Hydrogen Automotive Chemicals 13-05-2021 - Arhive

Hydrogen Automotive Chemicals

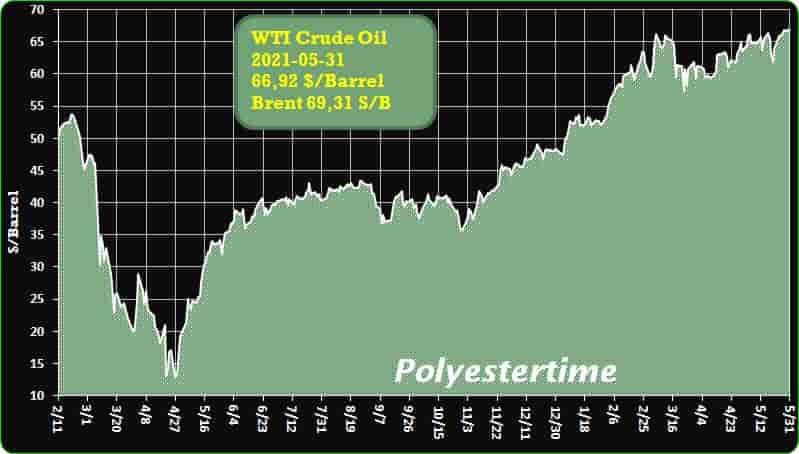

Crude Oil Prices Trend

-Closure of staple fiber operations at DAK Americas’ Cooper River Site

DAK Americas LLC (DAK) announced its plan to close the Polyester Staple Fiber(PSF) manufacturing operations at its Cooper River Site, near Charleston, SC. The site will continue to produce PET Resins to serve the bottle and packaging markets on its newer capacity installed in 2003.

The 150 Ktons per year PSF operations, which serve the Nonwovens and Textile markets, and were built more than 40 years ago, will close on December 31, 2021. The shutdown will impact approximately 200 full-service employee and 40 contract workers. Employees will be provided timely notice and a comprehensive separation package as part of the closure.

Jorge Young, DAK’s Co-President stated: “This is a very difficult decision for us. The closure of the fibers operations comes after an extensive analysis of our ability to be cost competitive in an extremely challenging market that has faced prolonged and continuing pressure from low priced imports. Current economics do not support the extensive investment needed to revitalize the site and meet future market needs.” He further added,” We thank our employees for their many years of commitment and service.”

-Polisan Holding plans to increase the loading of PET production in Greece in July

Turkish petrochemical group Polisan Holding plans to increase the capacity of PET production in Volos (Volos, Greece) to 100% in July, ICIS reported .

According to a source in the company, the renovation of the 84 thousand tons per year plant is working with a reduced load due to a lack of raw materGoogle Translate

ials.

Earlier it was reported that the petrochemical group Polisan Holding at the end of 2013 relaunched the plant for the production of polyethylene terephthalate, previously owned by the Spanish group La Seda de Barcelona, in the city of Volos, Greece. The Artenius Hellas plant with a capacity of 80 thousand tons per year, the Spanish company because of its bankruptcy was bought in September 2013 by Polisan from Ankara for EUR8.6 million. The Greek plant was renamed Polisan Hellas.

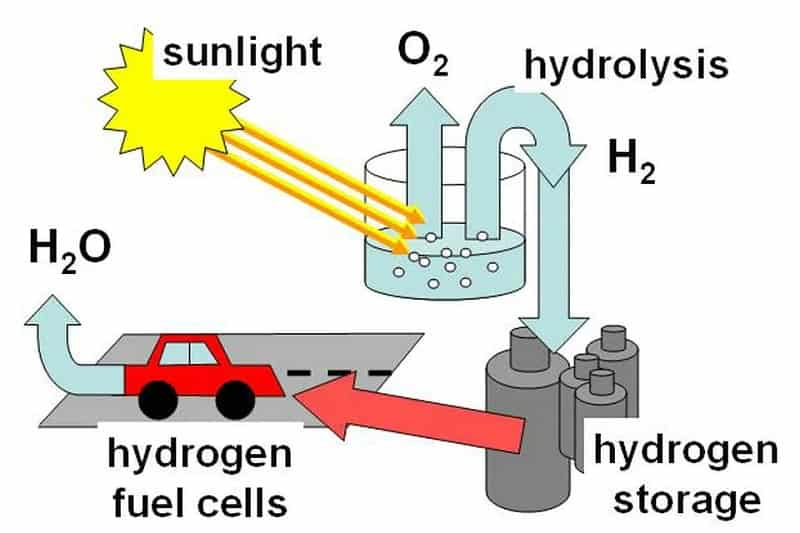

A hydrogen economy is a concept of an energy industry that uses mainly or exclusively hydrogen as an energy carrier. So far, a hydrogen economy has not been realized in any country on earth.

Like electricity, hydrogen is not a source of primary energy, but must first be obtained artificially and with energy losses from other energy sources (fossil, nuclear or renewable energies). Thus, a hydrogen economy is not automatically sustainable, but only as sustainable as the primary energy from which the hydrogen is produced. At present, this is largely done with hydrogen for use in the chemical industry on the basis of fossil fuels, Concepts for future hydrogen economies, on the other hand, mostly envisage the generation of hydrogen from renewable energies, which could make such a hydrogen economy emission-free.

While no classic state-of-the- art hydrogen economy is currently being pursued in many countries, there are plans to integrate hydrogen or hydrogen-derived fuels such as methane or methanol into the existing energy infrastructure as part of the energy transition and the expansion of renewable energies. An important role is played by the power-to-gas technology, which is assigned an important role as long-term storage.

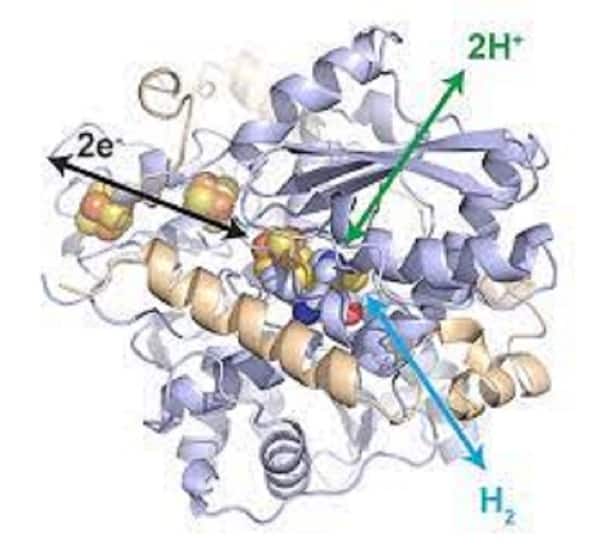

-Enzyme system for hydrogen industry

An enzyme could make a dream come true for the energy industry: It can efficiently produce hydrogen using electricity and can also generate electricity from hydrogen. The enzyme is protected by embedding it in a polymer. An international research team with significant participation of scientists from Technical University of Munich (TUM) has presented the system in the renowned science journal Nature Catalysis.

Fuel cells turn hydrogen into electricity, while electrolysers use electricity to split water to produce hydrogen. Both need the rare and thus expensive precious metal platinum as a catalyst. Nature has created a different solution: Enzymes, referred to as hydrogenases. They catalyze the conversion of hydrogen very quickly and almost without energy loss.

However, in the past these biocatalysts were not considered suitable for industrial use because of their high sensitivity to oxygen. Now a research team from the Technical University of Munich (TUM), Ruhr-Universität Bochum (RUB), the French National Centre for Scientific Research (CNRS) in Marseille and the Max-Planck Institute for Chemical Energy Conversion has succeeded in embedding the sensitive enzymes in a protective polymer in a way that makes them viable for use in technical hydrogen conversion.

-Independent role for Itemalab

New Industrial division will help other companies to digitalize their products and processes.

Itema’s Itemalab – which has been tasked with developing the weaving looms of the future at its base in Bergamo, Italy – is to become an independent company and broaden its field of activities to provide customers and partners with systems engineering and business process re-engineering skills.

The textile machinery sector is one of the most complex in the industrial world

With a team made up of 70 engineers and specialised professionals, the Textile division of Itemalab will continue to respond to the innovation needs of Itema Group and the textile industry. The new Industrial division meanwhile will assist a broad range of companies looking to develop advanced solutions for digitalizing and reshaping products and processes.

“The textile machinery sector is one of the most complex in the industrial world, due to its combination of high precision mechanical, electronic and mechatronic technologies which face very severe challenges in terms of their conditions of use, applications and productivity,” said Lorenzo Minelli, general manager of Itemalab. “Multi-disciplined know-how is one of the strong points of Itemalab, making it possible for us to offer transversal solutions and provide significant added value in terms of innovation, sustainability, digitalization and systems engineering, by transferring the know-how gained in the textile machinery world to other sectors.”

Mr. Angelo Radici Chairman of RadiciGroup -Itema’s Itemalab

-Stora Enso commits to molded pulp application

European papermaker strikes alliance with Pulpex, a molded pulp bottle technology provider.

Finland-based papermaker Stora Enso Oyj says it has joined forces with United Kingdom-based molded pulp packaging technology company Pulpex “to industrialize the production of eco-friendly paper bottles and containers made from wood fiber pulp.” Molded pulp products also can be made with recycled-content pulp.

The products to be produced “will offer an alternative to PET [polyethylene terephthalate] plastics and glass,” say the two firms. They add that their partnership “leverages Stora Enso’s formed fiber technologies and ability to convert end products at an industrial scale.”

Pulpex was established by spirits producer Diageo and and Pilot Lite, a venture management company. The partnership aims for large-scale industrial production of what it calls recyclable paper bottles and containers.

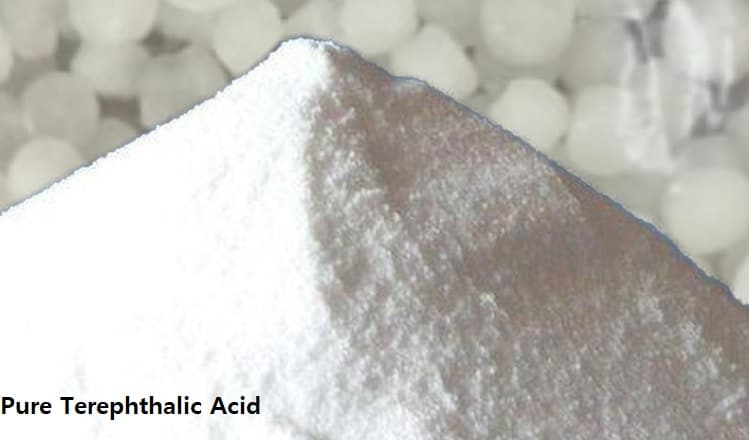

-TECHNIP ENERGIES WINS EPCC CONTRACT FOR IOCL PTA PLANT

Technip Energies (Paris) has been awarded a large Engineering, Procurement, Construction and Commissioning (EPCC) contract by Indian Oil Corporation Limited (IOCL) for its Para Xylene (PX) and Purified Terephthalic Acid (PTA) complex project at Paradip, Orissa, on the East Coast of India.

This EPCC contract covers the delivery of a new PTA plant and associated facilities. PTA is a major raw material used to manufacture polyester fibers, PET bottles and polyester film used in packaging applications. The new PTA plant’s capacity will be 1.2 million metric tons per year (m.t./yr).

Marco Villa, Chief Operating Officer of Technip Energies commented: “We are pleased to be awarded another prestigious contract by Indian Oil Corporation Limited. We look forward to starting this significant project which illustrates our commitment to India – a core market for us. It also significantly consolidates our leading position for executing complex petrochemical projects.”

-Devan launches bio-based softener and quick-dry finish to support Circularity programmes

Textile innovator Devan Chemicals recently added two more products to its range of bio-based textile finishes. One being a softener, the other one a quick-dry finish. Both are derived from vegetable oils and are in line with the company’s latest innovations on bio-based chemistry.

The Covid-pandemic is serving as an accelerator for a worldwide green economy, thanks to both changing consumer behaviour and government action. 84% of EU consumers find sustainability important, reports Insites Consulting in its latest Conscious Consumptions Study. This figure is a clear increase compared with pre-pandemic results.

As a result, the world in general and the textile industry in particular are increasingly seeking more sustainable and products fit-for-circular programs.

-UK textile firm C&C expects 40% productivity boost with Made Smarter

Cookson & Clegg (C&C), a UK textile manufacturer, is expecting a 40 per cent productivity increase, greater efficiency, less waste, and more profit, after investing in technology support by the Made Smarter North West Adoption programme. Made Smarter is an industrial digitalisation movement to drive productivity and growth of manufacturing industries.

Over its 160 year history, Cookson & Clegg (C&C), based in Blackburn, has gone from producing leather products and manufacturing military apparel to premium brand clothing and protective wear such as medical scrubs, gowns, and reusable face coverings.

C&C is now embarking on a major data and systems integration project which will capture real-time data from every part of the production process and enable the leadership team to make informed decisions to identify efficiencies, generate more accurate pricing, and increase profitability, according to a press release by Made Smarter.

-Danimer Scientific Receives Innovation Research Grant to Support Biodegradable Plastic Solutions

Danimer Scientific and the University of Minnesota’s Forever Green Initiative will research pennycress oil as a potential feedstock material for producing polyhydroxyalkanoate (PHA), a biodegradable, eco-friendly alternative to traditional plastic.

Danimer Scientific , a leading developer and manufacturer of biodegradable materials, today announced it has received a Small Business Innovation Research (SBIR) grant to research pennycress oil as a potential feedstock material for producing polyhydroxyalkanoate (PHA), a biodegradable, eco-friendly alternative to traditional plastic. Danimer Scientific will partner with the University of Minnesota’s Forever Green Initiative starting in July 2021 to research the potential for using pennycress oil in producing the company’s Nodax® biodegradable solution.

The project will help determine whether pennycress oil can serve as a viable alternative to supplement the company’s current use of canola oil as a feedstock. Researchers will also compare pennycress oil sourced from wildtype seeds with plants domesticated as winter cover crops.

Results will guide the development of commercial models for using pennycress oil to produce PHA, a material manufacturers need to make biodegradable drinking straws, cutlery, packaging and other single-use products.

Hydrogen Automotive Chemicals