Green-Hydrogen – Plastics-recycling 24-01-2023 - Arhive

Green-Hydrogen – Plastics-recycling

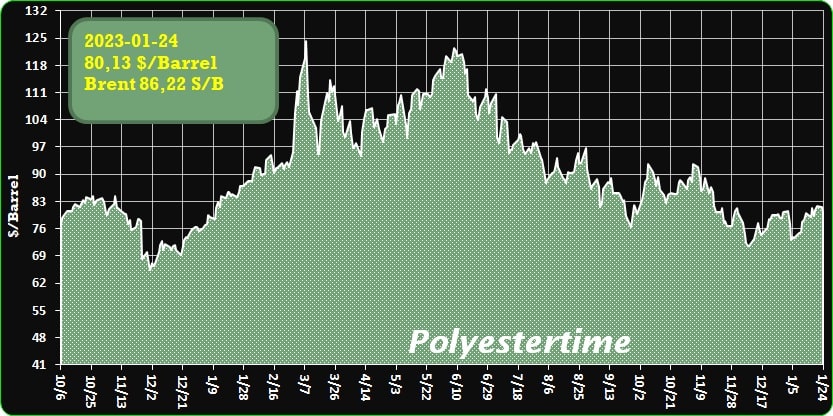

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Study compares PET recycling methods

A study conducted by the National Renewable Energy Laboratory evaluated various PET recycling methods from technical, economic and environmental standpoints to provide a big-picture overview of today’s options.

The research, published by the American Chemical Society, found that mechanical recycling outperformed all other technologies as well as virgin plastic production across economic and environmental considerations, but it ranked lower in technical metrics.

Of several available chemical recycling methods for PET, glycolysis “offered the best economic and environmental performances,” the study found, with areas for future improvement including process yields, consumable reduction or replacement, utility decarbonization and closed-loop recycling for polyolefins. Green-Hydrogen – Plastics-recycling

“Chemical recycling” generally refers to a wide array of processes that use heat, pressure and solvents to break down the molecular chains of polymers into liquids or gasses that can then be processed into fuels, oils, waxes, new plastics or other chemical products.

-Nordic Plast invests €2.8 million in modernization and development

Nordic Plast, a polyethylene (PE) and polypropylene (PP) recycler in the Baltics, belonging to Eco Baltia, the largest Baltic environmental and waste management group, has invested €2.8 million into a new sorting line.

Nordic Plast, a leading Latvia-based polyethylene and polypropylene recycler that is part of Baltic environmental and waste management group, Eco Baltia, has completed a modernisation project that involved a €2.8 million investment into a new, automated sorting line. The company says the new line will raise its recycling capacities by upwards of 30% as well as provide a significant boost to production quality and efficiency. The company was previously largely dependent on manual sorting for its packaging sorting operations, which limited its growth in production capacity, it said.

The new equipment will make it possible to process materials of various purity, enabling the sorting of even the more difficult packaging streams, for which recycling rates have remained consistently low. Green-Hydrogen – Plastics-recycling

In the European Union, plastic packaging recycling goals are set to rise from the current 22% to 50% of the total volume of marketed plastic packaging by 2025.

-“Better Future”: Innovia Films Unveils New Communication Campaign

- Campaign underpins the importance of material science in creating more sustainable packages for consumers

- Highlighting 90 years of Innovia being dedicated to innovation and progress

Innovia Films just announced the launch of their new communication campaign “Better Future”. The campaign underpins Innovia‘s role in creating better and more sustainable and recyclable materials for the future, which are used in consumer packaging, labels and for graphic films. Their long history in being a global innovator – and the leading manufacturer of BOPP (polypropylene) film.Green-Hydrogen – Plastics-recycling

As the name Innovia suggests, it’s all about innovation, the future and progress. Innovia attaches great importance to further developing its products in such a way that they meet future requirements, both from the customer’s point of view and in a sustainable sense. Hence the new claim: ‘Pack for progress’ and the headline mechanics: ‘We give the future a better label/package/print’, when developing sustainable and recyclable packaging that will benefit our environment using the base materials are essential.

Innovia Films has been a global player for the past 90 years and continues to play an enormous role in material science. “That is at the heart of what we do. We wanted this reflected in our internal and external communication,” says Guenther Birkner, President of Innovia.

-Unigel to invest up to USD1.5 bln in ‘green hydrogen’ production

Brazilian chemical maker Unigel said it will invest up to USD1.5 billion in its complex in the state of Bahia to produce so-called green hydrogen, the first in the country to do so on an industrial scale, said Reuters.

The plant, located in the city of Camacari, should have the first of three phases inaugurated by the end of 2023, expanding capacity until it achieves production of 100,000 tonnes of hydrogen by 2027, or 600,000 tonnes of one of its derivatives, ammonia. Green-Hydrogen – Plastics-recycling

The green hydrogen, obtained from the conversion of wind or solar energy, will use electrolysers to be supplied by Thyssenkrupp Nucera.

We remind, Unigel announced plans to build a green hydrogen plant in the northeastern state of Bahia, with an initial investment of USD120 million and the goal of making it one of the largest of its kind in the world. The plant will starts its production planned for late 2023. At this moment, Unigel’s integrated green hydrogen and green ammonia plant is expected to be the largest in the world. In the first phase of the project, Unigel installs three 20 MW standard electrolyzers from thyssenkrupp nucera, adding up to a total capacity of 60 MW.

-Battery Council International joins Global Battery Alliance

North American battery manufacturers are recognized as an industry association partner to support a circular battery value chain by 2030.

Battery Council International (BCI), Chicago, has joined the Global Battery Alliance (GBA), a public-private collaboration platform founded in 2017 at the World Economic Forum to help establish a sustainable battery value chain by 2030.

According to a news release from BCI, the GBA brings together leading international organizations, NGOs, industry actors, academics and multiple governments to align collectively in a precompetitive approach to drive systemic change along the entire value chain. It provides its more than 120 members with a collaborative platform to pool expertise and achieve shared goals of circularity, environmental protection and sustainable development. Green-Hydrogen – Plastic-recycling

“The GBA is pleased to welcome BCI to its growing membership base,” says GBA Executive Director Inga Petersen. “Cooperative multistakeholder engagement among critical stakeholders is necessary to realize our vision of a sustainable and responsible battery value chain, and we look forward to working with BCI in making our vision a reality.”

-UAE to launch the first food-grade plastic recycling plant

The 40,000m2 facility in Abu Dhabi could create 100 jobs and avoid the emission of 18,000 metric tonnes of CO2 annually

The Ministry of Industry and Advanced Technology (MoIAT) oversaw the signing of a Memorandum of Understanding (MoU) at Abu Dhabi Sustainability Week (ADSW), which will lay the groundwork for a new plastic recycling facility in the UAE.

Under the plans, a 12,000 tonnes per annum polyethylene terephthalate (PET) recycling plant has been earmarked for Abu Dhabi.

In line with the UAE’s efforts to reduce plastic pollution and boost trade through the export of recycled materials, the plant will recycle PET, a plastic material that is used in food packaging, such as plastic water bottles.Green-Hydrogen – Plastics-recycling

The 40,000m2 facility in Abu Dhabi could create 100 jobs and avoid the emission of 18,000 metric tonnes of CO2 annually at full operating capacity.

Omar Al Suwaidi, Under-Secretary of MoIAT, said: “Collaboration is the key driver behind the shift towards a more sustainable industrial sector and a greener economy. Accordingly, the ministry focuses on facilitating partnerships between stakeholders, including financial institutions, national industrial companies, and global corporations, with the aim of supporting GDP growth as well as the UAE’s net zero strategic initiative.”

-Sabic sets carbon goals at WEF meet

Driving circularity for plastics

Sabic, a global chemicals industry headquartered in Riyadh, has reaffirmed its commitment to accelerating the circular carbon economy during the World Economic Forum (WEF) annual meeting in Davos by unveiling its ambition to process one million metric tons (1000kt) of Trucircle solutions annually by 2030. Sabic used its reception hosted in the company’s iconic Icehouse (Innovation for the Circular Economy) with global business figures and policymakers, to outline its new advances on its sustainability journey. Green-Hydrogen – Plastics-recycling

Abdulrahman Al-Fageeh, Sabic CEO (A) said, “At Sabic, we are committed to helping provide our customers with more sustainable solutions, and our target of one million metric tons of Trucircle solutions by 2030 intends to help usher in the new circular economy.” He added, “Driving circularity for plastics will require a rapid transformation of the entire value chain, which is only possible through collective action, innovation, and collaboration across the industry and eco-system of waste management. We are working hard with downstream and upstream partners to accelerate this process.”

Sabic pioneered the industry back in Davos in 2019, when it announced plans to build a world-first small-scale commercial unit to produce certified circular polymers from the advanced recycling of used plastics. Since then, Sabic has been employing existing facilities to process smaller volumes of advanced recycled materials for brand owners and customers for a variety of applications already available in the market.

Construction of the company’s first commercial unit in Geleen, the Netherlands, is now entering the final stages and deliveries of the first circular polymers are expected in 2023.

As a next step on the roadmap to meet this 2030 target, Sabic will upscale volumes globally of advanced and mechanical recycling as well as bio-based materials. In that context, Sabic announced it is exploring a new world-scale commercial advanced recycling investment that would have a potential capacity to process around 200 kilotons (KT) of circular materials per year, as well as other projects such as a small-scale advanced recycling plant in Saudi Arabia. Green-Hydrogen – Plastics-recycling

Green-Hydrogen – Plastics-recycling