CircularEconomy Plasticwaste Petrochemicals 22-05-2021 - Arhive

CircularEconomy Plasticwaste Petrochemicals

-Man-Made Fiber Technology Solutions

Trützschler Man-Made Fibers’ MO40-C BCF filament yarn extrusion system

Technology companies innovate to solve problems for the man-made fiber industry.

TW Special Report

The origins of the man-made fiber industry go back as far as the 1800s. But famously, it was the discovery of nylon by DuPont chemist W.H. Carothers almost 90 years ago that truly launched the industry. Polyester soon followed nylon; and in the years since those early discoveries, many more man-made polymers have been developed. There are lots of processes for turning these polymers into a useable fiber form, as well as downstream processes for imparting desired fiber properties. Man-made fiber technology companies continuously work to innovate for the sector, reacting to industry trends and needs.

Read on to learn about some of the latest technologies developed for the man-made fiber market.

Spinning Plants, Lines

Italy-based 4M Plants S.r.l. offers multifilament spinning plants designed for maximum flexibility and ergonomics. Its compact spinning lines are suitable for polyester and polypropylene (PP) continuous multifilament partially-oriented, fully-drawn and high-tenacity yarns. The OMNIA series offers fast installation and parameter setup to maximize return on investment and reduce production costs even on small lots. 4M reports its “plug, run and earn” claim is its standard and not merely marketing. The smallest standard Omnia may be installed and entered into production within one day.

-Bio-based Polyamide Solves Sustainability Challenge for EVA

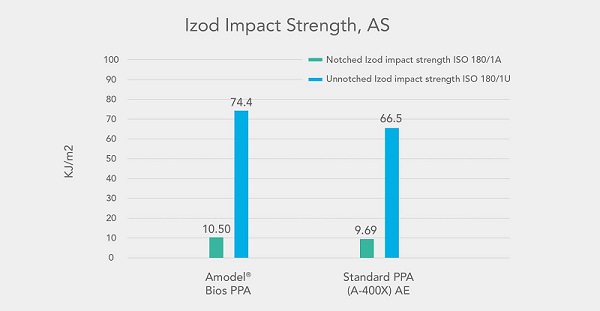

Solvay has extended its diversified portfolio of high-performance polyphthalamide (PPA) compounds with Amodel Bios, a new family of partially bio-based long-chain PPA products particularly indicated for demanding electrical and electronic applications in e-mobility. Besides its renewable feedstock content from non-food-competing sources, it is produced with 100% renewable electricity, minimizing its global warming potential (GWP) well below the level of other bio-based PPA.

Solvay’s Amodel Bios PPA combines sustainability with the requisite performance properties for components in e-motors, power electronics, and other high-end electrical systems. Most notably, it offers the highest glass transition temperature — Tg 135°C — of all bio-based PPA on the market and a melting point (Tm) of 315°C. Designed for injection molding, it is an ideal candidate for non-blistering reflow soldered surface mount devices (SMD) and parts in the cooling circuit of power electronics, including fluid connectors. CircularEconomy Plasticwaste Petrochemicals

Bast Fibre Technologies (BFT), a cleantech natural fibre engineering company, announces the closing of a CAD$8.5 million (US$7 million) series A equity financing. The Company will now enter its next phase of growth focused on the full-scale manufacturing and commercialization of natural bast fibres for nonwoven products.

US-based private equity firm Merida Capital Holdings is a key new shareholder in this series A financing which also includes significant participation from existing investors.

“With this financing under our belt we can complete the final build out of our EU manufacturing site, continue the investment in our feedstock supply chain and enter full-scale commercialization,” said CEO Noel Hall. “Since our last financing 12 months ago, we now have a large number of customers using our natural bast fibres on commercial production lines, so it is critical that we invest in manufacturing capacity to feed the strong market demand.” CircularEconomy Plasticwaste Petrochemicals

“The Bast Fibre Technologies management team has an unrivalled level of experience in both the natural fibre and nonwoven fabric markets,” said Senior Partner Mina Mishrikey of Merida Capital Holdings. “The Company’s nonwoven pipeline has the potential for immediate consumer adoption and this ESG investment complements the strategic moves we are making in the broader hemp fibre space.”

The world is facing a plastic crisis, the status quo is not an option. Plastic pollution is a serious issue of global concern which requires an urgent and international response involving all relevant actors at different levels. This page aims at listing relevant information, research, data and/or press releases issued by our partners in Geneva and other institutions around the world. CircularEconomy Plasticwaste Petrochemicals

Facing the Plastic Pollution Crisis

In this section: A glimpse on the global plastic crisis | Plastics production and the plastic industry | Plastic pollution around the world

Of all the plastic that ever existed: more than half was produced in the last 15 years and 91% has never been recycled. The Story of Plastics

A Glimpse on the Global Plastic Crisis

The world is facing a plastic crisis. Plastic pollution has become a global concern, as our planet is drowning in plastic litter and microplastics. While plastic has many valuable uses, societies have become highly dependent on single-use or disposable plastic — with severe environmental consequences. Plastic waste is now so ubiquitous in the natural environment that scientists have even suggested it could serve as a geological indicator of the Anthropocene era. How did we get here and what does this mean for us, other species and the planet? This section offers broad picture of the challenges that plastics represent to the environment.

-Chemical Recycling is a Viable Alternative to Conventional Recycling

For decades, chemical recycling has been explored as a viable alternative to conventional recycling. This type of recycling breaks plastic down into its chemical building blocks, which can then be used for fuels or as new plastics.

But, it requires a large amount of energy and with the volatile price of crude oil sometimes makes it cheaper to produce new plastic products than to recycle existing plastic. CircularEconomy Plasticwaste Petrochemicals

Chemical recycling techniques are being trialed across the world. For example, UK-based Recycling Technologies has developed a pyrolysis machine that turns hard-to-recycle plastic such as films, bags and laminated plastics into Plaxx, a liquid hydrocarbon feedstock that can be used to make new virgin quality plastic.

Eindhoven-based high-tech chemical scale-up Ioniqa Technologies announced that it has raised €10M in a fresh round of funding from a new investor and several existing shareholders.

Named ‘National icon’ by the Netherlands’ government in 2019, Ioniqa claims to be leading the pack in the field of enhanced recycling for PET plastics.

Creating value out of PET waste through technology

In the current scenario, governments, international brands, and plastic producers are setting themselves steep targets for 100 per cent recycled PET plastics, led by a major shift in consumer demands. This creates a massive pull for the circular solution Ioniqa is delivering. CircularEconomy Plasticwaste Petrochemicals

Ioniqa Technologies is a clean-tech spinoff from the Eindhoven University of Technology (NL), specialised in creating value out of PET waste by using its proprietary circular technology. With a cost-effective process, Ioniqa claims to close the loop for plastics, starting with PET plastics.

The company’s innovation transforms all types and colours of PET plastic waste into valuable “virgin-quality” materials for food-approved PET plastic. Besides, up-cycling processes for other types of plastic are also being researched and are expected to be launched in the near future by the company.

-Launch of first “E-Loop” products with recycled content

The company’s headquarters facility in Tarragona received ISCC certification in 2020

Spanish ABS manufacturer Elix Polymers (Tarragona; www.elix-polymers.com) announced the commercial availability of products with recycled content under its new “E-Loop” brand that encompasses and centralises all of the company’s circular economy activities (see Plasteurope.com of 25.02.2021).

The first quantities of its “E-Loop H801 MR black” mechanically recycled ABS/PC and its “M220 CR25” chemically recycled ABS have been produced. Validation has also come from customers in the automotive and toy industries interested in these products as part of their own circular economy strategy.

Elix Polymers plans to launch an extensive sustainable product portfolio including grades with varying content. CircularEconomy Plasticwaste Petrochemicals

-Twenty Companies Produce More than Half of the World’s Plastic Waste, Claims Report

ExxonMobil, Dow Chemical, and Sinopec are the worst polluters, according to the report spearheaded by the Minderoo Foundation of Australia.

Apparently, just 20 companies produce 55% of the world’s plastic waste, and ExxonMobil is the greatest offender. That’s one of the claims made by a study, “The Plastic Waste Makers,” produced by the Minderoo Foundation of Australia in conjunction with partners Wood Mackenzie, the London School of Economics, and Stockholm Environment Institute, among others. CircularEconomy Plasticwaste Petrochemicals

ExxonMobil, the study declared, is the greatest single-use plastic waste polluter in the world, contributing 5.9 tonnes to the global waste mountain. I always thought that companies such as ExxonMobil produced oil and gas products, such as fuel for vehicles, as well as a variety of chemicals used in automotive coolants, packaging, agricultural film, building and construction materials, and clothing. Dow Chemical reportedly creates 5.5 million tonnes of plastic waste, while China’s Sinopec produces 5.3 million tonnes. I had absolutely no idea these companies produced plastic waste!

CHEMICALS AND SUSTAINABILITY

The EU’s chemicals strategy for sustainability drafted last year, a step toward a European “Green Deal”, is taking on sharper contours. In early May 2021, the European Commission published the long-awaited update of its industrial strategy, and the constitutional session of the High-Level Roundtable, to which the trade association European Chemical Industry Council and member companies belong, took place. CircularEconomy Plasticwaste Petrochemicals

On the EU’s roadmap to sustainability, lauded by environmental NGOs as containing some of the world’s most ambitious policy recommendations, main talking points for the commission in dialogue with industry will include strengthening the chemicals legislation REACH.

The database of the European Chemicals Agency (ECHA, Helsinki / Finland; www.echa.europa.eu) has records for about 120,000 substances sold on the EU market. However, as only an estimated 22,000 of these have been registered, gaps need to be filled.

-Here Is Who’s Behind the Global Surge in Single-Use Plastic

A new report shows that a surprisingly small number of big companies and banks are behind the manufacturing and financing of much of the world’s single-use plastic.

The throwaway plastic that holds our takeout food and wraps our dry cleaning is widely seen as one of the world’s biggest environmental hazards. It pollutes as it is produced, through the extraction of fossil fuels, and, no sooner than it is used, it pollutes again. It is thrown away and can end up clogging waterways and choking animals or sometimes is burned, sending hazardous fumes into the air.

A detailed report published Tuesday sheds new light on who makes all this single-use plastic, 130 million tons a year at last count, and who makes money from it. A surprisingly small group of giant manufacturers and investors are at the heart of the global industry. CircularEconomy Plasticwaste Petrochemicals

The report comes from researchers led by Minderoo, a nonprofit organization based in Australia that advocates for cleaner oceans, along with academics at the University of Oxford and the Stockholm Environment Institute. It was reviewed by KPMG, the accounting firm.

CircularEconomy Plasticwaste Petrochemicals