CircularEconomy Plasticswaste CO2 28-05-2021 - Arhive

CircularEconomy Plasticswaste CO2

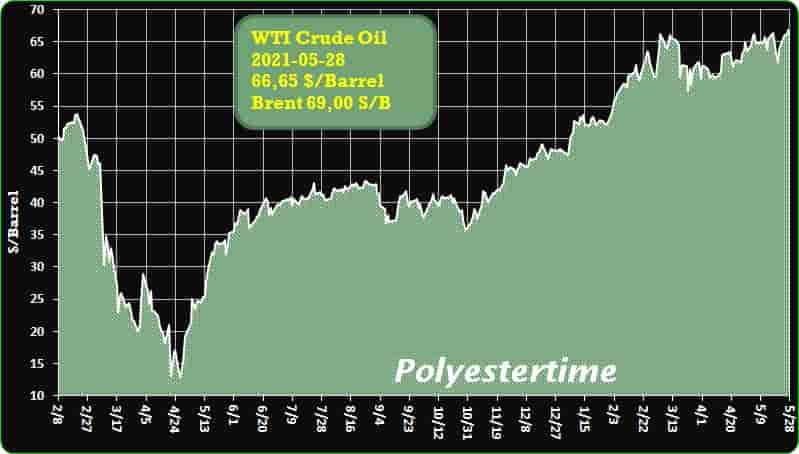

Crude Oil Prices Trend

-How Many Times Can Plastic Be Recycled?

The seven types of plastic vary in their recycling potential.

Plastic can be recycled one to 10 times, depending on the type, although most can be recycled only once. Postconsumer plastic is often turned into synthetic fibers, plastic lumber, insulation, and containers—whatever it becomes, though, will inevitably be a lower-quality item than the original product, hence why it’s called “downcycling.”

Because the heating process shortens polymer chains, thus degrading plastic quality, a water bottle can’t simply reincarnate as another water bottle—or anything food-grade, per stringent packaging requirements. However, some plastics have more recycling potential than others.

According to the ASTM International D7611 Standard, plastics can be classified into seven types, identifiable by a resin code in the center of the familiar embossed triangle. Here’s a rundown of the recyclability of each.

-AMUT completes new PET sheet line for Hickman’s

AMUT completed the start-up of a new sheet line at Hickman’s Family Farms in Arizona. The plant was designed for PET food packaging and will produce sustainable rPET egg trays. CircularEconomy Plasticswaste CO2

2021 progresses with a new ‘green’ achievement for AMUT. The company cares of the planet, by preventing post-consume PET bottles from being sent to landfill or dispersed into the environment, enabling their reuse and recycling, through various solutions ranging from sorting and washing to extrusion and thermoforming.

During the height of COVID–19 in March 2021, the recycling technology player successfully completed the training and start-up of a complete sheet line at Hickman’s Family Farms in Arizona. This custom-engineered plant has been designed for PET Food Packaging with the sustainable “Bottle to Packaging” direct process. The complete line has a capacity of 3,500 lbs/h and is equipped with a MPR to guarantee the FDA L-NO direct food contact grade of material starting from 100% Post-Consumer r-PET Flakes.

Hyperwear®, a world leader in fitness innovation, is proud to be an innovative exercise equipment maker featuring SILVADUR™ antimicrobial freshness protection technology on its SandBell® PRO sandbag training free weights.

SILVADUR™ protects the fabric on these innovative sandbag weights from odor-causing bacteria, so they stay cleaner and fresher longer. Plus, the durable SILVADUR™ technology saves time by eliminating the need to use other recommended odor control treatments after use. CircularEconomy Plasticswaste CO2

These benefits are especially important for consumers who enjoy working out at home and operators of commercial health clubs and fitness studios.

“SILVADUR™ antimicrobial technology protects the fabric of our SandBell® PRO workout sandbags from odor and makes the workout experience more effective,” states Hyperwear CEO Dirk Buikema, “Our customers can experience the versatility of one free weight to do dumbbell, kettlebell, and medicine ball exercises with the significant value of durable, advanced odor control that minimizes unpleasant distractions. For home gyms or commercial gyms, having cleaner, fresher free weight equipment with built-in odor protection just makes everything easier and more convenient.”

-Grass replaces plastic in take-away food packaging

Soon, packaging for take-away foods might be completely based on local, sustainable materials instead of fossil-based products. In a new research project, a packaging solution based on upcycled grass fibres is being developed.

Grass fibres can replace plastic as a 100% biodegradable and disposable material for packaging for take-away food. This is the goal of the new innovative project SinProPack, which aims to develop a sustainable alternative to the disposable plastics currently used for packaging. CircularEconomy Plasticswaste CO2

The project is bringing together industry, consumers and knowledge institutions to develop, demonstrate, test and evaluate fibre-based packaging for to-go food via proof-of-concept, pilot-scale trials and industrial upscaling.

“Disposable packaging made of grass brings a lot of environmental benefits. The packaging will be 100% biodegradable, so if someone accidentally drops their packaging in nature, it will decompose naturally,” says Anne Christine Steenkjær Hastrup, centre director at Danish Technological Institute, who is coordinating the project.

-Eco-friendly carbon-dioxide conversion process may revolutionize existing method

A new, environmentally friendly, single-step process has been developed to convert carbon dioxide into higher hydrocarbons using plasma, according to scientists and engineers. CircularEconomy Plasticswaste CO2

Converting carbon dioxide into usable liquid fuels and value-added chemicals like plastics offers not only a possible solution to reduce carbon dioxide emissions, but also the potential to alleviate dependence on fossil fuels. However, carbon dioxide conversion through catalysis—an acceleration of a chemical reaction—normally requires multiple steps and high temperature (roughly 400–750 degrees Fahrenheit) and high pressure (150 to 600 pounds per square inch), conditions that require a great deal of energy to create. Finding a better way to convert waste carbon dioxide under mild conditions remains a major challenge in catalysis.

Researchers from Penn State, the Chinese University of Hong Kong and Sichuan University may have found a solution. The team has developed a one-step, plasma-enabled catalytic process to convert carbon dioxide into higher hydrocarbons. Unlike traditional processes, this method of hydrogenation is operated at low temperature (75 degrees Fahrenheit) and pressure (15 pounds per square inch) using a dielectric barrier discharge packed-bed plasma reactor.

-Chemical recycling of plastic waste: working towards complete recycling

Because of their versatility, plastics make up the most widely used group of materials. They are also the most regulated in terms of safety and are used in an endless range of applications. CircularEconomy Plasticswaste CO2

While versatility is one of plastic’s most attractive qualities, this can limit its ability to be recycled using traditional mechanical recycling methods for several reasons, including: 1) the many different kinds of plastic, 2) the presence of more than one kind of plastic in the same product and 3) some plastics are designed not to melt in order to increase their mechanical and thermal resistance.

Against this backdrop, Europe increasingly calls for greater circularity in industry and society in order to maintain resources in the production system and reduce dependence on third countries, thus fostering a growing need to develop new technologies and further develop existing ones to complement mechanical recycling with the aim of achieving resource efficiency and zero waste.

Chemical recycling involves material recycling and is therefore on the same level as mechanical recycling in the waste hierarchy.

-Carpets Inter’s EcoSoft, One-Of-Its-Kind Eco-Friendly Carpets, Forays Into India

The brand’s eco-friendly carpets, tried-and-tested for more than 17 years, have been manufactured by recycling over 787 million PET Bottles

Carpets Inter, one of the leading carpet brands, is making waves in the Indian retail market with its latest alternative backing offer, EcoSoft. With this eco-friendly product, the brand brings it’s top-of-the-line high-performance and environment-friendly carpet tile cushion backing to the Indian consumer.

This next generation of carpet tile backing has been manufactured keeping in mind the need to reduce the plastic stress on the environment and has put to use millions of discarded water bottles. The brand is driven by the mission to recycle 1 billion bottles by the year 2025. CircularEconomy Plasticswaste CO2

EcoSoft is the next wave of carpet tile backing, made up of 80% post-consumer recycled PET and 5% post-industrial recycled PET re-engineered from millions of reused drinking water bottles.

This eco-friendly product not only meets the rigorous performance requirements expected from a carpet tile, but even outperforms the traditional PVC and bitumen hardbacks, as well as urethane cushion backs. In terms of longevity, walking comfort, acoustic inclination, and indoor air quality, Carpets Inter comes as a blessing in disguise with the specialised carpet tile backing.

-Indorama Ventures increases capacity in Nagpur plant

In other news, Indorama Ventures’s subsidiary Indo Rama Synthetics (India) Limited (IRSL) will spend up to US$82 million upgrading equipment and adding capacity at its manufacturing site in Nagpur, India. The capital expenditure plan includes a new PET resin manufacturing facility, additional balancing equipment, and a large range of specialty yarns, further strengthening IRSL’s ability to serve clients across the country. CircularEconomy Plasticswaste CO2

India is a strategic market for Thailand-headquartered Indorama, where the company operates all three of its global integrated business segments – Combine PET, Fibres, and Integrated Oxides and Derivatives (IOD). It adds that it has continually developed its PET resin business in India since 2016 through IVL Dhunseri Petrochem Industries Private Limited (IDPIPL), a joint venture with Dhunseri Ventures Limited.

The new PET resin facility at Nagpur will add 700 tonnes/day of capacity and is expected to be operational by the second quarter of 2022. Together with plants at Haldia and Karnal, the Nagpur facility further strengthens Indorama’s position as India’s largest resin producer, with a total capacity of over 1 million tonnes/year. With three manufacturing locations across the country, Indorama serves customers throughout India.

-German exports fall in May, Q1 trade with UK erodes on Brexit

International trade continues to evolve in the fallout of the pandemic, affecting the chemicals industry and related downstream markets.

GERMAN EXPORTS

This weighed on German producers sentiment, according to the latest data from the Ifo Institute on Wednesday, as Ifo Export Expectations for manufacturing fell to 23.0 points in May, from 23.9 a month prior. CircularEconomy Plasticswaste CO2

Despite this Germany’s export industry remained a key driver for industrial activity.

Expectations in the chemicals industry remain optimistic about export demand in the coming months.

The furniture industry is experiencing an uptick in export orders after several months of struggling with low demand.

Healthy demand was echoed in electrical and electronics industries, as well machinery and equipment manufacturing.

In contrast, sentiment in the automotive industry has fallen significantly with paltry new orders expected from overseas expected in the near term.

-Study reveals link between climate change and microplastic pollution

Marine researchers at the Galway-Mayo Institute of Technology have conducted a groundbreaking study which highlights for the first time a direct link between plastic pollution and climate change. CircularEconomy Plasticswaste CO2

The team, headed by Dr João Frias, of the GMIT Marine and Freshwater Research Centre, tested the plastic polymers known as Low Density Polyethylene (LDPE) – found in plastic milk bottles and shopping bags – and found they released the highest concentrations of greenhouse gases – including methane and ethylene – to the environment when exposed to solar radiation.

The study, entitled ‘Microplastics in the marine environment: sources, impacts and recommendations,’ is published today ahead of European Green Week 2021 next week.

It revealed the bulk of microplastic waste clogging up our oceans consists of microfibres from clothes.

It notes that the agriculture sector is responsible for the lion’s share of plastics and microplastics in the marine environment from the use of plastic seed coatings and plastic mulching and the spreading of sludge from wastewater treatment plants.

CircularEconomy Plasticswaste CO2