Graphene Plasticwaste Petrochemicals 21-05-2021 - Arhive

Graphene Plasticwaste Petrochemicals

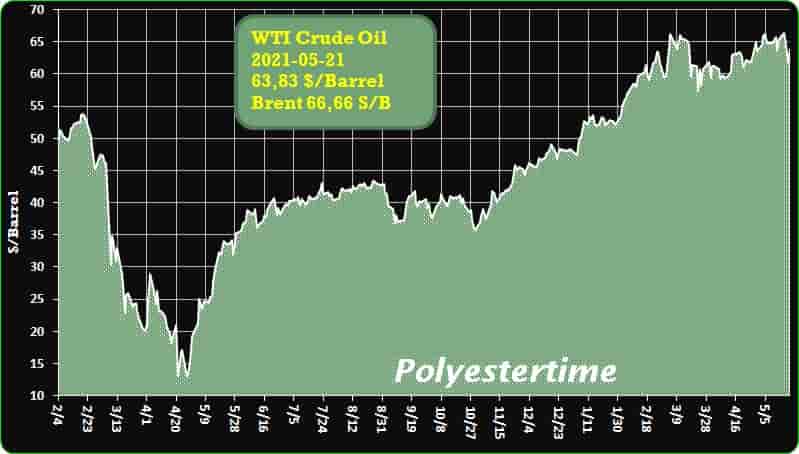

Crude Oil Prices Trend

-Plastic pollution: how chemical recycling technology could help fix it

It’s impossible to imagine everyday life without plastics. Lightweight, durable and cheap, these materials outperform many others in a diverse range of applications.

Plastics have brought about positive change in ways we often overlook. For example, the development of plastic components in electronic devices, such as the one you’re using to read this article, means we’ve never been more connected to the world around us.

But our love of plastics has come at an environmental cost. It’s been estimated that of the 8.3 billion tonnes of plastic made between 1950 to 2015, over 75% is now waste, with 79% accumulating in either landfill or the natural environment.

For scale, that’s more than all living things on Earth, and our oceans are drowning in plastic. Because of this, recent research efforts have focused on addressing these mounting environmental concerns. One of these is chemical recycling.

-Commission’s SAM report confirms role of biodegradable plastics within a circular economy

This week the European Commission’s Scientific Advice Mechanism (SAM) published a report, entitled “Biodegradability of plastics in the open environment”. The report identifies applications of biodegradable polymers which contribute towards achieving a circular economy and tackle the challenge of managing the EU’s waste.

“We are pleased to see that this report clearly identifies several beneficial application areas for biodegradable plastics even though this was not its original focus”, says Hasso von Pogrell, Managing Director of European Bioplastics (EUBP). “We also welcome the call for economic incentives to promote appropriate disposal behaviour as well as the need for further research that it highlights”, he adds.

Von Pogrell further comments: “The SAM report emphasises the advantages of applications from biodegradable plastics ‘where it is challenging to remove or collect a particular plastic product or its fragments from the environment after use’. Mulch films made from conventional plastics, for example, are widely used in European agriculture. Graphene Plasticwaste Petrochemicals

The challenge of plastic accumulation in soil can be tackled with the soil-biodegradable alternative.”

EUBP was pleased to note that the report also highlights the benefits of biodegradable plastic products “where it is difficult to separate plastic from organic material that is destined for a composting waste stream or wastewater treatment”. Packaging highly contaminated with food scraps, cannot be mechanically recycled and will be incinerated or, even worse, landfilled.

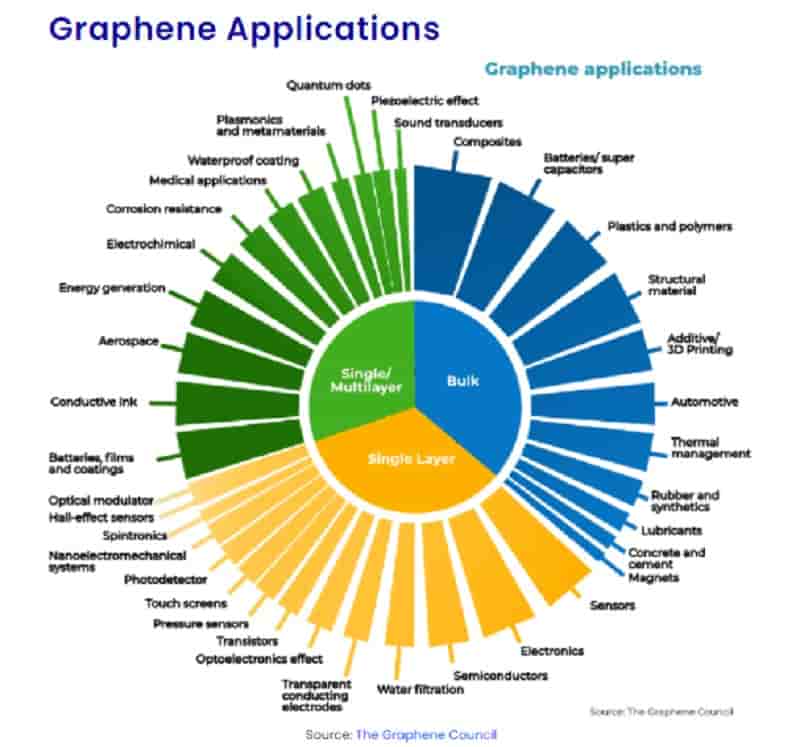

-Graphene Quality : A Key Factor

Currently graphene has neither global standard nor reference material. So, how can the quality of graphene be assessed?

Technical data delivered by graphene manufacturers does not easily allow a comparison of the different forms of graphene.

Firstly, the type of analysis methods differ a lot and secondly it can be questionable if the analysis is systematic. Graphene Plasticwaste Petrochemicals

Research conducted by the National University of Singapore (NUS) proposes a protocol to analyse and to compare the quality of graphene.

The quality of graphene from 60 manufacturers was analysed with the conclusion that the graphene is generally low quality and non-optimal for many applications.

It tends to show that most graphene manufacturers produce graphite micro-platelets.

Nowadays several local initiatives are taking shape, in order to develop programs for the verification of graphene quality.

In Europe, this work is setted up in cooperation with the LNE and INERIS.

-Plastics waste report “misleading” clami US associations

A report that identifies 20 companies as the source of half of all single-use plastics thrown away globally, has been rubbished by the Plastics Industry Association (PLASTICS) and the American Chemistry Council (ACC).

The Minderoo Foundation’s Plastic Waste Makers Index claims that a small group of petrochemical companies that manufacture polymers are the source of the problem, headed by ExxonMobil, which the report says contributed 5.9 million tonnes to global plastics waste. Other names on the list included Dow and Sinopec. The report claims that 100 companies are behind 90 per cent of global single-use plastics production, while 60 per cent of the commercial finance funding single-use production comes from 20 global banks. Graphene Plasticwaste Petrochemicals

Responding to the report, PLASTICS said: “This biased study – funded by the iron ore industry – simply does not pass the smell test. Objective study after objective study has made clear that plastics has lower greenhouse gas emissions when compared to alternative materials across a wide variety of applications.

-Oil price could hit a different kind of peak oil in the years ahead

The oil price took a hit from rumors that a deal was close with Iran on curtailing its nuclear program, the quid pro quo of which would be easing of the oil export restrictions the US has tried to enforce since former President Donald Trump walked away from the deal in 2018.

The oil price had been making a recovery since late March. Global demand picked up and OPEC+ has seemingly taken a cautious stance toward increasing output.

Oil price and Iran talks Graphene Plasticwaste Petrochemicals

But the prospect of somewhere in excess of 700,000 barrels a day of additional Iranian supply hitting the market — not to mention the millions of barrels Iran has sitting in storage waiting to hit the market — signaled profit taking for investors, who headed for the door. In turn, that prompted a sharp price fall.

Almost as quickly, a clarification from the Russians that talks have had seen any progress saw an about turn. As a result, prices largely recovered.

But the sensitivity to the prospect of an Iranian resumption of sales shows just how fragile the market is. Furthermore, it shows how effectively OPEC+ has managed expectations to date.

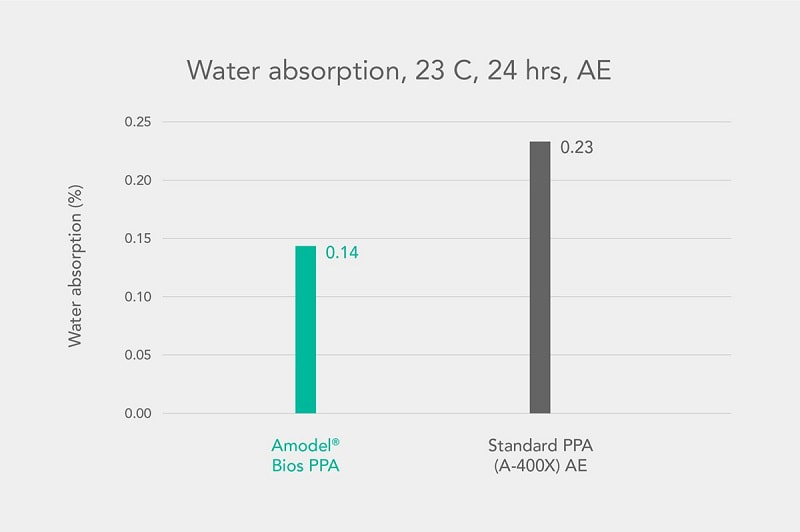

-Partially Biobased High-Performance PPA Compounds

Solvay’s Amodel Bios family of partially biobased long-chain PPA products geared to E&E applications in e-mobility. Graphene Plasticwaste Petrochemicals

A diversified portfolio of high-performance PPA compounds from Solvay Specialty Polymers has been now extended with a new family of partially biobased long-chain PPA products particularly indicated for demanding electrical and electronic (E&E) applications in e-mobility. Besides its renewable feedstock content from non-food competing sources, the new Amodel Bios PPA family of compounds is produced with 100% renewable electricity, minimizing its global warming potential (GWP) well below the level of other biobased PPA, according to the company. Globally launched, it is initially available in four grades differentiated by custom-tailored property profiles for structural, electrification and flame-retardant applications.

Solvay’s Amodel Bios is said to combine exceptional sustainability with outstanding performance properties for components in e-motors, power electronics and other high-end electrical systems.

-Solid Growth Forecast for the Plastics Industry

Frost & Sullivan predicts that global revenue for the plastics sector will expand almost 5% this year. In a new report, the business consultancy highlights the trends driving this growth. Graphene Plasticwaste Petrochemicals

The plastics industry is forecast to reach a compound annual growth rate (CAGR) of almost 5% this year as markets and consumption rebound from the business impact of COVID-19. Key trends shaping the global plastics and composites industry in the years ahead include, perhaps paradoxically, sustainability driving new product development and continued high demand for single-use plastics. Those are among the takeaways from new analysis published by Frost & Sullivan.

In its report, “Industry Convergence to Transform the Global Plastics and Composites Market, Outlook 2021,” Frost & Sullivan predicts that global revenue will rise to an estimated $558.71 billion this year, up from $533.04 billion in 2020, a CAGR of 4.8%. The business consultancy credits progressive containment of the pandemic and resumption of activity in major end markets for the growth.

-BP and Eni to form energy company in Angola

BP and Eni have entered into talks to merge their oil and gas operations in Angola to form one of Africa’s largest energy companies, said Reuters.

The two companies have signed a non-binding memorandum of understanding and are in discussions on a joint venture that will include their LNG facilities, they said in a statement. A business plan will be agreed to allow the companies “to capture future opportunities in exploration, development and possibly portfolio growth, both in Angola and regionally.” Graphene Plasticwaste Petrochemicals

Spinning off oil and gas assets is seen as a way for BP and Eni to squeeze more out of their oil and gas assets as the two companies prepare to shift towards renewable energy. The two companies have successful joint ventures in Norway, which serve as a model for the Angolan model.

-Sweden’s Polygiene & Brazil’s KVRA launch odour-free jiu-jitsu uniform

Sweden-based Polygiene, the leader in branded stays fresh technologies, has partnered with Brazilian brand KVRA, to become the first company in the world to offer jiu-jitsu gis treated with Polygiene Stays Fresh technology. Polygiene treats clothes, accessories, home products, and textiles to help stay fresh and let clothes and products live longer. Graphene Plasticwaste Petrochemicals

The gi, also known as a kimono, is the traditional uniform for jiu-jitsu, a popular martial art in many countries, including Brazil. It is made from a thick fabric, and the wearer tends to sweat heavily when performing. A typical gi can take as long as two days to dry after being in the laundry, leading many users to purchase two or three so they can be wearing one while the other is being washed and dried. Thanks to Polygiene technology, all this can change, and athletes will be able to use the same gi multiple times, meaning they only need to invest in one and can therefore upgrade to a more premium garment, according to a press release by Polygiene.

Polygiene Stays Fresh technology provides odour control by inhibiting the growth of odour-causing bacteria and stops the odour at the source, for the life of the garment. It, therefore, reduces the number of times a product needs to be washed, saving energy, time, and money, according to Polygiene.

-Braskem and Vartega Launch New Carbon Fiber Recycling Program for 3D Filament

Carbon fiber reinforced polypropylene filament recycling provides for a circular pathway for material re-use and supports sustainability goals around eliminating plastic waste Graphene Plasticwaste Petrochemicals

Braskem , the largest polyolefins producer in the Americas and leading producer of biopolymers in the world, announces today its expanded partnership with Vartega Inc. (“Vartega”), a leading recycler of advanced materials including carbon fiber reinforced plastics, for a new 3D Printing Filament Recycling Program.

Recently, Braskem expanded its 3D printing product portfolio to include new, innovative carbon fiber reinforced polypropylene filament for 3D printing (“CF-PP”) (“FL900PP-CF”). This product is made from 100% recycled carbon fiber supplied by Vartega and optimized for use with Braskem’s polypropylene.

Every box of Braskem’s carbon fiber reinforced polypropylene filament sold will include information about how to recycle the used carbon fiber filament through this program. Each year 24,000 tons of carbon fiber waste is sent to landfill every year.

Graphene Plasticwaste Petrochemicals