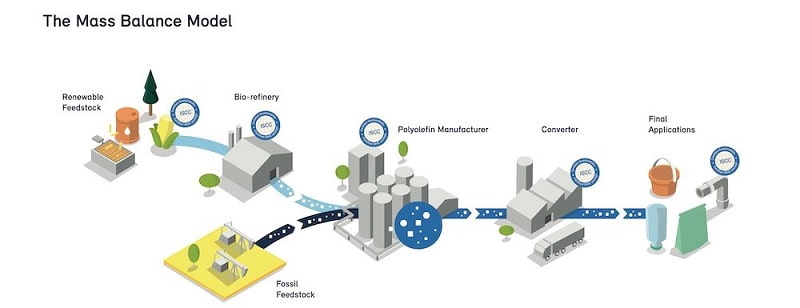

-Study reveals Borealis’ Bornewables range of PP substantially reduces GHG emissions

Borealis’ Bornewables product range of polypropylene (PP) provides significantly smaller greenhouse gas (GHG) emissions compared to polyolefins made from fossil-based feedstock, according to a new life-cycle assessment (LCA) study.

The study was carried out by ifeu, an independent ecological institutes, based in Heidelberg, Germany. They analysed the life cycle emissions of Borealis’ PP produced at its production sites in Kallo and Beringen, Belgium, when Neste’s renewable feedstock was used in the production to replace conventional feedstock.

The study showed that from cradle-to-gate (all steps from the sourcing of raw materials to products leaving Borealis’ production site), GHG emissions are reduced by at least 120% (2.7kg of CO2 equivalent per kg of PP) compared with PP manufactured with fossil-based feedstock at the same location.

Furthermore, the Bornewables are a lower-emissions alternative to virgin PP, no matter which end-of-life option is chosen. Even in case of energy recovery, when the carbon stored in the product is released, the carbon footprint reduction still amounts to 52% compared to PP from fossil-based feedstock. CircularEconomy Netswaste Petrochemicals

Helping customers meet their sustainability targets

Now proven to provide significant carbon emissions reductions when compared with virgin PP, the Bornewables are an example of what can be achieved through Borealis’ EverMinds platform, which promotes innovation and collaboration to accelerate the transition towards a more circular economy. The Bornewables circular portfolio is produced according to the mass balance model, by replacing conventional feedstock with an identical volume made from ISCC PLUS certified sustainable feedstock.

The waste sector can become a key tool in decarbonising the rest of the economy under new plans announced by Viridor, one of the UK’s leading resources and waste management companies.CircularEconomy Netswaste Petrochemicals

Ahead of COP26 in November, commitment to reach net zero greenhouse gas emissions by 2040, 10 years ahead of the Government’s legal target of 2050

New target will see the removal of at least 1.6MT of CO2 per year by 2040, equivalent to removing 783,846 cars from UK roads

Ambition to be the first net negative emissions waste and recycling company in the UK by 2045, allowing Viridor to support the rest of the economy to reach net zero by 2050

Five-step action plan to support the country to recycle 70% of our waste by 2030 and unlock billions of pounds of investment in new green technologies like carbon capture

Landmark partnership agreed to develop carbon capture technology at Viridor’s largest site as part of the ground-breaking HyNet North West industrial cluster

Viridor has set out plans to become a net zero emissions company by 2040, a target that is in line with the Paris Agreement and the Science-Based Targets initiative. Ahead of COP26 in November, Viridor is also announcing the far-reaching aim to become the first UK net negative emissions waste and recycling company by 2045, allowing it to support the country’s commitment to reach net zero by 2050.

T

-The Guardian view on recycling plastics: keep it in the UK

Editorial

Turkey is the latest country to reject the role of world’s dustbin. With their environment bill, ministers have a chance to end this vandalism

The international plastics recycling market is broken. It is doubtful whether it ever worked. CircularEconomy Netswaste Petrochemicals

For most of the last decade, China was the world’s largest importer of recyclable materials, some of which were used in manufacturing. But it banned these imports as part of a “beautiful China” policy aimed at improving the environment.

Malaysia was the next country to fight back against being treated as the “dumping ground of the world” – as its environment minister, Yeo Bee Yin, put it in 2019. More than 200 facilities were closed, and thousands of tonnes of waste returned, amid growing evidence of the involvement of organised crime in the global waste business. Now Turkey has rejected the role of international rubbish bin: after a Greenpeace investigation found plastics dumped in rivers, on beaches and in illegal waste mountains, it announced that most plastic waste imports (which included 209,642 tonnes from the UK in 2020) will be banned in six weeks’ time.

NPP POLYPLASTIC, the largest Russian manufacturer of thermoplastic composite materials, has launched the production of compounds for the production of a new commercial vehicle GAZelle, the company said.

Thus, the GAZ plant (Nizhny Novgorod) has begun mass production of a new commercial vehicle GAZelle NN with a total weight of 3.5 tons. The model of the new generation has undergone more than 50 design and technological changes, in particular, a polymer compound developed by NPP POLYPLASTIC (Moscow) with the addition of carbon nanomaterials was used for the manufacture of car wings.

It is noted that this is the first Russian polymer nanocompound for injection molding of a car wing created on the basis of domestic polyamide-6, which fully meets the industry requirements of the automotive industry in terms of both electrical conductive and physical and mechanical properties in the manufacture of external body parts. The high-tech material has all the necessary physical and mechanical properties, and the exterior parts made from it can be painted on cataphoresis lines.

“We are very pleased and proud that we have contributed to the development of technological progress in the domestic auto industry. Before GAZ, none of the Russian automakers used polymer compounds for the manufacture of exterior parts, although their molding from polymer is often simpler and cheaper than stamping from a metal sheet. CircularEconomy Netswaste Petrochemicals

The problem was that, possessing the necessary strength properties, they did not correspond to the indices for the specific volumetric electrical resistance, which are required for painting body parts in line. A separate line was required, and this was already economically unprofitable. carbon nanomaterials, from which the wings of Gazelles NN are made, makes it possible to paint the entire body of the car in line “, – said Mikhail Katsevman,Director for Science and Development, Research and Production Enterprise “POLYPLASTIC”.

-We can no longer afford to ignore plastic film

Plastic film has long been a bête noir for local authority recycling. Whether it’s plastic bags and film wrapping getting tangled in sorting machinery, or finding a market for the low-value material, Dr Sarah Kemp, Consultant at Eunomia Research & Consulting, says plastic film poses ‘headaches’ that local authorities could seemingly do without.CircularEconomy Netswaste Petrochemicals

With local authorities struggling to work out how, collectively, they’re going to achieve a 65% recycling rate by 2035, plastic film is a material stream that councils can no longer afford to ignore.

UK-wide waste composition data undertaken by Eunomia for WRAP shows that plastic film makes up 6.4% of kerbside residual waste, with just 7% of all 311,000 tonnes of plastic film put on the market in 2019 collected for recycling by 55 local authorities, according to RECOUP.

As the figures show, that’s an awful lot of material not being collected for recycling – let alone actually being recycled – and ending up in residual waste streams destined for landfill or energy recovery.

-May ABS contract prices in Europe increased by EUR70-100 per tonne

May contract prices on the European acrylonitrile-butadiene-styrene (ABS) market increased by EUR70-100 per tonne amid rising prices for styrene raw materials, ICIS reported CircularEconomy Netswaste Petrochemicals

The contract price of styrene monomer in Europe was agreed for May deliveries at EUR1,950 per tonne, up EUR87 per tonne from the previous month.

The contract price was negotiated free on board (FOB) Amsterdam-Rotterdam-Antwerp (ARA).

Prices have risen for the eighth straight month due to rising styrene prices amid limited supply and stable demand from the finished goods sector.

Supply remains limited and suppliers have low inventories, in part due to ongoing production problems in the supply chain, including force majeure by INEOS for ABS and AKN supplies. That being said, Elix ended its scheduled short service at the ABS plant last week.

Earlier it was reported that the April contract prices on the European acrylonitrile-butadiene-styrene (ABS) market increased by EUR250-300 per tonne amid rising prices for styrene raw materials by EUR312 per tonne.

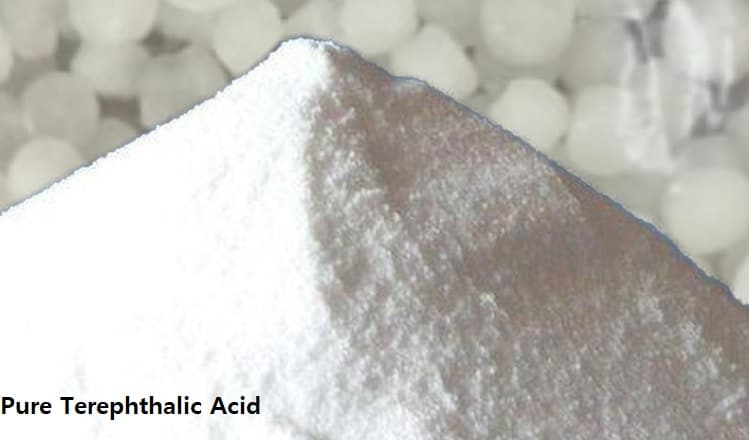

-H2 2021 PETROCHEMICALS: Asian PTA faces supply glut amid Chinese expansion, uncertain demand

HIGHLIGHTS

- New Chinese startups to weigh on Asian PTA

- Market eyes Indian demand amid pandemic

- NEA producers continue exploring exports

Market sentiment is generally bearish for the Asian purified terephthalic acid, or PTA, market due to new capacity expansions in China lined up towards the second half of 2021 — which is putting pressure on both domestic and international prices — and an uncertain demand outlook.

The demand outlook for H2 remains unclear amid new waves of the coronavirus infection in Asia, especially in India, with bottlenecks created by global logistics challenges arising from container shortages.

Despite the bearish PTA outlook, some market players are pinning their hopes on potential run-rate adjustments and capacity normalizations in China, while the effective vaccine rollout may control the pandemic and create some price support in H2. CircularEconomy Netswaste Petrochemicals

China’s mega expansion weight on profits

A total of 6.6 million mt/year new PTA capacity is expected to come online in China in H2. China’s Yisheng Petrochemical will operate the two new PTA lines which have a capacity of 3.3 million mt/year each, with one unit expected to start in July, while the other may come online around end-2021, sources close to the company said.

CircularEconomy Plasticswaste Petrochemicals