Ecofriendly Plastics Petrochemicals PET 02-06-2021 - Arhive

Ecofriendly Plastics Petrochemicals PET

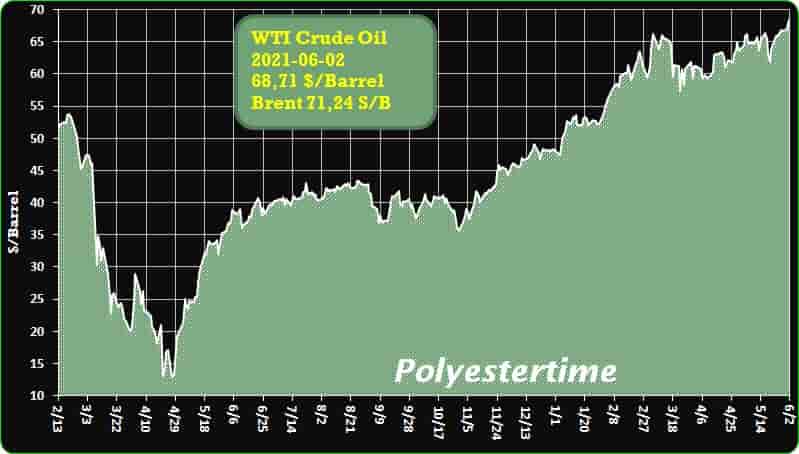

Crude Oil Prices Trend

-Gov’t Relaxes Restrictions on Recycled PET Use

New regulations aimed at promoting resource circulation and plastic recycling should see the approval of recycled transparent PET bottle use in food product packaging from next year at the earliest.

The Ministry of Food and Drug Safety (MFDS) and the Ministry of Environment jointly announced plans to amend regulations towards enabling transparent plastic bottles to be used as a packaging material for food products.

Accordingly, among the plastics gathered through the Ministry of Environment’s initiative to separate and collect transparent PET bottles for food, recycling materials that can meet the safety standards of the MFDS would be allowed to be used in the production of food containers.

-Trinseo and ETB to explore construction of bio-based 1,3-butadiene pilot plant in Europe

Trinseo, with ETB’s support, will conduct a feasibility study to explore the construction of a bio-based 1,3-butadiene pilot plant in Europe, as per Trinseo’s press release. Ecofriendly Plastics Petrochemicals PET

Thus, Trinseo and ETB have signed a letter of intent to collaborate on the development of purified bio-based 1,3-butadiene. This will see the two companies combine their respective technology and process expertise to accelerate the development of viable, renewably sourced material solutions.

Under the partnership, the companies will jointly explore opportunities to scale up ETB’s unique single-stage process to produce bio-based 1,3-butadiene from ethanol using polyfunctional catalyst technology.

The collaboration will initially focus on demonstrating the viability of sustainable ethanol-based synthetic rubber in support of green tire production. To underline this mutual commitment, the partners will conduct a feasibility study to explore the construction of a dedicated bio-based 1,3-butadiene pilot plant in Europe. Once operational, it is intended that the pilot plant will include a purification unit to achieve a purity target of 99.7%.

-Bio-based and biodegradable plastics and their role in plastics circularity

Multiple fast-moving consumer goods (FMCGs) producers and global brands have made clear their commitment to reduce the usage of conventional fossil-based plastics, with alternatives such as bio-based and biodegradable plastics have been gaining the industry’s interest. Ecofriendly Plastics Petrochemicals PET

However, are those materials the solution to plastics circularity? Confusion among terms like bio-based, biodegradable, and compostable plastics makes it hard to discern — and make — the optimum environmentally beneficial choice.

The decision of which material to use is not that simple, with several trade-offs to consider.

DO THEY FACILITATE CIRCULARITY?

The term ‘bio-based’ refers to a material made from feedstocks that have come from renewable sources– referring to the beginning of the product’s life cycle. Examples include, but are not limited to, sugarcane, corn, or cellulose.

The term ’biodegradable’ refers to a material’s ability to decompose via microbial activity – referring to the product’s end-of-life. The process of biodegradation depends on the surrounding environmental conditions on the material, and on the application.

-Technology-powered Circular Economy to Propel Waste Management in the Gulf Cooperation Council

Total waste generation in the GCC is estimated to reach 163.9 million metric tons by 2025, finds Frost & Sullivan Ecofriendly Plastics Petrochemicals PET

Frost & Sullivan’s recent analysis, Circular Economy Redefining the GCC Waste Management Market, 2021, finds that the Gulf Cooperation Council (GCC) member nations’ aspirations for sustainability are driving the replacement of linear waste management models with circular models, creating a new wave of opportunities.

Population growth and accelerated economic development are increasing total waste generation in the region (including construction and demolition (C&D) waste, municipal solid waste (MSW), plastic waste, and lead-acid battery waste).

If unchecked, this could result in an increase from 130.6 million metric tons in 2021 to 163.9 million metric tons by 2025.

A transition toward circular models is already underway, as with the UAE’s Circular Economy Policy 2021-2031 and the KSA’s Circular Carbon Economy. The policies reflect the region’s commitment to meeting the United Nations Sustainable Development Goals (UN SDGs) while enhancing the quality of life for residents.

-Japan’s Prime Polymer to build new PP plant at Ichihara

Prime Polymer Co is building a new 200,000 tonne/year polypropylene (PP) production facility at its production site in Ichihara, the Japanese producer said on Monday. Ecofriendly Plastics Petrochemicals PET

Construction of the facility will start in August 2021, with operations slated to commence in November 2024, the company said in a statement.

Financial details of the project were not disclosed.

The new PP facility will use licensed technology from Japanese producer Mitsui Chemicals.

-SE Asia braces for heavy 3Q petchem turnaround season

Olefin production losses in southeast Asia will likely peak in the third quarter of this year, Argus data indicate, with planned cracker turnarounds at major producers potentially leading to tight supplies in the region.

Aside from intra-regional consumption, olefins produced in southeast Asia are often exported to northeast Asian destinations like China and Taiwan. Total southeast Asian exports of ethylene and propylene to China reached 77,580t and 80,000t respectively in 2020. These made up 4pc and 3.2pc respectively of China’s total ethylene and propylene imports last year. Ecofriendly Plastics Petrochemicals PET

Argus expects ethylene and propylene production losses in southeast Asia to reach 551,000t and 411,000t respectively between July and September this year. The estimated production losses make up 4pc of southeast Asia’s total nameplate ethylene and propylene capacity.

-Tomra and Indorama support PET recycling in Mexico

In 2014, Indorama Ventures acquired the PET recycling Plant in Zapopan, Jal. (Mexico). Ecofriendly Plastics Petrochemicals PET

Supported by Tomra Recycling’s sorting machines, the expansion of line 2 in Indorama Ventures EcoMex was concluded this year.

Indorama Ventures EcoMex has a total production capacity of 42,000 tonnes per year of flake to be used in recycling process inside Indorama or with external customers.

As part of its commitments adopted from the 2030 agenda for sustainable development issued from the United Nations in 2015, Indorama started installing a second PET bottle post-consumer recycling production line in 2019. The line, equipped with Tomra’s sorting machines, will process 30,000 tons of PET flakes per year.

In a first step, two Autosort units presort incoming PET bottles obtained from landfills and collection centres primarily from central and western Mexico. The presort includes one positive and one negative sort plus a recirculation process for the false rejects from the first two machines.

-LEED certification for Freudenberg in Taiwan

Site has prioritised waste reduction and recycling for decades.

Freudenberg has received LEED certification for its resource-efficient, sustainable construction measures at the Tayuan Tao-Yuan site of Freudenberg Far Eastern Spunbond in Taiwan. Ecofriendly Plastics Petrochemicals PET

LEED is the acronym for Leadership in Energy and Environmental Design, and certification recognises the environmentally-responsible construction of buildings. The company took the opportunity offered by the installation of a new production line to redesign the construction of the production hall and adjoining warehouse.

Modern lighting systems, air conditioning units and restroom facilities ensure that power and water from renewable resources are used efficiently. The energy consumption of compressed air and cooling equipment was also scrutinised and optimised. In future, measuring equipment will constantly monitor and control energy and water consumption – an advantage not only in daily operations, but also for detecting leaks and other technical problems quickly.

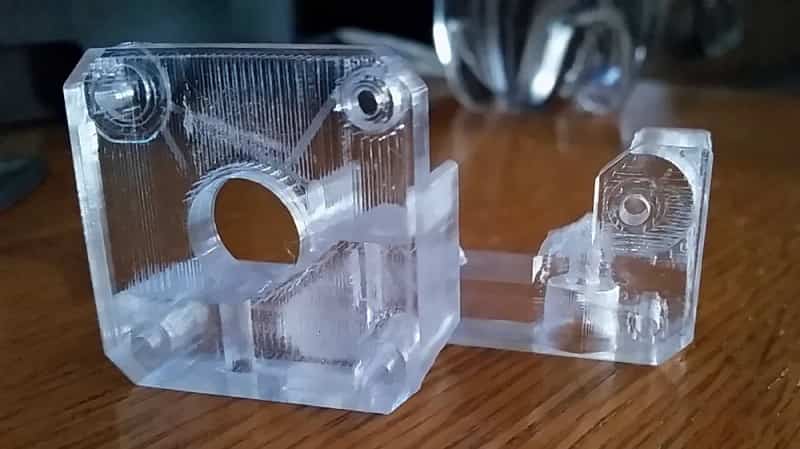

-Clear PETG Filament: The Basics & Best Brands

Clear PETG is perfect for printing translucent objects like lampshades or vases. Read on for the best options for clear PETG filament!

3D printing filaments come in many different colors and finishes, and one of the most interesting options is the color (or lack thereof) clear. Clear filament is unique because it enables you to print transparent objects, which can be used for objects that benefit from light or color passing through, like lampshades and flower vases.

It’s important to mention that, although commonly advertised as yielding transparent objects, clear filaments produce parts that are really more translucent than transparent. Ecofriendly Plastics Petrochemicals PET

That’s because 3D printers print parts layer-by-layer, and those layer lines obscure the part’s transparency. So, even if a filament is completely see-through, objects printed in that filament still won’t be completely clear.

Depending on the brand and base material, certain clear filaments are more transparent than others. For example, a clear PETG filament is typically much more see-through than a clear PLA filament. Transparent PETG filaments yield some of the clearest prints compared to other 3D printing materials, so if you’re after true transparency, you’re in the right place!

-Recycling textile waste: ‘A solution exists, we can’t go backwards’

A world-first commercial plant designed to turn fabric into raw materials will also address the vast amounts of fast fashion heading for landfill

An Australian startup working on a process to recycle textiles by turning worn-out fabric into raw materials says it has funding to build a world-first commercial-scale plant in Queensland. Ecofriendly Plastics Petrochemicals PET

The federal government held a first national roundtable on textile waste on Wednesday – recognition of a piling-up problem that results in Australians discarding an estimated 780,000 tonnes of textile waste each year, according to a 2020 national waste report.

The problem is exacerbated by the lack of an effective recycling process. Studies show many large-scale garment recycling systems provide negligible benefits and can be as environmentally harmful as producing raw fabrics.

Ecofriendly Plastics Petrochemicals PET