Enzymes Graphene Petrochemicals 05-06-2021 - Arhive

Enzymes Graphene Petrochemicals

-Ethylene Contract Prices in USA in May Decrease by USD209 / Ton

Contract prices for ethylene in the United States in May decreased by 9.5 cents per pound (USD209 per tonne) compared to April, ICIS reported .

The decline in prices is the largest since December 2008. According to the agreement, the price of the contracts is 37.75 cents per pound, which is the lowest level this year.

Ethylene spot prices fell sharply in May due to higher cracking unit productivity and continued abundant supply of liquid natural gas (NGL).

Earlier it was reported that April contract prices of ethylene in the United States rosedue to high demand and production repairs. Prices rose 0.25 cents per pound (USD6 per tonne) to range up to 47.25 cents per pound (USD1,039.5 per tonne), the highest level since October 2014.

Ethylene is the main raw material for the production of polyethylene (PE).

According to the ScanPlast review by MRC, the estimated consumption of PE in Russia amounted to 576.27 thousand tons in the first quarter of 2021, which is 4% more than in the same period a year earlier. The supply of high-density polyethylene (LDPE) and low-density polyethylene (HDPE) increased.

Venator has developed a new liquid pigment masterbatch technology that can be used to whiten recycled polyethylene terephthalate (PET) fibres quickly, cleanly, and efficiently. Based on the company’s established titanium dioxide (TiO2) platform for the fibre industry, the new HOMBITAN® LQ range is optimized for delustering PET fibres from plastic bottles that will be re-spun into polyester – ready for creating new consumer products including footwear and apparel.

Venator is launching: HOMBITAN® LQ White 100, optimized for semi-dull recycled PET fibres; and HOMBITAN® LQ White 130 for the manufacture of full-dull fibres. Designed for small scale recycled PET projects, conducted on a single extrusion line, both products are simple to use and offer several advantages over solid (pelletized) masterbatch pigment solutions. Enzymes Graphene Petrochemicals

Dosed via a precision pump, HOMBITAN® LQ products can be easily incorporated into an extrusion line. Seamlessly homogenized into a recycled polymer melt, HOMBITAN® LQ products have a higher solid pigment load than pelletized solutions – meaning fibre producers use a very small quantity to achieve comparable whiteness and opacity results.

-Korean fiber maker Huvis announces mass-production of graphene fibers

A leading Korean fiber producer called Huvis has reportedly begun to mass-produce graphene fibers. Enzymes Graphene Petrochemicals

The Company said that since graphene has such poor dispersibility, synthesis with PET (polyester) polymer is not considered easy. As a result, according to Huvis, most of the graphene fibers developed so far have either substandard graphene content, or the fiber is coated with a graphene material – which Huvis says makes them inferior (and is the reason that the graphene fibers available in the market are black or gray).

Seoul National University Smart Nano Venture developed a process that allows separating graphene as ‘superparticles’. The Smart Nano research team reportedly developed a process for single-layer, high-purity graphene in 2018, and further developed liquid graphene, not powder-type, in 2019.

Afterwards, NeoEnpla from Hwaseong/Korea, an environment-friendly plastics developer, received the graphene from Smart Nano, and from there developed the graphene masterbatch for fiber production. NeoEnpla used its proprietary technology for combining a heterogeneous material, called MEPPS (Mechanical Engineering & Polymer Processing System) that it had developed independently, to succeed with a stable combination of graphene with PET polymer.

-PolyStyreneLoop to open EPS foam recycling plant in Europe

The PolyStyreneLoop recycling plant in Terneuzen, Netherlands, is scheduled to open on the 16th of June. The plant was built to prove the technical and economic feasibility of a large-scale, closed-loop solution for the recycling of EPS waste, said the company. Enzymes Graphene Petrochemicals

A new plant built to prove the technical and economic feasibility of a large-scale, closed-loop solution for recycling expanded polystyrene (EPS) foam demolition waste from building and construction insulation will open in Terneuzen, the Netherlands on 16 June, it has been announced.

The PolyStyreneLoop facility will recycle EPS insulation using a physical recycling process based on the CreaSolv® Technology. This technology will turn EPS foam demolition waste from building and construction insulation (B&C) from the Netherlands, Germany and other countries into new high quality raw material. All kinds of impurities, such as cement or other construction residues, as well as the legacy additive HBCD, will be safely removed and valuable bromine recovered.

“This plant showcases how the EPS industry is always looking for ways to boost its recycling capabilities,” said Lein Tange, Co-Director of PolyStyreneLoop. “The purpose of this plant is to pave the way for the construction of similar EPS recycling plants in the rest of Europe.”

-BIR Convention: Can recyclers “catch ‘em all?”

Demand for recycled-content resins is putting pressure on recyclers to boost the collection of plastic scrap. Enzymes Graphene Petrochemicals

The traders and processors who collect, bale and reprocess plastic scrap may feel as if they are a player in the Pokémon universe. While their mission may not be to “catch ‘em all,” they are under increasing pressure to find enough plastic scrap to meet growing global demand for sustainable materials.

At the Plastics Committee meeting of the Brussels-based Bureau of International Recycling (BIR) 2021 World Recycling Convention, panelists in a June 2 online roundtable said they are happy to see higher prices for plastic scrap, but added that prices will have to maintain their lofty status to allow supply to meet what appears to be a new level of global demand.

Committee chair Henk Alssema of Netherlands-based Vita Plastics described a 2021 landscape of high prices coupled with it being “very difficult to fulfill supply obligations” because of shortages of material.

Finnish oil refining company Neste (Espoo; www.neste.com) is working with Japanese firms Mitsui Chemicals (Tokyo; www.mitsuichemicals.com) and Toyota Tsusho (Nagoya; www.toyota-tsusho.com) on the industrial-scale production of plastics and chemicals made from 100% bio-based feedstock. During 2021, Mitsui Chemicals will use Neste’s “RE” renewable raw materials, made entirely from bio-based waste and residue oils, at its Osaka Works site, becoming the first company in Japan to use bio-based feedstock in its crackers. Enzymes Graphene Petrochemicals

Mitsui Chemicals will produce a range of renewable chemicals, including ethylene, propylene, C4 fraction, benzene and phenol, among others, and process them into plastics such as polyethylene and polypropylene, all with significantly lower greenhouse gas emissions than their fossil-based counterparts.

-Chinese company develops clothes made of unique graphene fibers

A Chinese company called Shanghai Kyorene New Material Technology has reportedly developed a graphene fiber, that has been used to produce clothes, sports wear and underwear products. Enzymes Graphene Petrochemicals

One company that states it uses these fibers in actual commercial products is Armor Guys, a U.S-based glove maker.

The technology is said to make graphene completely integrated with high polymer materials under room temperature, and adds special function to ordinary textile products like antibacterial, ultraviolet-proof, anti-static and heat preservation effects.

Competek-Sustainable Packaging Solutions is the new player in the international packaging industry. Born from the synergy between PET Engineering and Comep, aiming to provide food, beverage and homecare packaging manufacturers with sustainable and efficient product line. Enzymes Graphene Petrochemicals

Competek is a new company whose services fully reflect the experience and know-how developed in over 20 years by two established global companies: PET Engineering and Comep. PET Engineering has always specialised in the engineering and industrialisation of new packaging solutions, with a special view to their implementation on customer lines. The core business of the French based company Comep consists instead in the development and production of moulds for PET containers – well appreciated both for their superior quality and high technology content.

The two companies joining forces to create an innovative reality whose focus and purpose is to help packaging manufacturers in the fast-evolving consumer good sector to face the challenges and changes the market requires.

One comprehensive partner

Competek, based in France but with an international vision, makes all the difference in the packaging industry by providing a full range of packaging services no matter what the customer’s platform; from packaging engineering and optimisation, to high quality moulds and change-over spare parts. An innovative service approach to fully support each customer in the evolution of their production lines.

-Caprolactam, polyamide 6: Domo explains Force Majeure for production in Leuna

Due to a technical problem at Leuna’s caprolactam plant, Domo Chemicals has declared Force Majeure for caprolactam and the follow-on product polyamide 6.

The repairs are already underway, a spokeswoman told AI. It expects the work to be completed by the end of June. Enzymes Graphene Petrochemicals

According to the AI database Polyglobe, Domo operates plants for 170,000 jato caprolactam and 110,000 jato PA 6 at the Leuna site, among other things.

-Enzymes successfully embedded in plastics

In general, plastics are processed at way over a hundred degrees Celsius. Enzymes, by contrast, cannot usually withstand these high temperatures. Researchers at the Fraunhofer Institute for Applied Polymer Research IAP have managed to reconcile these contradictions: They are able to embed enzymes in plastics without the enzymes losing their activity in the process. The potentials this creates are enormous. Enzymes Graphene Petrochemicals

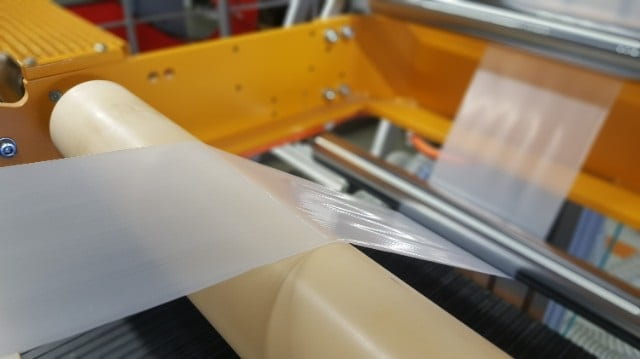

Production of a biofunctionalized film in the processing pilot plant.

Determination of the enzymatic activity of a biofunc-tionalized plastic.

Materials that clean themselves, have anti-mold surfaces or are even self-degrading are just a few examples of what will be possible if we manage to embed active enzymes into plastics. But for the enzyme-specific properties to be transferred to the materials, the enzymes must not suffer damage as they are embedded in the plastic. Scientists at Fraunhofer IAP have developed a solution to the problem as part of the “Biofunctionalization/Biologization of Polymer Materials BioPol” project. Since summer 2018, the project has been running in cooperation with BTU Cottbus-Senftenberg. The Ministry of Science, Research and Culture of the State of Brandenburg is funding the project.

Enzymes Graphene Petrochemicals