CircularEconomy Plasticswaste PETBottle 27-05-2021 - Arhive

Circular

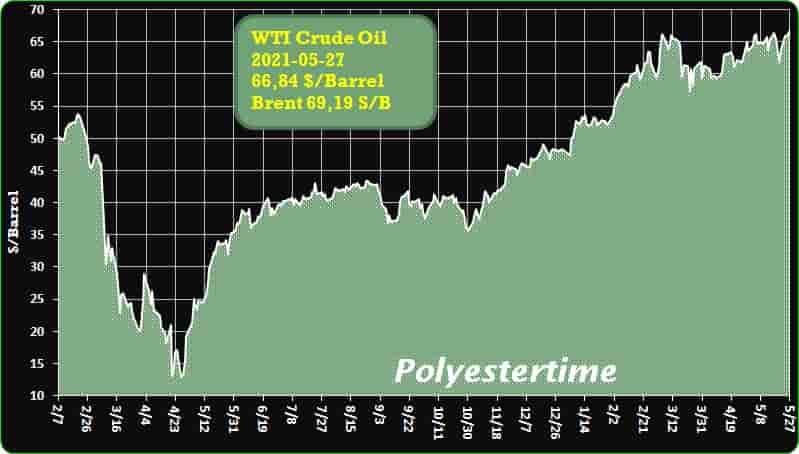

Crude Oil Prices Trend

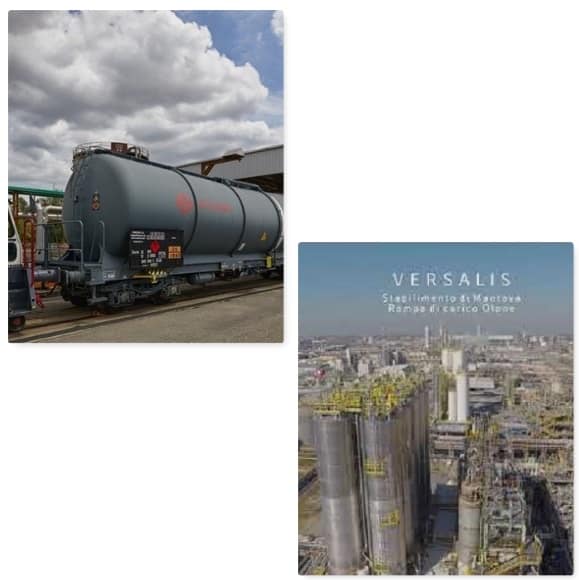

-RadiciGroup and Versalis commit to sustainable logistics

Lower CO2 emissions, energy saving and greater safety are among the key objectives of the new railway siding constructed on the Versalis plant site in Mantua, Italy, and put into service to transport KA oil to Radici Chimica SpA.

KA oil is one of the main chemical intermediates used in the production of adipic acid for PA 66 production, the core business of Radici Chimica and the basis of subsequent RadiciGroup manufacturing processes for its plastics engineering business.

Massimo De Petro, CPO for Strategic Materials and Logistics of RadiciGroup, said: “Before the railway siding was built, the intermediate went by truck from the Versalis site in Mantua to the nearby railway freight yard of Mantova Valdaro, and then travelled by rail to Radici Chimica in Novara, where there has been a goods station on the premises for some time. On account of this new investment, we can now manage KA oil logistics solely by tank car, thus ensuring greater safety in the handling and transportation of the material.”

Marco Chiappani, Head of the Intermediates Business Unit at Versalis, added: “Mantua plays a central role in the Versalis production system, the sustainability strategy of industrial processes, and also in all the support services, up to the products destined for the market. They are focused on the search for innovative and sustainable solutions, and when projects aimed at reducing the environmental impacts are developed together with other companies, a double result is achieved. Investing in more sustainable and safer logistics was an obvious choice, especially in collaboration with an established partner such as Radici Chimica.”

-Lithuanian scientists develop transparent cellulose-based bioplastic

A team of researchers at the KTU Faculty of Chemical Technology has created a fully-compostable packaging for food products from bioplastic, which disintegrates with the help of microorganisms CircularEconomy Plasticswaste PETBottle

“We are used to getting sandwiches, snacks, pastries, sweets and many other products in a paper bag with a plastic window. With a clear window on the front face, the products in the bag can be viewed easily. Although paper is biologically degradable, it is complicated to separate paper from plastic, and the package is considered non-recyclable and non-compostable. However, if we made the window from biodegradable plastic, it could be composted. Moreover, we could even use the bag for collecting biodegradable waste and put all into the compost bin together”, says Dr Paulius Pavelas Danilovas, the lead researcher of the team.

Compostability is a characteristic of a product that allows it to biodegrade under specific conditions under the influence of microorganisms.

-US COMPANY DOMTAR TO EXPAND EAM FACILITY FOR AIRLAID NONWOVENS

Domtar is set to expand its Jesup, Georgia-based Engineered Absorbent Materials (EAM) facility. The project will play an integral role in helping the company grow its position as a leading global absorbent materials and technology business offering fluff pulp and airlaid nonwoven materials. Domtar is a provider of a wide variety of fibre-based products. CircularEconomy Plasticswaste PETBottle

Domtar’s EAM facility has been developing and manufacturing innovative, high-quality absorbent core solutions since 1998. This expansion project will add a large scale Dan-Web airlaid production line to the facility. The machine will be fully operational in 2022, enhancing Domtar’s ability to supply both domestic and global customers with unique absorbent materials solutions, the company said in a press release.

-INSPECTA BE, FINALIST AT THE SUSTAINABILITY AWARDS 2021

InspectaBe has been selected as one of the finalists in the Machinery category of the prestigious award that aims to promote the spread of sustainable packaging. Specifically, InspectaBe ensures strict control over the presence of Benzene throughout the entire production chain with recycled PET.

The Sustainability Awards is the international award organised by the trade magazine Packaging Europe, which aims to spread the culture of innovation in packaging with a view to sustainability in response to such emergencies as environmental pollution and climate change. Now in its eighth year, this award in 2021 attracted 309 nominations in 8 categories with 32 finalists who will be judged by a panel of independent experts. CircularEconomy Plasticswaste PETBottle

The result of the Piovan Group’s constant commitment to innovation, InspectaBe is a analyzer designed to detect benzene in finished products – sheets and bottles – or semi-finished products – granules or preforms – with various percentages of rPET.

Benzene could be present in the finished product when residual traces of PVC remain in the PET after the post-consumer sorting process. InspectaBe allows measurements to be taken in just 60 minutes at the production site itself and, together with the Winfactory 4.0 management software, is a valuable ally to the Quality System, allowing a history of the measurements associated with production lots to be archived as proof of the safety of processes.

-Herma: New label adhesive for more assured PET recycling

New wash-off label adhesive 52W satisfies strict Scandinavian requirements for closed-loop PET recycling.

Even with standard PP films, it washes off PET bottles without leaving any residue at just 65 degrees Celsius. CircularEconomy Plasticswaste PETBottle

Special formulation ensures reliable separation of labels and PET bottles throughout the recycling process.

The Norwegian PET collection scheme has already approved the new HERMA adhesive, and the Swedish scheme recommends it.

As the drive to promote the recycling of separated plastics gathers pace, wash-off label adhesives are highly sought-after. HERMA has now developed a new adhesive specifically for PET bottles that satisfies even the very strict requirements imposed by two Scandinavian countries or their collection schemes. The new HERMA adhesive 52W has now been approved by the Norwegian collection scheme Infinitum and added to the list of recommended adhesives by the Swedish equivalent Returpack. Both the approval and the recommendation concern the adhesive in combination with the label materials HERMA PP white super tc (grade 881) and HERMA PP 50 transparent super tc (grade 886). The new adhesive ensures not only that the labels are reliably washed off the bottles without leaving any residue, but also that any tackiness which would allow the labels to stick after washing is removed. Its properties facilitate both the complete removal of the labels and the reliable separation of the PET bottles and labels. “52W enables us to ensure that label particles cannot regain their stickiness during drying and then become attached again to the washed PET flakes. In the context of separation for recycling, this is a key requirement of the Norwegian and Swedish recycling regulations.

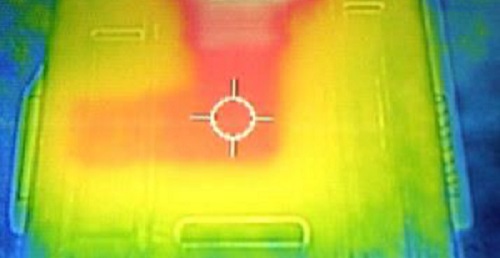

-Carbon-Fiber Composite Achieves Metal-like Thermal Conductivity

Japan’s Toray Industries Inc. has developed a thermal conductivity technology that raises the heat-dissipating properties of carbon-fiber-reinforced plastic (CFRP) to that of metals. Applying this technology to CFRP dissipates heat effectively from its sources through thermal conduction paths inside the material. This helps suppress battery degradation in mobility applications while boosting performance in electronic devices. CircularEconomy Plasticswaste PETBottle

Common applications for this light, strong, and rigid plastic include aircraft, automobiles, infrastructure components, sporting goods, and electronic devices. Boosting the heat dissipation of CFRP when it is used as a structural material in advanced mobility is important in preventing batteries from deteriorating because of heat buildup during charging. However, CFRP is less thermally conductive than aluminum alloys and other metals, prompting efforts to enhance heat dissipation by employing external or internal graphite sheets. These sheets are easy to fracture, scatter, and damage, however, and compromise the performance of CFRP.

Over the years, Toray has used proprietary technology to develop and apply rigid, porous CFRP forming three-dimensional networks with short carbon fibers. On this occasion, Toray created a heat-conductive layer employing a porous CFRP support that safeguards the graphite sheets. Laminating CFRP prepreg on this thermally conductive layer enables Toray to attain a thermal conductivity above that of metals. That would be impossible with regular CFRP without compromising the mechanical properties and quality of the material.

-Weekly Resin Report: Fasten Your Seatbelts, Hurricane Season Is Coming

Spot pricing had a mixed week with a firm undertone, reports the PlasticsExchange in its Market Update. Polypropylene (PP) finished the week of May 17 up a cent and polyethylene (PE) levels were mostly higher, with some steady. Just one grade lost ground. CircularEconomy Plasticswaste PETBottle

Though resin reactors generally have been running smoothly, most producers remain under force majeure with contract allocations still in place. The supply of fresh PE and PP railcars was again predominately off grade. Very little domestic prime was available for the spot market, though some prime liquidity was provided through forecasted orders and imported resin. Incremental PE exports were challenged by price, but Latin America and Europe emerged as notable outlets. PP exports were limited to off-grade resins, as prime is needed for contracts.

Spot pricing had a mixed week with a firm undertone, reports the PlasticsExchange in its Market Update. Polypropylene (PP) finished the week of May 17 up a cent and polyethylene (PE) levels were mostly higher, with some steady. Just one grade lost ground.

Though resin reactors generally have been running smoothly, most producers remain under force majeure with contract allocations still in place. The supply of fresh PE and PP railcars was again predominately off grade. Very little domestic prime was available for the spot market, though some prime liquidity was provided through forecasted orders and imported resin. Incremental PE exports were challenged by price, but Latin America and Europe emerged as notable outlets. PP exports were limited to off-grade resins, as prime is needed for contracts.

PE sales hampered by limited availability

While PE demand remained fairly robust last week, spot sales were limited by the lack of availability. Hefty production figures suggest that upstream inventories are improving, yet railcars of most Prime grades remained absent in the secondary market. These grades include linear-low-density (LLD) PE Hexene, high-density (HD) PE Pail Grade and 20 melt, LLDPE high flow for injection, and low-density (LD) PE high clarity for film.

-Sinopec and PetroChina cut LDPE prices in southern China

Major manufacturers in the south of China have lowered their prices for high-density polyethylene (LDPE), ICIS reports .

On May 21, Sinopec and PetroChina in southern China offered LDPE at CNY9,700 per tonne, down CNY400 per tonne from the previous day. Bids were down CNY900 per tonne compared to the previous one. CircularEconomy Plasticswaste PETBottle

As Sinopec Maoming Petrochemical is expected to restart LDPE production in the near future , there will be more supply on the market, while demand remains low.

According to ICIS-MRC Price Survey, Kazanorgsintez (KOS, part of the TAIF group) stopped part of its high-pressure polyethylene (LDPE) production facilities for scheduled preventive maintenance. On April 16, KOS completely stopped LDPE production at the third stage for annual scheduled preventive maintenance. The annual capacity of LDPE production at the third stage is 140 thousand tons.

-More than half of the plastic packaging that twenty companies spend

Analysis of plastic production shows that only twenty companies produce more than half of all discarded plastic packaging rejected in the world. She informed me about it BBC stations. CircularEconomy Plasticswaste PETBottle

A study led by a consortium of researchers led by the Australian Mindrow Foundation examined the raw materials needed to make disposable packaging, such as a thousand factories processing polymers, plastic bottles, foil and bags.

This created the first complete overview of the petrochemical companies, which form the basis of the supply chain of these products. Twenty of them make up 55 percent of the materials used to make disposable packaging, which often ends up at sea, for example.

The study also assessed which countries produce the most waste plastic waste per capita. Australia came in first, with the average population throwing 59 kilograms of plastic a year. It was followed by the United States at 53 kg and South Korea at 44 kg.

The largest manufacturer of disposable plastic packaging is the US mining company ExxonMobil. Dow, Synobeck, Indorama Ventures, Saudi Aramco, Petrosina, Lionel Basel, Reliance Industries, Broschem, Albec SADCV, Borealis, Lotte Chemical, Inios, Total, Jiangsu Hyulon Petrochemical, Pharma Group, PDT and China Resources.

-Recycled plastic prices ‘at historic highs’

The Bureau of International Recycling (BIR) says prices of recycled plastics have increased to “historically high” levels globally.

The international recycling federation, based in Brussels, attributes the rising prices to improvements in economies across Europe with the relaxation of strict lockdowns.

Henk Alssema, chair of BIR’s plastics recycling committee (picture: BIR)

Henk Alssema, chairman of the BIR plastics committee, said: “This has produced a run on raw materials, creating an imbalance between supply and demand. Experts are already talking in terms of a commodity ‘super-cycle’, which means a long period of rising prices for raw materials. The previous super-cycle started nearly 20 years ago and lasted around 10 years. CircularEconomy Plasticswaste PETBottle

“The upward trend in prices began this year and has continued to historically high levels.”

Whereas recyclers were facing poor sales and high stocks a year ago, most are now completely sold out, said Mr Alssema, – who is with Dutch recycling business VITA Plastics. He said the “extremely high demand” for recycled materials was fuelled by shortages of new prime material and that the sector was facing a shortage of input material.

CircularEconomy Plasticswaste PETBottle