Hydrogen Petrochemicals PlasticPollution 09-07-2021 - Arhive

Hydrogen Petrochemicals PlasticPollution

Crude Oil Prices Trend

-What is the EU Single-Use Plastics Directive?

We are in the middle of a plastics crisis, and action is required to curb the damage our handling of this resource is having on our environment. In Europe alone, more than 25 million tons of plastic waste are generated every year, yet less than 30 percent of such waste is collected or recycled, and 85 percent of marine pollution is said to be plastic waste. Plastic waste exports to Turkey, Malaysia, Vietnam, Thailand, and Indonesia from EU countries continued at high levels in 2020.

The 2018 EU Plastics Strategy outlined the need for a legislative proposal on single-use plastics, to target reductions in plastic leakage to reduce its impact on the environment and on human health. The European Union focused on the 10 most commonly found plastic items littered in European coastal areas. After evaluating the potential pathways towards reduction, the EU passed in 2019 what has become known as the Single-Use Plastics Directive (SUPD). Hydrogen Petrochemicals PlasticPollution

Masotina has partnered with ZenRobotics to retrofit their plastics sorting facility (PRF) with an AI-powered robotic sorting station for the recovery of clear PET at a high purity rate.

The Masotina plant in Milan, Italy, is a household waste plastic recovery and sorting facility with a total capacity of 355,000 tons per year. The facility has been retrofitted in recent years to include sophisticated recycling automation technologies to separate out recyclable waste plastics. Hydrogen Petrochemicals PlasticPollution

Masotina’s facility is one of the largest material recovery facilities (MRF) in Europe that receives, sorts, separates and prepares recyclable household waste plastics. By partnering with ZenRobotics, Masotina expands its technology leadership to include AI-based waste sorting robotics at its flagship facility.

The facility separates household waste plastics coming mostly from municipal collection. Plastic waste is first sorted from other valuable recyclable materials like paper, cardboard, aluminum, tinfoil, polylaminates and inert. It is then separated by polymer and colour to maximize the recycle-reuse value of plastic.

-Coca-Cola to manufacture 100pc rPET bottles in UK

Global beverage company Coca-Cola will use 100pc recycled polyethylene terephthalate (rPET) to manufacture all plastic bottles of 500ml or less from September 2021 in the UK. Hydrogen Petrochemicals PlasticPollution

The company estimates the move — which will affect all Coca-Cola beverages and other brands in its portfolio such as Fanta, Sprite and Dr Pepper — will reduce virgin plastic use by 29,000 t/yr.

The need for more sustainable solutions has been rising in recent years. More companies have been stepping up plastics sustainability efforts given increasing environmental pressure to reduce plastic waste. Coca-Cola recently signed the Anzpac Plastics Pact that aims to eliminate plastic waste in Australia, New Zealand and the Pacific Islands by 2025.

Global beverage company Coca-Cola will use 100pc recycled polyethylene terephthalate (rPET) to manufacture all plastic bottles of 500ml or less from September 2021 in the UK.

The company estimates the move — which will affect all Coca-Cola beverages and other brands in its portfolio such as Fanta, Sprite and Dr Pepper — will reduce virgin plastic use by 29,000 t/yr.

The need for more sustainable solutions has been rising in recent years. More companies have been stepping up plastics sustainability efforts given increasing environmental pressure to reduce plastic waste. Coca-Cola recently signed the Anzpac Plastics Pact that aims to eliminate plastic waste in Australia, New Zealand and the Pacific Islands by 2025.

As one of the leading bottled water producers in Iraq, Durrat Al Khaleej aims to provide the best experience to consumers. Sidel’s packaging solutions successfully fulfilled its goal by delivering a complete water line with a lightweighted and simultaneously stable PET bottle design, weighing only 10.5 grams for the 500 ml bottle format, at a time of very high travel restrictions in Iraq.

Durrat Al Khaleej, established in 2007, has become familiar to consumers as a symbol of good-quality water in Iraq. Hydrogen Petrochemicals PlasticPollution

The company is adapting advanced production technology not only to adhere to national and international regulations and standards, but also to stay at the forefront of innovation and sustainability. Ensuring the highest levels of quality and safety throughout the supply chain, from raw materials to the point of consumption, Durrat Al Khaleej has a laboratory that systematically checks the water produced to ensure it meets stringent standards to achieve its ambition for progress and development in Iraq.

Lightweight and stable PET bottle design and cost-effective line solution

To optimise bottle design as well as line performance, Durrat Al Khaleej chose Sidel for its expertise in packaging solutions. The collaboration between Sidel and the customer was crucial to develop a new PET bottle design and to manage the installation and commissioning of the equipment, as the site for the line was a greenfield project. After the meeting in Dubai, Sidel’s packaging experts met the customer’s expectations by proposing the lightweight solution, while also incorporating the original premium look. The lightweight PET bottle in the 500 ml bottle format, weighing only 10.5 grams, has high stability and has proved to be very successful on the market. In light of its sustainability and low total cost of ownership (TCO), Sidel’s complete water line has become the perfect solution, with a speed of 24,000 bottles per hour (bph) for 500 ml. It has not only helped the customer save water on bottle cleaning, but also no air conveyer is needed.

-The EU’s new directive on single-use plastics could stifle innovation

There has been plenty of discussion about how legislation – or lack thereof – can hinder the emergence and widespread use of solutions that can solve some of the most difficult challenges of our times. With enough resources, technology and innovation can be developed fast, but legislation often falls behind and it can take years for lawmakers to catch up. Hydrogen Petrochemicals PlasticPollution

By this July 3, the member states of the EU should have implemented the new Directive on Single-Use Plastics that bans nine plastic products, such as single-use straws and cutlery, often found littering the beaches of Europe. The aim is certainly noble: to prevent and reduce the impact of these plastic products on the environment and on human health.

The directive is also meant to serve as a step towards a circular economy with innovative and sustainable business models, products and materials – all geared towards more efficient use of our planet’s limited resources, so that we can protect and maintain our world for future generations.

Sadly, due to the way the Directive defines plastics, it can prove to be a difficult obstacle to innovative, sustainable solutions aimed at saving the world from plastic waste.

The directive defines all synthetic polymers (e.g. fossil-based polymers) and all chemically modified natural polymers as plastics, so that this definition now also includes bio-based biodegradable and compostable plastics products – even though many of those products could help us fight plastic pollution by offering effective solutions.

-‘Interest and opportunity’ for an automotive circular economy

ACC has met with more than 30 congressional offices and is “advocating strongly … for R&D and federal funding that is going to help enable sustainable automotive solutions,” Gina Oliver said, adding that it is seeing broad support from Congress.

Automotive suppliers can reach out to their members of Congress and research and development groups to engage on sustainability goals as the industry moves toward a circular economy. Hydrogen Petrochemicals PlasticPollution

“With the infrastructure package … and the goals of the [Joe Biden] presidential administration in this space, there’s a lot of interest and opportunity in automotive, I think more than ever,” Gina Oliver, senior director of the American Chemistry Council’s automotive plastics division, said during Plastics News’ Plastics in Automotive virtual conference on May 27.

ACC has met with more than 30 congressional offices and is “advocating strongly … for R&D and federal funding that is going to help enable sustainable automotive solutions,” Oliver said, adding that it is seeing broad support from Congress.

“They’re really interested in knowing what we’re doing in this space and how they can help us,” she said. “They want the low carbon future to be more circular. … They’re very eager, on both sides of the aisle … [in] supporting solutions that are sustainable,” like nationwide charging infrastructure, pushing the industry toward electric battery manufacturing.

While ACC can help suppliers find direction in where to look for collaborations and R&D funding for circularity efforts, it also encourages suppliers to reach out to other groups and start conversations.

The U.S. Department of Energy’s REMADE program has provided about $43 million for U.S. manufacturers to increase the recovery, reuse and remaking of manufacturing of plastics and other materials.

-TOMRA study – Holistic resource systems could save 2.76 billion tonnes of CO2

The United Nations Sustainable Development Goals (SDGs) of 2016 have been concretised by the European Commission: The new EU climate law increases the emission reduction target from 40% to at least 55% by 2030 to meet the expectations of the November World Climate Summit in Glasgow. As an innovation leader, TOMRA aims to help achieve the goals and take waste management to another level. A new study commissioned by TOMRA and conducted by EUNOMIA demonstrates the potential for an optimized waste management system as regards to climate change. Overall, a reduction of 2.76 billion tonnes of CO2/year is possible.

This reduction can be achieved using Holistic Resource Systems – the optimized combination of key waste management practices for collection, sorting and recycling to facilitate the transition toward a circular economy, which is preventing resource depletion, reducing littering and contributing to a carbon neutral world.

Holistic resource systems are an ideal combination of political framework regulations, such as extended producer responsibility, deposit return schemes, and technical processes for waste handling. London-based consultancy for sustainability Eunomia, has examined various models to identify the most efficient, cost-effective scenario for a holistic system. Hydrogen Petrochemicals PlasticPollution

-Chemical Recycling: Can University Labs Succeed Where Privately Held Startups Continue to Struggle?

Many good technologies come out of university labs, but it’s questionable that research into chemical recycling, which has been ongoing in the private sector for up to three decades, will bear fruit.

Since the start of the year, I’ve gotten several announcements from various universities about advances in new technology. An article that was published in PlasticsToday on Feb. 10 reported on a development at the Chirik Lab at Princeton University. Paul Chirik, the Edwards S. Sanford Professor of Chemistry, called the newly discovered recycling process “the most important thing ever to come out of my lab.” Hydrogen Petrochemicals PlasticPollution

Other universities are also working on chemical recycling technologies to help solve the problem of difficult-to-recycle plastics, including the University of Oklahoma and the University of Wisconsin-Madison in collaboration with Case Western Reserve.

In March, the US Department of Energy (DOE) awarded UMass Lowell researchers $1.8 million to develop recyclable plastics and manufacturing technologies to help the country reduce greenhouse-gas emissions and improve environmental sustainability. The grant is funded through the REMADE Institute, a public-private partnership created by the DOE to help the United States move toward a circular economy. The UMass Lowell project will seek ways to improve the recycling of plastics from industrial and consumer goods that typically end up in landfills.

Industry partners working with UMass Lowell on the project include SER North America LLC, a material supplier that focuses on sustainable plastics, along with iMLFUX Inc., a Procter & Gamble company that develops injection molding innovations in support of sustainable manufacturing. The collaboration will provide UMass Lowell engineering students opportunities to work closely with engineers at the partner companies. Hydrogen Petrochemicals PlasticPollution

On April 21, Science Daily ran an article about research at the University of California, Berkeley, and University of Massachusetts Amherst, funded by the US Army Research Laboratory, that involves embedding polyester-eating enzymes in plastic as it’s made, a process that promises to eliminate microplastics.

Memorandum of Understanding outlining terms of Joint Venture to build Infinite Loop™ facilities in Asia Hydrogen Petrochemicals PlasticPollution

Equity investment of $56.5 million will be used by Loop towards funding its planned Canadian Infinite Loop™ facility in Bécancour, Québec

SK global chemical to become second largest shareholder

Loop Industries to hold corporate update call at 11:30am Eastern Time today

Loop Industries ) (“Loop” or “The Company”), a leading innovator in clean technology whose mission is o accelerate a sustainable plastics economy, today announced that it intends to form a strategic partnership with SK global chemical Co. Ltd. (“SKGC”), a subsidiary of South Korea’s SK Group, one of Asia’s largest conglomerates, to accelerate the commercialization of Loop’s sustainable polyethylene terephthalate (“PET”) plastic and polyester fiber manufacturing technology throughout Asia.

Loop’s patented technology allows for waste PET plastic and polyester fiber to be upcycled into virgin-quality PET using low heat and no added pressure. This low energy process allows Loop to eliminate contaminants, such as dyes, additives, and other impurities, preventing otherwise unrecyclable materials like colored and contaminated plastics or textiles from ending up in landfills and natural areas.

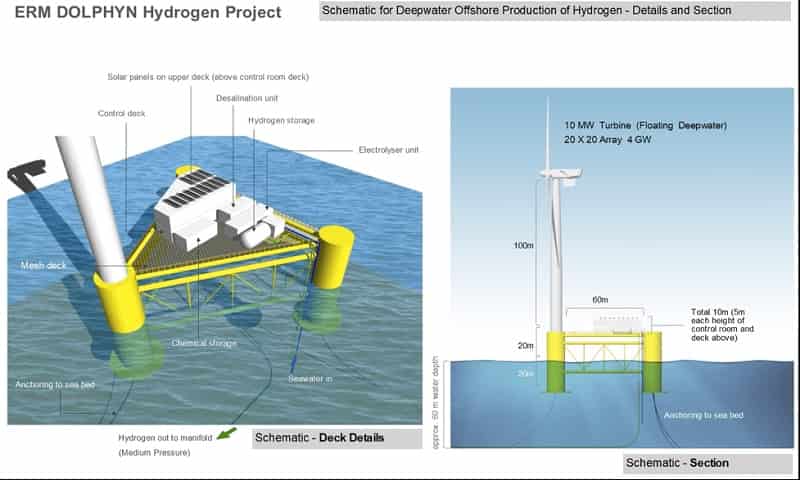

-Dolphyn hydrogen project accelerates to next phase

The ERM Deepwater Offshore Local Production of Hydrogen (Dolphyn) project is progressing to its next phase of development, supporting up to 100-300MW of offshore-wind-powered electrolysis within the 2020s, project developers ERM confirmed to ICIS on 2 July. Hydrogen Petrochemicals PlasticPollution

The ERM Dolphyn project aims to produce hydrogen from floating offshore wind, using electrolysers located on the turbine platforms, therefore avoiding power connections and transporting hydrogen molecules to shore.

Over the last 12 months ERM has been developing the design of a 2MW Dolphyn prototype unit. However, the project is now accelerating as a result of sufficient de-risking, with ERM now moving to develop a 10MW commercial demonstrator project offshore of Aberdeen, Scotland, ERM told ICIS.

“We are wrapping up PRE-FEED [front-end engineering design] on that [the 10MW demonstrator] at the moment and hope to move to FEED in September 2021, completing this in autumn 2022 when a final investment decision on this 10MW project will be made,” ERM said.

Initially the project’s 2MW prototype unit was expected to move into operation by 2024 with the planned 10MW unit installed by 2027.

Hydrogen Petrochemicals PlasticPollution