Green-Hydrogen – Recycled-PP 06-08-2022 - Arhive

Green-Hydrogen – Recycled-PP

-The road to auto plastic recovery: recommendations for recycling plastics from end-of-life vehicles

Late in 2021, the Automotive Recyclers of Canada (ARC) was retained by Environment & Climate Change Canada (ECCC) to study the current practices related to the recovery of auto plastics from end-of-life vehicles (ELVs) in Canada. The purpose of the study was to develop a potential road map to contribute to Canada’s 2030 target of zero plastic waste.

In 2019, a plastics report produced by Deloitte and Cheminfo Services estimated that the auto sector produces approximately 309,000 tonnes of plastic waste annually, about 9 percent of the total amount of plastic waste worldwide. This represents the second largest sectoral producer of plastic waste after plastic packaging, which accounts for 47 percent of all plastic waste. Green-Hydrogen – Recycled-PP

About 1.6 million vehicles are retired annually in Canada, and each of these ELVs contain about 175 kg of various plastic resins. Recycling rates for the plastics in ELVs tend to be low since there are very few end markets for these materials. Plastics from ELVs are often contaminated with other plastics and metal components, and there are not currently technologies capable of recycling all of the different plastic and multi-resin parts found in vehicles.

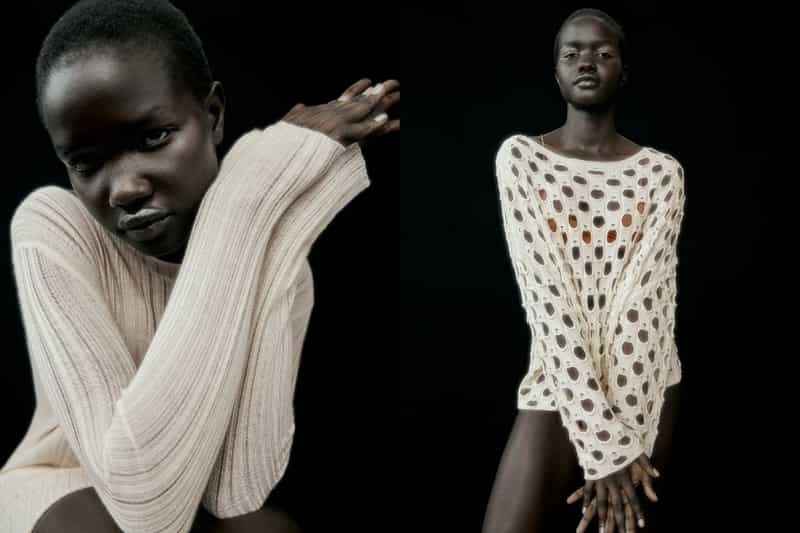

-ZARA partners with Renewcell to launch collection made from Circulose®

Zara, the global fashion brand and part of Inditex Group, is collaborating with Renewcell to create a capsule collection using Circulose®, a branded material produced entirely of recycled textiles.

A biodegradable raw material called Circulose®, created by Renewcell, is used to make textile fibers for clothing like viscose and lyocell. Circulose® fibers assist brands in limiting the use of virgin textile fibers, minimizing the climatic and environmental effects associated with the manufacturing and disposal of raw materials.

Patrik Lundström, CEO of Renewcell, said that Zara is one of the most well-known fashion companies in the world, demonstrating its ability to affect significant change within the sector. Without partners like Zara supporting this transformation, their mission to redefine fashion at scale would not come to reality through collaborations with such major brands, and their rapid development would not be conceivable. They’re excited to announce this collection created with Circulose® as the most recent development in our ongoing partnership. Green-Hydrogen – Recycled-PP

The 100% textile-to-textile recycled material Circulose® by Renewcell, which will soon begin operating at a commercial scale in their new facility in Sundsvall, Sweden, continues to divert waste from landfills by generating value through circular supply chains with brands all over the world, including now Zara.

-Machine-Side and Central Chiller Lines, Industry 4.0 Controls to Launch

Frigel will use K 2022 to showcase a number of developments in process cooling, including new and expanded lines of central and machine-side chillers, as we as advanced control platforms.

Frigel will highlight its MiND 2.0 platform, which it describe as an evolution of its Industry 4.0 offering. The company says MiND 2.0 provides a supervision and maintenance tool for all Frigel equipment and accessories, including central and machine-side chillers, monitoring and managing all working parameters and events, while tracking performance and energy consumption through a multifunctional user interface that can be accessed locally and remotely. Green-Hydrogen – Recycled-PP

Frigel has also updated its 3PR control, originally released in 2015. Designed to control its central cooling systems, Frigel says the new 3PR 4.0 platform allows processors to supervise and manage the entire cooling system from a single point. All the connected central system components are controlled via a unique control panel that has been designed specifically for Frigel systems. 3PR 4.0 is available in two versions—Lite and Premium—depending on the size of the system and the equipment to control.

-Resin Price Report: Ample Supply Meets Listless Demand With Predictable Results

As resin prices continue to slide, buyers have been floating low-ball bids to see if sellers will chase them. Some did.

The slide continues in the spot resin market, as prices for both polyethylene (PE) and polypropylene (PP) declined as July drew to a close. Overall lackluster demand is a result of ample supply and buyers’ calculations that prices have yet to find a floor, according to the PlasticsExchange.

Despite the drop in resin pricing and slowdown in activity, domestic railcar offers keep coming for both prime and off-grade materials, and the heavy flow of offers only bolstered buyers’ expectations of further declines. Green-Hydrogen – Recycled-PP

They have been floating low-ball bids to see if sellers will chase them; in some cases they do, reports the resin clearinghouse in its Market Update.

Still, the week did see some good demand from traditional spot buyers and others in need of material to fill in supply gaps partly due to logistics snafus, it added. There was also export demand from Mexico, while some domestic processors, pleased with the discounted pricing, also locked in supply through September.

The slowdown in spot trading and activity came alongside higher monomer spot levels, which began to rebound during the latter part of July. Rising monomer costs will not be enough to offset the overhang in resin supply, as suppliers have to deal with rising warehouse storage and packaging costs and brand-new resin units coming online in North America, said the PlasticsExchange. Rail logistics have improved in the West Coast, but the embargo on traffic heading into California, which was set to end in July, will continue into August.

Contract resin prices down

July PE and PP contracts were on the brink of being finalized with decreases from the June price while dismissing producer price increases in the process. The July PE contract will wipe away the $0.03/lb increase seen in May and is essentially the first true decline for contracts since December 2021. July PP, on the other hand, is on track to see its fourth consecutive monthly reduction, which will include both a polymer-grade propylene (PGP) cost decrease pass-through of $0.04/lb rather than $0.03/lb, as well as a likely margin decrease in the vicinity of $0.03/lb. Green-Hydrogen – Recycled-PP

-Hydrogen works, word from Hyundai (on trucks)

There has been a lot of discussion about the technology of hydrogen motor propulsion, with the use of fuel cells. In fact, many consider it a valid alternative to pure electric mobility, even better in some respects, but certainly the car manufacturers are investing much more in new EV models rather than Fuel Cells.

Hyundai, however, believes in hydrogen, not only for cars like the Nexo but also for heavy vehicles: thanks to a joint venture with the Swiss company H2 Energy, Hyundai Hydrogen Mobility was born, whose flagship product is the XCIENT Fuel Cell trucks. 47 of them are already on the road in Switzerland, with more than 4 million kilometers traveled in total since its launch in 2020, and now seven logistics companies in Germany are equipping themselves with these vehicles. Green-Hydrogen – Recycled-PP

As equipped with Fuel Cell technology, in which hydrogen fuel cells create energy to power an electric motor, the XCIENTs benefit from a 180 kW cell system and particularly high performance: the engine offers 350 kW (475 hp) of power and 2,237 Nm of torque “available immediately”, guaranteeing smooth and dynamic restarts even at full load.

The seven large tanks can hold up to 31 kg of hydrogen to be transformed into electricity, but as an additional stored energy source there is a set of three 72 kWh batteries. The declared maximum autonomy is about 400 km, while the time required for a hydrogen refueling is around 8 minutes and 20 seconds, depending on the ambient temperature.

Germany: the ideal market

The landing of these trucks in Germany is a sensible choice, because it is the country with the largest commercial vehicle market in Europe.

And in fact it was the German Ministry of Digital and Transport (BMDV) itself that financed the integration of 27 XCIENT on seven logistics companies in Germany, as an “extra step” towards the country’s carbon neutrality. Green-Hydrogen – Recycled-PP

Food and Beverage Giant Orders 30 Thousand Additional Shipping Pallets “Made with UBQ(TM)” and Introduces the Novel Material to Lay’s Chips Displays Across Europe

UBQ Materials, climate tech developer of advanced materials made from waste, announced today that PepsiCo is expanding its use of UBQ(TM) across its supply chain with the launch of eco-friendly Lay’s display stands, “Made with UBQ(TM),” throughout Europe.

Following PepsiCo’s successful pilot incorporating UBQ(TM) to reduce the carbon footprint of shipping pallets, the company is deepening its collaboration with UBQ in additional categories across the supply chain.

The new Lay’s Chips displays will be made in part with UBQ(TM) substituting conventional oil-based plastics.Green-Hydrogen – Recycled-PP

UBQ(TM) is a bio-based thermoplastic, made from 100% unsorted household waste, including all organics. Use of UBQ(TM) diverts waste from landfills and incineration, preventing emissions from being released into the environment. For every ton of UBQ(TM) produced, up to 12 tons of CO₂eq are prevented from polluting the environment.

Beyond the new product extension, PepsiCo has also expanded on the initial logistics pilot, ordering 30 thousand more shipping pallets made with UBQ(TM). These pallets also feature recycled PP resin and recycled BOPP – the plastic film used in the company’s snack packaging – to complete the circular economy cycle.

“Our goal is to transform our entire supply chain to tackle the sustainability challenges the world faces. UBQ Materials’ waste-based thermoplastic reduces landfill waste, prevents emissions, and takes us towards circularity, which is why we are working towards scaling use of UBQ(TM) globally,” said David Schwartz, VP, PepsiCo Labs. “We are putting sustainability and innovation at the heart of our operations.

Achieving these goals is integral to the future of our business, our customers, our consumers and the planet.” Green-Hydrogen – Recycled-PP

-Cepsa announced an agreement to develop highly efficient green hydrogen projects

Cepsa, a leading international company committed to sustainable mobility and energy, and Ohmium International, a company specialized in the design, manufacture, and deployment of PEM electrolyzers, have announced an agreement to develop highly efficient green hydrogen projects in the Iberian Peninsula, said the company.

The companies will collaborate to develop and build initially small scale projects aiming to develop a green hydrogen platform using Ohmium’s advanced modular PEM electrolyzers, with the possibility of providing Cepsa up to 300 MW of installed hydrogen production capacity. Under the agreement, the two companies will also work together on green hydrogen research and development initiatives.Green-Hydrogen – Recycled-PP

The inclusion of bold goals for green hydrogen production in Cepsa’s Positive Motion plan is an explicit acknowledgement that green hydrogen is an ideal way to decarbonize multiple industries, including complex sectors such as heavy transport, aviation, and maritime traffic. Replacing “gray” hydrogen with cost effective renewable hydrogen – no-carbon hydrogen made from water electrolysis using renewable energy sources – will be critical to meet the world’s carbon targets.

Further, green hydrogen can directly improve local and regional energy security and independence. Whereas conflicts can disrupt global energy supply chains, green hydrogen can be cost effectively produced locally where the appropriate renewable energy resources are available. Green-Hydrogen – Recycled-PP

-How2Recycle upgrades polypropylene to ‘widely recyclable’

The company’s labeling protocol applies to rigid PP tubs, bottles, jugs and jars recycled in the United States, but Greenpeace USA questions the impact of the move.

How2Recycle, the North American packaging recyclability labeling system, has announced it is upgrading the eligibility of rigid polypropylene (PP) tubs, bottles, jugs and jars from “check locally” to “widely recyclable” in the United States.

The group says it was provided data from The Recycling Partnership’s Polypropylene Recycling Coalition as well as other industry investments and notes it is “confident this progression in eligibility continues to be aligned with the Federal Trade Commission’s Green Guides.” Green-Hydrogen – Recycled-PP

“The efforts of the Polypropylene Recycling Coalition are a great example of the impact that can be made with collaborative action focused on supporting the full recycling system and we are honored to have been in an advisory role since its inception,” How2Recycle Director Caroline Cox says in a statement announcing the upgrade.

She adds, “As rigid polypropylene access, sortation and end markets are on an upward trend across the U.S., we are excited to upgrade this packaging format. … Thanks to the strength and efficacy of the national data provided, How2Recycle is confident that this change in eligibility continues to be in line with federal law,” and notes, however, the entire value chain should continue investing in improving the recyclability of all materials and packaging formats.

The milestone comes as the coalition marks its two-year anniversary. Launched in July 2020, The Recycling Partnership, based in Falls Church, Virginia, formed the coalition to bring together stakeholders across the PP value chain to improve recovery and recycling in the U.S. and further develop end markets for recycling PP.Green-Hydrogen – Recycled-PP

Green-Hydrogen – Recycled-PP