European textile – Sorting technology 08-02-2023 - Arhive

European textile – Sorting technology

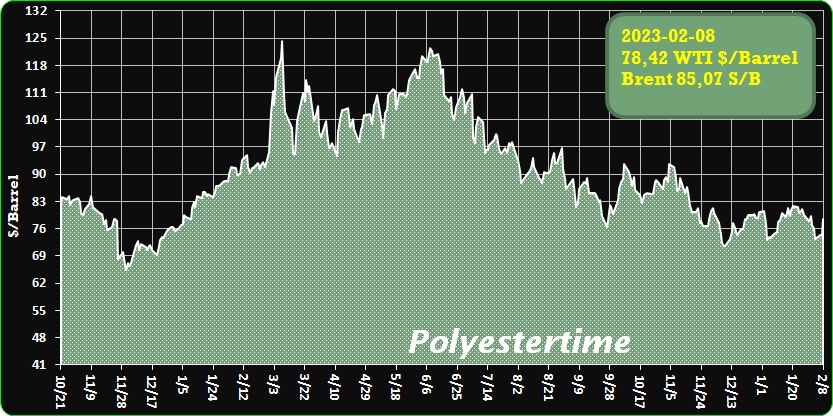

Crude Oil Prices Trend

-First automated materials recovery facility in UAE

Tomra Recycling Sorting’s sensor-based sorting technology is helping to recover high-quality, high-purity value recyclates at Farz, the first automated MRF in the United Arab Emirates (UAE). The 1,200 tons per day plant has two separate lines – one for municipal solid waste (MSW) and the other for commercial and industrial (C&I) waste. Six Tomra Autosort units are spread across the lines and used to identify and separate plastic materials from the infeed waste streams, and to sort HDPE and PET from mixed 3D plastics.

Farz is owned and operated by Imdaad, a leading integrated facility management company in the Middle East.

The plant is built on a 45,322 m2 plot in Dubai’s National Industries Park, a 21 km2 area of specially designated land in the heart of Dubai’s new industrial district. Imdaad is responsible for the collection of C&I waste from the Jebel Ali Free Zone (Jafza), a free economic zone located in the Jebel Ali area at the far western end of Dubai in the UAE. Imdaad’s mission for the Farz plant is closely aligned with Dubai’s target to hit zero waste to landfill by 2030. European textile – Sorting technology

The process

Infeed waste arrives by truck to Farz’s reception area where, following a pre-sorting stage, the MSW and C&I waste are separated into two lines; one for MSW and the other for C&I waste.

-Recycling must be favored over waste to energy

Edward Kosior says we must embrace the EU’s Packaging and Packaging Waste Directive’s goal for reaching climate neutrality in packaging.

The recent announcement of the European Commission’s new EU-wide rules on packaging has divided opinions. Starting with “leaked” reports ahead of the announcement last November, we had nongovernmental organizations (NGOs) on the one hand pressing for ambitious targets to drive our carbon footprint down and industry cautioning against unachievable goals that would depress rather than drive the sector forward.

It is indeed a fine balancing act, however, the one fundamental goal we need to keep in mind is that we must not, at any cost, exceed our carbon budget. To do so would push our already precarious climate system overboard. European textile – Sorting technology

According to an assessment presented at COP27, our remaining carbon budget to stay under 1.5 C temperature increase is 380 billion metric tons, or less than a decade of emissions at the present rate. This means emissions must be drastically reduced.

With that in mind, we need to take the macro view and consistently opt for systemic changes across every facet of our lives that are achievable and, vitally, keep us within a safe carbon range.

-SABIC, developing innovative solutions for India’s electric vehicle and renewable industry

In conversation with SABIC’s Abdullah Al-Otaibi, GM, ETP & Market Solutions, Petrochem on how SABIC continues to invest in the right capabilities and competencies for the future.

The EV and the renewable industry in India is gaining momentum and the potential for the sector is immense. Both the value chains are scouting for solutions to reduce weight, cost, and complexity and increase efficiency, durability, ease of manufacturing and safety. In conversation with SABIC’s Abdullah Al-Otaibi, GM, ETP & Market Solutions, Petrochem on how SABIC continues to invest in the right capabilities and competencies for the future.European textile – Sorting technology

1.What are SABIC’s plans and projects for the India market in the next 5-year time horizon?In the automotive space, SABIC’s focus is concentrated on developing and providing the right materials, solutions, and expertise to help the industry meet the most pressing needs of the hour. Key areas of focus for us include vehicle electrification, light weighting, LED lighting and sustainability.

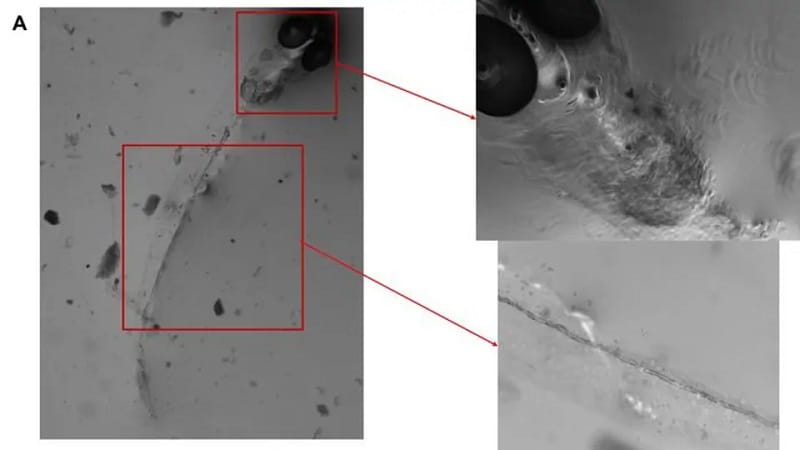

-Cotton and Synthetic Microfibers Impact Aquatic Microorganisms Too

While microplastics have received significant attention in recent years for their negative environmental impacts, a new study from Oregon State University scientists found microfibers from synthetic materials as well as cotton impacted the behavior and growth of water organisms.

“We’re trying to shift the narrative a little bit because so much of the focus has been just on the plastics, but really we need to focus more generally on microfibers of all types,” said Susanne Brander, an associate professor and ecotoxicologist at Oregon State.

“What we are seeing is that even the cotton, while it has less of an impact than the synthetic materials, still has an impact on the growth and behavior of the organisms we studied.” European textile – Sorting technology

The study, published this week in the journal Frontiers in Marine Science, is being released at a time of increased attention on regulating microfibers. Like microplastics, microfibers are of concern because scientists are increasingly identifying them in water samples and finding they are causing adverse impacts in organisms and ecosystems.

A bill was recently introduced in Oregon that would require new clothes washers sold in the state be equipped with a microfiber filtration system. France recently approved a similar measure and several other countries, states and provinces are considering bills. Related, a study from Canada in 2021 found that washing machine filters reduce microfiber emissions. European textile – Sorting technology

Brander, who studies the responses of aquatic organisms to environmental stressors, believes other measures could be taken to reduce the release of microfibers, including increasing the sustainability of clothing so that it sheds less and passing laws that would require filters on both clothes washers and dryers. Previous studies have found dryers are an underestimated source of microfibers being released into the environment.

-Report reveals “disturbing” trajectory: World produces more single-use plastic than ever before

Despite consumers calling on companies across the globe to be more environmentally friendly, the world is producing more single-use plastic than ever before, with 139 million metric tons (MMT) going into rubbish bins last year.

According to the Plastic Waste Makers Index from Andrew ‘Twiggy’ Forrest’s Minderoo Foundation, this represents a 4.5 per cent increase from 2019, meaning almost one extra kilogram of plastic was generated for every person on the planet in 2021.

The report added that single-use plastics are “not only a pollution crisis, but a climate one”, generating 450 million MMT of carbon dioxide last year – almost equivalent to annual greenhouse gas emissions produced by the UK. European textile – Sorting technology

It also found that the vast majority (98 per cent) of single-use plastics continue to be produced from fossil fuels, only a small drop from the 99 per cent recorded four years ago.

-Reusing textiles has 70x less environmental impact: European study

Reuse of textiles has 70 times lower impact on environment as compared to producing new clothing, a new life-cycle assessment (LCA) commissioned by the European textile reuse and recycling industry has confirmed. The study revealed that a substantial 3 kg of carbon dioxide (CO2) is saved for each high or medium-quality clothing that is reused.

Only a mere 0.01 per cent of the water used to produce new clothing is required for reuse, the study further stated. European textile – Sorting technology

These results come on the back of the European Union (EU) launching its strategy for sustainable textiles just a few months ago and requirements for member states to start collecting textiles separately by 2025, European Recycling Industries’ Confederation (EuRIC) said in a press release.

-MEG supply glut to continue in February

China’s MEG market will still be oversupplied in February with inventory build-up (oversupply in total MEG supply) estimated at about 200kt.

MEG inventory in East China main ports stood at 1.1 million tons at the end of January. Cargo arrivals will be intensive in the first half of February according to the shipping schedule, and MEG shore tank inventory is expected to reach 1.2 million tons.

At present, the remaining tank capacity in Ningbo and Taicang is tight. As a result, MEG floating inventory will increase.European textile – Sorting technology

In terms of China domestic supply, Fund Energy has a 10-day maintenance plan for its 500kt/year MEG unit in the second half of February. Satellite Petrochemical closed a 900kt/year MEG plant at the end of January for about 15 days of maintenance. Zhejiang Petroleum & Chemical also plans to reduce the operating rate of its MEG plant to about 60% in mid-February due to the turnaround of one of its crackers.

The start-up of Shenghong Petrochemical’s 1 million mt/year #2 MEG line has been delayed without clear timing.

However, the recovery in demand was slower than previously expected on slow resumption of work after the Chinese New Year holiday.

At present, market participants mainly choose to observe. The MEG market is likely to remain weak in the short term. Eyes could rest on the recovery of polyester polymerization rate. Effective inventory reductions would occur in the second quarter of 2023.

European textile – Sorting technology