Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile 06-01-2022 - Arhive

Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

-Faerch acquires dairy packaging company to boost circularity

Faerch has announced the acquisition of PACCOR, supplier of protective packaging for the dairy sector, for an undisclosed fee.

The rigid food packaging firm claims to be the world’s first integrated recycler of PET food packaging, and said the acquisition underlines its strategy for creating circularity in food packaging and will accelerate the required material conversion towards sustainable packaging.

Headquartered in Germany, PACCOR specialises in yoghurt, spreads and ice cream packaging, and is present in 18 countries.

The acquisition comprises 16 production sites in Europe, Asia and the US and more than 3,400 employees.

Andreas Schütte, chiefe executive of PACCOR, said: “Faerch’s unique integrated recycling capabilities offer fully new opportunities to accelerate the transition towards circular packaging solutions, while combining the two companies’ dedication to innovation and investments in R&D.”

Lars Gade Hansen, chief executive of Faerch Group, said: “With PACCOR becoming part of Faerch, the industry’s transition towards circularity will gain additional momentum for food packaging being recycled back into new food packaging of the same quality again and again.

“With PACCOR’s leading position in the dairy sector, Faerch will be present in all major food packaging segments, allowing the much needed standardisation away from non-recyclable legacy materials towards truly circular packaging solutions.

Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

-Piana Technology to Unveil E/SMART Nonwoven Fiber Technology

Company receives a CES 2022 Innovation Award for nonwoven fiber technology that can replace polyurethane foam

Piana Technology, a 439-year-old textile company known for innovation within the fiber and nonwoven textiles markets, announced that it has been named a CES 2022 Innovation Awards Honoree. The Innovation Award honors the outstanding design and engineering of E/SMART – a high-performance nonwoven fiber technology that surpasses the qualities of polyurethane foam while reducing its negative impacts. Piana will debut this technology at the 2022 Consumer Electronics Show, its first year in attendance, through their virtual activation experience.

E/SMART offers uncommon integration of digital wellness and product sustainability. Its recyclable and nontoxic fibers are vertically-lapped to provide even pressure point distribution, unprecedented airflow, and antiviral capabilities that outperform those of conventional materials.Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

Even at its reduced weight, it boasts superior compressional and thermal resistance for extensive applications. Flexible integrated pressure sensors within E/SMART can enable healthy posture and sleep quality through personalization of the products. Piana is developing this technology to act as a diagnostic tool in hospital settings. Combined with digitally-printed molecules, it can adapt to wide consumer requests for a user-friendly experience. At its end of life, it can be 100% reclaimed and molded for endless customer possibilities.

Replacing the 1.3 million metric tons of annually landfilled PU foam with E/SMART would eliminate over 4 million metric tons of CO2 each year, leading to reduced impact on quality of life, health, productivity and slowed environmental decline. CEO Andrea Piana sees E/SMART as an opportunity to change the way we approach sustainability. Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

“The modern world is reliant on materials of the past. If we want to maximize our human potential, we must develop new technologies that adapt alongside us,” says Piana. ” With E/SMART, we’ve built a tech platform for the circular economy with renewable materials that can be upgraded as technology improves—without waste—for endless applications. Along the way, we can make foam obsolete.”

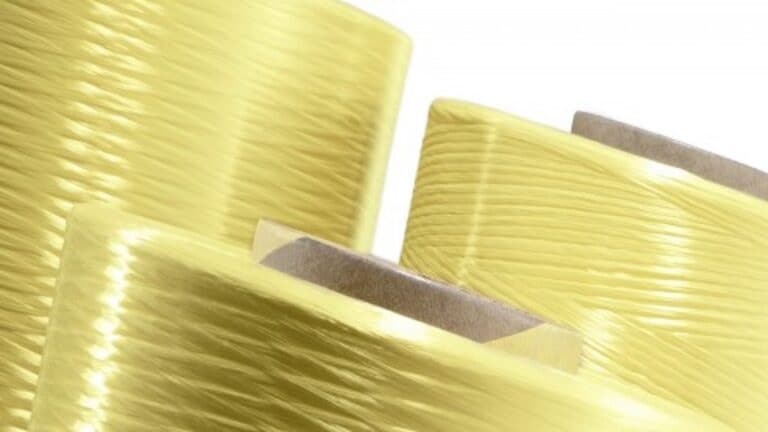

–Teijin begins life-cycle analysis of its carbon fibers

Teijin Limited has started to carry out a life-cycle assessment (LCA) of its carbon fibers to calculate their total carbon emissions—an industry first.

Teijin previously calculated the carbon footprint of its carbon fibers used in sports, recreational and industrial applications and more recently its carbon fiber filaments used in aircraft applications, which will make it possible to now calculate emissions for all of its carbon fiber filament applications.

Teijin’s LCA methodology has been certified by an independent third-party organization in accordance with the ISO14040 and ISO14044 standards and will provide customers with reliable emission data on Teijin’s carbon fiber filaments to help them evaluate their own footprints.

Teijin’s LCA is useful in identifying carbon hotspots in manufacturing processes and evaluating options for emissions reduction.

Looking ahead, Teijin expects to expand its LCA scope beyond carbon fiber filaments to also include intermediate products such as short fibers and prepregs.

Furthermore, in cooperation with customers such as final product manufacturers, Teijin eventually plans to evaluate the entire life cycle of its carbon fiber products.

The Teijin Group has set climate change mitigation and adaptation as one of the five materialities that it prioritizes as important societal issues.

Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

–New ALPLA partnership to focus on development of cellulose-based closures

The ALPLA Group has announced a joint venture partnership with Glatfelter Corporation, with both companies working with Blue Ocean Closures (BOC) to develop natural fibre-based closures and other moulded packaging products using dry forming technology. Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

ALPLA, a global packaging solutions and recycling specialist, says it is joining forces with the supplier of engineered materials, Glatfelter, to invest in the development of high-quality, cellulose-based products, which will reportedly be fully bio-based and potentially ocean biodegradable. This includes products such as screw caps.

The partnership will apparently support Swedish start-up, BOC, in its product development and shorten time to market.

According to Chris Astley, senior vice president and chief commercial officer at Glatfelter: “This partnership brings together like-minded companies that share similar sustainable objectives and goals.

“We are excited to partner with ALPLA and BOC to make more innovative and eco-friendly products that will have a lasting effect on our world.”

Lars Sandberg, CEO of BOC, comments: “In addition to a common vision for a sustainable future, they also bring enormous competencies in the field of production technology and materials science into our company.”

ALPLA adds that the partnership is part of its increased investment in the circular economy, with a particular focus on the ‘Replace’ research field for developing alternative, bio-based, and recyclable materials.

There is more innovation in plastics recycling currently than for any other material. One of the key trends in this sector is the growing use of pyrolysis and other forms of chemical recycling to reduce materials to their basic elements, and acceptance that this is more than just a flash in the pan as part of the big picture for building a viable, sustainable circular economy. Other recent developments include the use of supercritical steam to convert plastics, a redesign of 50ml PET bottles for increased recyclability and the first plastic credit exchange program is now on the ground in the U.S.

Honeywell UpCycle Process Technology expands the types of plastics that can be recycled

Honeywell recently announced the commercialization of its UpCycle Process Technology that utilizes molecular conversion, pyrolysis and contaminants management to convert waste plastic into Honeywell Recycled Polymer Feedstock, which is then used to create new plastics. The company says its UpCycle Process technology expands the types of plastics that can be recycled to waste plastic that would otherwise go unrecycled, including coloured, flexible, multi-layered packaging and polystyrene. When used in conjunction with other chemical and mechanical recycling processes – along with improvements to collection and sorting – it has the potential to increase the amount of global plastic waste that can be recycled to 90 percent.Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

-UAE-based textile division of ARISE IIP joins ITMF

The textile division of ARISE Integrated Industrial Platform (IIP), based in the UAE, has joined the ITMF as a corporate member. ARISE IIP identifies industrial gaps in African countries to unlock value and create new industries.

The aim is to industrialise key sectors by creating transformation, maximising production, efficiency, and cost, which in turn generates local value addition.

Arise IIP seeks to boost exports, enable local transformation of raw materials and promote trade by tailor-made special economic zones in Gabon, Benin and Togo.

In Benin and Togo Arise IIP will focus at creating value chains for the textile industry – from raw material sourcing to resource transformation through manufacturing, to exporting final products, ITMF said in a press release.

The International Textile Manufacturers Federation (ITMF) founded in 1904 is the international forum of the global textile value chain.

Its members are from textile and apparel producing countries representing 90 per cent of global production.

“By becoming a corporate member of the ITMF, Arise IIP will benefit from a unique international network, the expertise of ITMF, and an international platform for the global textile value chain where international trends and are discussed. Likewise, ITMF and ITMF’s members will benefit from Arise’s activities in West Africa,” said Dr Christian Schindler, director general of ITMF.

Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile

Dairy packaging Nonwoven Carbon fibers Cellulose based closures Chemical recycling Textile