Hydrogen cars – Rigid film 05-05-2023 - Arhive

Hydrogen cars – Rigid film chemical recycling – bio-material

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Borealis has launched Stelora, a revolutionary new engineering polymer that offers exceptional performance and sustainability benefits.

Stelora is a sustainable alternative to conventional engineering polymers and is produced from renewable feedstock, making it a vital contributor to a circular economy.

This new material is suitable for a range of advanced applications requiring high-temperature polymers, making it an essential tool in the transition to renewable energy and e-mobility.

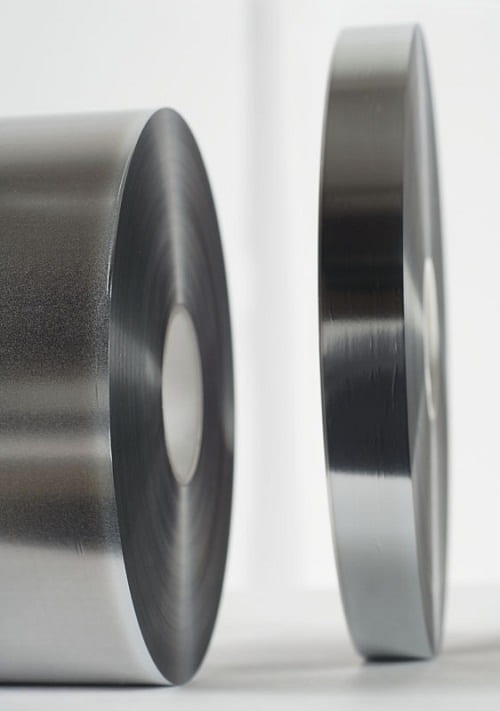

The first commercial application of Stelora is in a high-heat-resistant capacitor film that delivers superior performance compared to traditional films made with polypropylene (PP). Stelora-based films offer exceptional heat resistance, electrical properties at high temperatures, and increased efficiency. chemical recycling – bio-material

They are fully compatible with existing converting lines, making them easy to process without the need for investment in new equipment or infrastructure.

Stelora’s performance benefits include its ability to close the product performance gap between polyolefin-based polymers and high-temperature engineering plastics.

This means that heat-resistant capacitors made with Stelora degrade more slowly, reducing the need for frequent replacement, making them ideal for use in offshore wind installations. Hydrogen cars – Rigid film

As they can tolerate higher temperatures, less space is required for cooling, reducing the size and construction cost of inverters.

The same mechanism enables the production of smaller and more energy-efficient final products, including electric vehicles.

Stelora’s sustainability benefits are equally impressive. Its use of renewable feedstock allows customers to achieve their sustainability targets and support the transition to a circular economy, in line with Borealis’ EverMinds(TM) mindset.

The company’s commitment to sustainability is evident in its alignment with the UN Sustainable Development Goals and the European Green Deal.

Borealis is proud to launch Stelora, a transformative material solution for capacitor film that combines exceptional performance with significant sustainability advantages.

The company is exploring how Stelora’s many advantages can be extended to other high-performance applications in different sectors, offering a circular way to reinvent essentials for sustainable living. Hydrogen cars – Rigid film

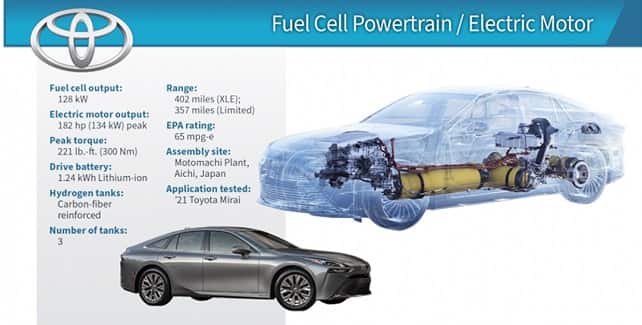

-Hydrogen? For Toyota, it is still a big yes.

During the Let’s go Beyond event, the Toyota Group in Italy illustrated its multi-technological approach towards energy transition and complete carbon emission neutrality by 2040. This represents a continuation of the company’s long-term environmental sustainability strategy launched in 2015, the Toyota Environmental Challenge 2050, aimed at ensuring a concrete commitment to environmental protection and sustainable mobility in line with the Sustainable Development Goals of the United Nations. The company’s goal is to limit the impacts of its business on the environment by monitoring and acting throughout the entire value chain. chemical recycling – bio-material

“In Toyota, we believe that winning the challenge of achieving carbon neutrality is fundamental to ensuring a prosperous future for our planet. As a leader for 25 years in the field of electrification, we have always demonstrated extraordinary commitment in imagining and developing what is necessary to meet this challenge.

This is achieved through our constant contribution to the realization of a sustainable and inclusive society, thanks to innovative and electrified mobility solutions and new services, to allow everyone to move without barriers and limitations, in total safety and respect for the environment, without leaving anyone behind,” said Luigi Ksawery Luca, CEO of Toyota Motor Italia. Hydrogen cars – Rigid film

This commitment is realized in the vision called “Let’s Go beyond,” in which the goal of zero emissions represents only an intermediate stage towards a future in which moving around makes the world a better place. This is further reinforced by the strategy on battery-electric vehicles, which today represent one of the most promising options for achieving carbon neutrality.

Furthermore, a fundamental element of this vision is the use of hydrogen, which embodies the ambition to go “beyond” zero emissions and to contribute not only to building a better world but also to producing happiness for everyone, thanks to the better use of this important energy vector. chemical recycling – bio-material

Continuous innovation remains a fundamental characteristic of Toyota’s products and services, allowing the company to increase the offering of benefits it provides to customers. Hydrogen cars – Rigid film

“An expression of this drive towards innovation is the WeHybrid ecosystem which, thanks to the joint commitment of all Toyota companies in Italy, is enriched with new elements, gaining success in the market but, above all, transforming the customer into a true ambassador of the technology of our electrified vehicles, as a witness to the concrete benefits that arise from a virtuous use of our electrified solutions,” said the CEO.

Another pillar of the “Let’s Go Beyond” vision that embodies Toyota’s ambition to continue its transformation into a “Mobility Company,” ensuring full freedom of movement for everyone without barriers and limitations, in total safety and respect for the environment, is represented by the KINTO brand. “KINTO represents the Toyota Group’s challenge in the transformation towards a Mobility Company, thanks to innovative mobility solutions in a continuously evolving context. To win this challenge, it is essential to place people at the center, understanding the new mobility needs with the aim of producing positive externalities for everyone, resulting from a virtuous combination of electrified technologies and mobility platforms. KINTO is a concrete example, the affirmation of a value system that translates into a range of services for individuals, companies, communities, and institutions. chemical recycling – bio-material

The KINTO vision envisages the creation of an open mobility ecosystem, synonymous with inclusive and reliable, simple and intuitive, as well as sustainable, with the aim of enabling easy and fast movement for everyone, without leaving anyone behind,” said the CEO of Toyota Financial Services Italy and the President and CEO of KINTO Italy. Hydrogen cars – Rigid film

-Does the Plastics Tax UK open up to chemical recycling?

The UK government has launched a public consultation to consider whether to use mass balance to calculate recycled content for exemption purposes.

plastics tax UKPlastic Packaging Tax (PPT) came into effect last year, charging £200 for every tonne of plastic packaging manufactured in the country or imported, excluding plastics containing more than 30% recycled material by weight, semi-finished products and some specific types of packaging. chemical recycling – bio-material

The British government is now evaluating whether to assimilate chemical recycling to mechanical recycling, through the attribution to plastics of feedstock from chemical recycling instead of fossil raw materials, to be implemented through mass balance certified by third parties. To this end, it has launched a public consultation, inviting operators in the sector to express themselves on the subject before making a decision.

With this opening, the authorities would like to promote investments in the most advanced forms of recycling, such as chemical recycling, aimed at recovering the fraction of “difficult” waste, which mechanical recycling is unable to intercept for technical or economic reasons. Hydrogen cars – Rigid film chemical recycling – bio-material

The proposal has been welcomed by the British plastics supply chain association, the British Plastics Federation (BPF), who believe the mass balance approach is a valuable tool for maximizing the amount of plastic recycled in the UK. According to the association, greater clarity is needed to unlock investments in chemical recycling, to be considered complementary to mechanical recycling, preventing them from being channeled abroad.

-Energy savings come with a film

A new discovery, a cellulose-based film, could revolutionize building air conditioning. This new discovery would also be environmentally friendly, as it would not require the use of electricity, representing a significant long-term energy and economic savings. So, no air conditioners, but only the biological exploitation of a substance, which is also revised in the “light” of the laws of physics. It may seem like a pun, because, in fact, at the center of the discovery, there is sunlight and heat. Hydrogen cars – Rigid film chemical recycling – bio-material

This new cellulose-based film is the result of a project conducted by Silvia Vignolini, director of the Sustainable and Bio-inspired Materials department of the Max Planck Institute and professor of Chemistry and Bio-materials at the University of Cambridge, together with a colleague from Purdue University. The research focused on “passive diurnal radiative cooling,” which exploits the qualities of materials, sunlight, and infrared bands. This led to the development of a colored film, a few microns thick, that can cool a surface exposed to sunlight by 3°C. The colored film does work, energetically and physically speaking, and therefore saves electricity, as it is not powered by anything except chemical-physical phenomena.

“It is structurally very stable and since I was working on pigments with reduced environmental impact – paint chemistry is usually quite dirty – I thought the combination would be perfect. We obtained a coating less than 10 microns thick that allows for temperature reduction using only cellulose. Of course, we are not yet ready to coat entire buildings, there are many small problems before this technology can be used; surfaces must remain clean and must be tested in the presence of different atmospheric agents. But we are working on it, and I am confident.” Hydrogen cars – Rigid film

To understand better, it is enough to analyze how these physical elements work. The alternation of seasons depends on how sunlight and solar heat arrive on Earth in different months of the year, in addition, of course, to the variables introduced daily by the weather and, unfortunately, in general, by climate change.

Light and heat arrive perpendicularly to the equator during the spring and autumn equinoxes, while they do the same on the Tropic of Cancer for the summer solstice and on the Tropic of Capricorn for the winter solstice. This means that in summer, in the northern hemisphere, one of the reasons why it is hotter is precisely this direct way of emitting light and heat from the Sun. chemical recycling – bio-material

Light and heat react differently based on colors; for example, white reflects light and heat, while black absorbs them. This happens because white operates by additive synthesis of all colors, black by subtractive synthesis. The quality of colors to absorb or reflect light and heat differently, which today is studied within the infrared region, is actually empirically known since ancient times. Just think of white houses in some parts of the world, used to exploit the Sun in a defensive or climatic way. Hydrogen cars – Rigid film

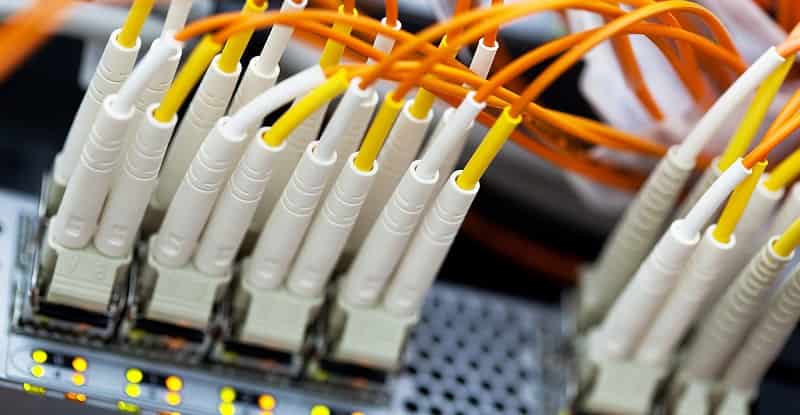

-Ineos produces ultra-thin, rigid film for recyclable flexible packaging

The new packaging film contains 50 percent recycled plastic.

Ineos, a global petrochemicals manufacturer headquartered in London, has produced an ultra-thin, rigid film for recyclable flexible packaging applications made from 50 percent recycled plastic.

According to a news release from Ineos, the company partnered with Germany-based Hosakawa Alpine to use its machine-direction orientation (MDO) technology to process what it calls Recycl-IN resins, which contain 50 percent recycled plastic to make polyethylene film. Ineos says this new film will be used to manufacture recyclable, single-polymer flexible packaging products that replace hard-to-recycle multimaterial packaging products. Hydrogen cars – Rigid film chemical recycling – bio-material

Ineos has invested in a Hosakawa Alpine MDO film line to develop its flexible packaging films made from a single polymer family, which Ineos says increases the recyclability of plastic packaging. Ineos says this packaging solution can help to ensure more packaging contains recycled materials and can be recycled in the future.

Recycl-IN resins also are certified as providing a 25 percent to 50 percent reduction in carbon emissions when compared with the use of virgin feedstocks, Ineos says.

“We share people’s concerns about plastic waste, showing we can help produce more recyclable end products using large quantities of recycled materials,” says Rob Ingram, chief executive of Ineos O&P Europe North. “Now that we’ve proved the concept, we open the door to exploring the application of Recycl-IN and MDO technology to other flexible packaging products where we can make a real difference.” Hydrogen cars – Rigid film

-Sabic has added upcycled flame-retardant PBT resin to its portfolio of iQ compounds, called LNP Elcrin WF0051iQ

The compound contains at least 27% recycled PET water bottles, diverting post-consumer waste and reducing the carbon footprint. chemical re cycling – bio-material chemical recycling – bio-material

It has an 11% smaller carbon footprint than standard, fossil-based virgin PBT resin.

The compound’s thin-wall, non-brominated/non-chlorinated flame retardance makes it ideal for miniaturized electrical components, medical devices, and appliance applications.

LNP Elcrin WF0051iQ meets the UL94 V0 standard for fire resistance and has a high flow rate, low abrasion properties, and glass-fiber reinforcement for stiffness, enabling complex geometries. Hydrogen cars – Rigid film

The material also supports safety and reduced material requir chemical recycling – bio-materialements, lowering tooling costs and accelerating time to market.

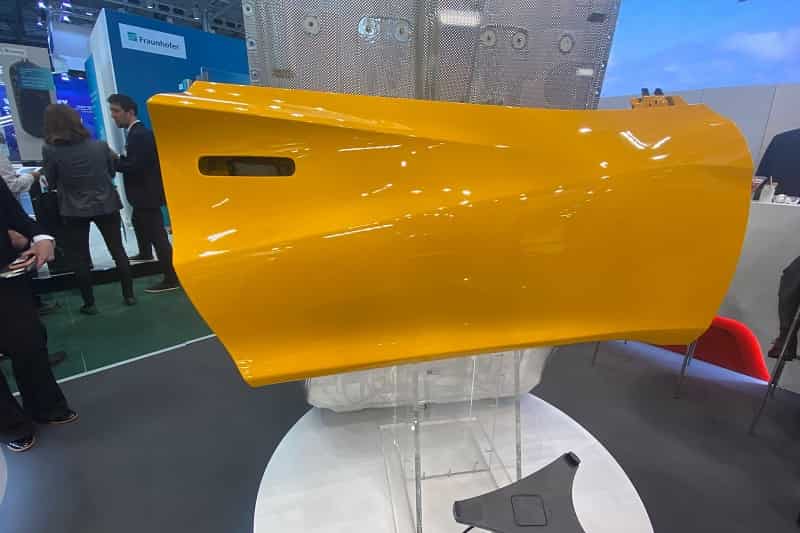

-Teijin Supplies Eye-Catching Exterior Components of New Lotus Emira

The panels are compression molded using Teijin Automotive Technologies’ TCA Ultra Lite material, which is up to 43% lighter than traditional composites.

If you’ve seen the all-new Lotus Emira, the dramatic exterior styling probably caught your eye. The sleek exterior of this mid-engine premium sports car is made possible, in part, by the advanced composite exterior panels provided by Teijin Automotive Technologies. Specifically, Teijin is providing the right- and left-hand doors; right- and left-side rear quarter panels; and the inner, outer, and lower shells of the tailgate.

The doors, rear quarter, and tailgate outer panels are manufactured using the company’s proprietary TCA Ultra Lite material. Hydrogen cars – Rigid film chemical recycling – bio-material

This low-density, Class A surface material is up to 43% lighter than a traditional composite material — approximately the same weight as aluminum. However, because it is a compression-molded composite, it can achieve dramatic styling cues not possible with a stamped metal, and it is dent- and corrosion-resistant. This material is being produced on the company’s state-of-the-art sheet molded compound (SMC) line in Pouancé, France.

Teijin Automotive Technologies’ Ultra Lite uses proprietary treated glass bubbles to replace some of the calcium carbonate (CaCO3), allowing the resin to adhere to the matrix and increase the interfacial strength between the bubble and resin.