Decolourised LDPE Hydrogen Packaging 12-01-2022 - Arhive

Decolourised LDPE Hydrogen Packaging

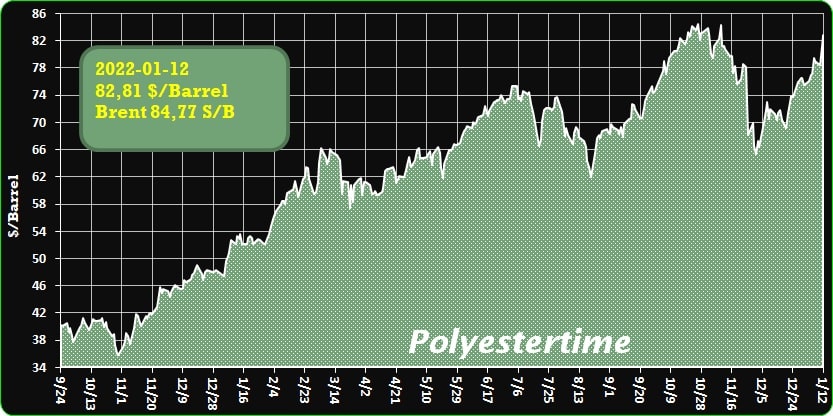

Crude Oil Prices Trend

-Hydrogen Utopia expands plastics-to-hydrogen projects in Poland

Hydropolis United has signed a Letter of Intent (LOI) with a Polish regional municipal waste management operator to develop a waste-to-hydrogen system, said the company.

The agreement between the Hydrogen Utopia International (HUI) subsidiary and Regionalny Zaklad Zagospodarowania Odpadow (RZZO) will convert end of life plastics into hydrogen. A plant can be constructed on as little as 1.5 hectares and easily bolted onto existing waste facilities, using scalable and adaptable technology.

HUI has exclusive rights in Hungary, Poland and Greece to use Powerhouse Energy Group (PHE) technology, which converts plastic into hydrogen, and non-exclusive rights in the rest of the world. RZZO will provide a plot of land for the plant and will provide the waste plastic feedstock needed to produce hydrogen, subject to the final contract. Decolourised LDPE Hydrogen Packaging

The site is expected to have capacity to process 40 tonnes of plastic waste per day to produce up to 2-3 tonnes/day of hydrogen as well as electricity and heat, with the latter likely to be fed into a district heating system.

RZZO, which was established to deal with new legislation on waste management, will also assist in procuring funding from the EU, national or local grants, and/or private funding, as well as assisting in offtake partners for the energy and hydrogen produced at the plant.

HUI’s flagship project is set to be in Konin, Poland, following an agreement between the firm and the City of Konin signed in February 2021. It is likely to come online in the next year.

As per MRC, BP announced that it has agreed Memoranda of Understanding (MoUs) with a series of new potential customers for its proposed clean hydrogen production facility in Teesside in north-east England.

In March, Bp announced plans for a clean hydrogen facility in Teesside (H2Teesside) that would aim to produce up to 1GW of ‘blue’ hydrogen – 20% of the UK’s hydrogen target – by 2030. At the same time, it announced it had signed initial MoUs to scope the supply of hydrogen to chemicals manufacturer Venator and gas distributor Northern Gas Networks.Decolourised LDPE Hydrogen Packaging

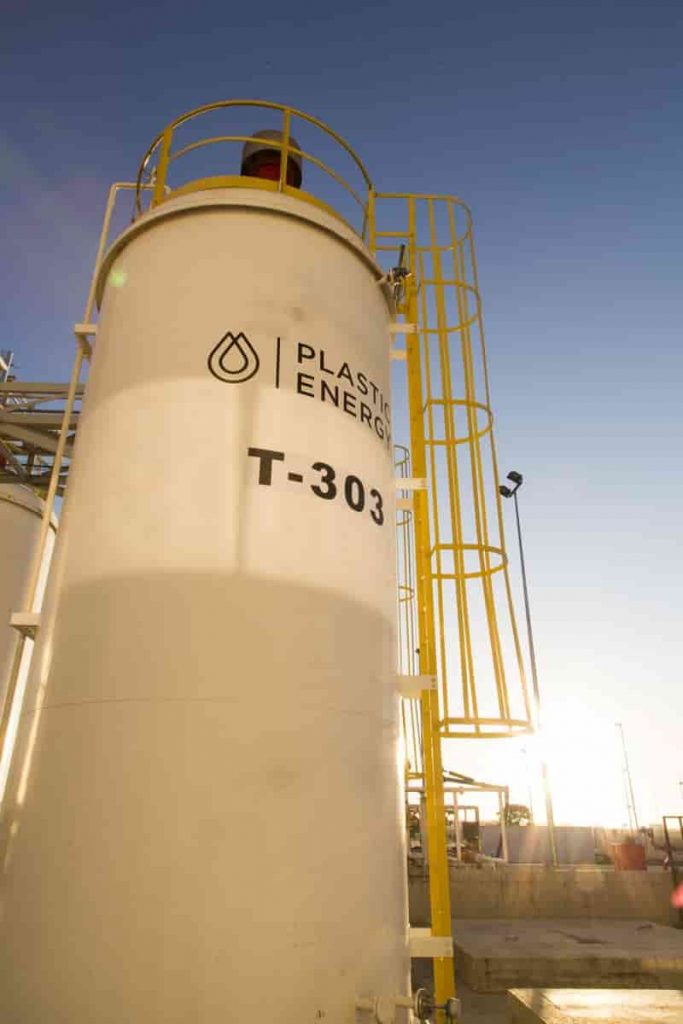

-Plastic Energy And TotalEnergies Sign An Agreement For An Advanced Recycling Project In Spain

Plastic Energy and TotalEnergies have announced a new agreement to promote the development of advanced plastic recycling. Under this agreement, Plastic Energy plans to build a second advanced recycling plant in Sevilla, Spain, in addition to their existing operational plant, which will transform end-of-life plastic waste into a recycled feedstock called TACOIL using Plastic Energy’s patented recycling technology. TotalEnergies will convert this raw material into virgin-quality polymers, which can be used for food-grade packaging. Decolourised LDPE Hydrogen Packaging

The plant will process and convert 33,000 tonnes of post-consumer end-of-life plastic waste yearly, that would otherwise be destined for landfill or incineration. The plant is expected to become operational in early 2025, with TACOIL to be used for the manufacturing of high-quality polymers in TotalEnergies’ European-based production units, following a successful processing experimentation in TotalEnergies’ petrochemical platform in Antwerp. With identical properties to virgin ones, the recycled polymers will be suitable for use in food-grade applications, such as flexible and rigid food packaging containers

Plastic Energy and TotalEnergies are both firmly committed to develop plastics recycling to address the issue of plastic waste, and to build a circular economy in Europe and globally. In line with this commitment, TotalEnergies and Plastic Energy have announced in September 2020 a joint venture to build a plastic waste conversion facility with a capacity of 15,000 tonnes per year at the TotalEnergies Grandpuits zero-crude platform in France. The project is expected to be operational in 2023. Decolourised LDPE Hydrogen Packaging

Additionally, Plastic Energy, Freepoint Eco-Systems and TotalEnergies announced a strategic partnership in October 2021 for a similar recycling plant in Texas, U.S.A. This plant, which is a joint venture between Plastic Energy and Freepoint Eco-systems, will have the capacity to recycle 33,000 tonnes of plastic waste per year, and is expected to be operational by mid-2024. Under the agreement, TACOIL will be converted by TotalEnergies in its Texas-based production units.

“I am pleased to announce another new Plastic Energy plant in Spain, and a new collaboration agreement with our partner, TotalEnergies” said Carlos Monreal, founder and CEO of Plastic Energy. “This new large-scale recycling plant will be an impactful addition to our existing portfolio of operational plants in Spain and will allow for an increase in the amount of end-of-life plastics that we can recycle in Europe.”

-APK unveils decolourised LDPE plastic recyclate

APK AG says it has been able to obtain high-quality, pure plastic LDPE recyclate from mixed consumer waste using its Newcycling technology, which it adds is successful on an industrial scale. Decolourised LDPE Hydrogen Packaging

Over the course of 2021, APK implemented an industrial-scale production campaign in several phases of its Merseburg recycling plant. The input material used with the Newcycling technology was post-consumer film waste from household collections.

According to the company, the first phase generated “excellent” results in terms of problem-free processing, yield, and mechanical values of the recyclate.

During a subsequent intermediate laboratory phase, the process parameters were refined with decolourisation in mind. The new parameters were implemented successfully in November 2021 as part of the second phase of the campaign, with the analysis of materials obtained reportedly revealing high colour and transparency values.

Klaus Wohnig, CEO of APK AG, comments: “We were able to prove that our Newcycling-technology can successfully recycle household plastic waste, and do so on an industrial scale.

“We were able to fully achieve the ambitious goals we had set for scaling and decolourisation.” Decolourised LDPE Hydrogen Packaging

Dr Jürgen Flesch, APK board member who oversees production and technology, adds: “We were able to obtain a light-coloured LDPE-recyclate from mixed, flexible household waste, which was then processed into a film.

“The L value of our ‘campaign film’ is close to that of films produced from virgin plastics.”

APK is aiming to meet the demand for high-quality recycled plastics, which it says is in “greater demand than ever”, especially in the packaging segment. The Newcycling campaign is part of its wider expansion and, alongside partners from the plastics value chain, the company has plans to establish new plants over the coming years.

–Hydrogen Utopia expands plastics-to-hydrogen projects in Poland

–Plastic Energy And TotalEnergies Sign An Agreement For An Advanced Recycling Project In Spain

–APK unveils decolourised LDPE plastic recyclate

–Indorama Ventures to Acquire Vietnemese PET Converter

–Petrobas expects to sell 100% of its preferred stake in Braskem by February

–Thermoplastic composites to replace metal components of batteries

–Crude oil prices rise sharply on Kazakhstan unrest and Libyan outages

Decolourised LDPE Hydrogen Packaging