Hydrogen – PVC – rPET – Recycling 08-12-2022 - Arhive

Hydrogen – PVC – rPET – Recycling

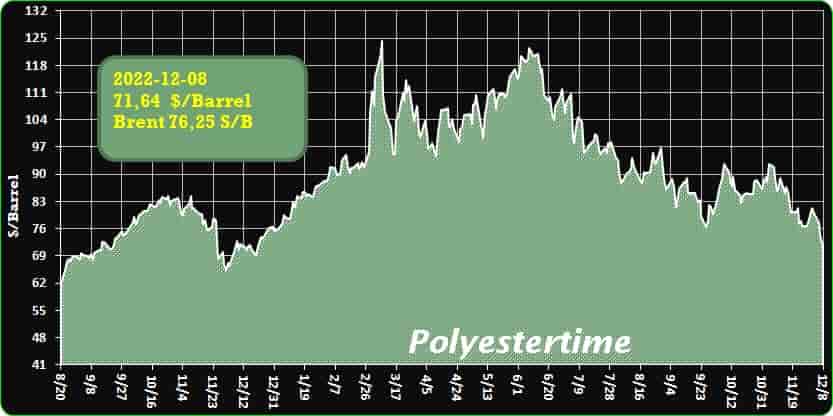

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Starlinger viscotec – Doubling rPET manufacturing capacity: Evergreen, USA

Established in 1998 with a single location in Clyde, Ohio, Evergreen is a recycling company and one of North America’s largest producers of food grade rPET.

Now, Evergreen has the capacity to process 217 million pounds (108,500 tons) of post-consumer food-grade rPET per year across its four facilities located in the US and Canada.

Evergreen supplies global brands with their recycled resins, that use these for products like beverage bottles, food containers, health and beauty packaging, home products, rPET fiber, and strapping. Evergreen has observed a growing consumer demand for rPET in various products, which has therefore led the rPET producer to make major investments to expand its Clyde, Ohio plant. ”We hold the key to meeting those demands by being one of the largest preprocessors in North America and soon the globe.”

Doubling rPET manufacturing capacity

Evergreen completed the expansion of its building in Clyde, Ohio in summer 2022. The expansion was the first step of significant growth for Evergreen. The company doubled its rPET pellet manufacturing capacity at the Ohio facility and now has a local capacity of 113 million pounds (56,500 tons) of food grade PET per year.

“Our goal is to continue to grow to become a global leader in PET recycling. The expansion in Clyde started with the installation of two solid state polycondensation reactors by viscotec and a Starlinger bottle-to-bottle recycling line. That quickly grew to include a second Starlinger bottle-to-bottle line.” says Omar Abuaita, CEO of Evergreen, about the scope of the extension in phase 1. Phase 2 is already being planned, according to Abuaita. “The demand for rPET is very strong in the Midwest and the Clyde facility will continue to grow to meet our customers’ needs.”

-Green Hydrogen Truck Means Zero CO2 Emissions for INEOS Inovyn PVC Deliveries Between Tavaux and Dijon

60 tonnes of CO2 will be saved every year when INEOS Inovyn brings its new Hydrogen truck into service to deliver PVC from its production plant in Tavaux to Benvic’s PVC compound plant in Dijon. From April 2023, this carbon dioxide emissions from the deliveries will be reduced to zero.

To make this possible, INEOS Inovyn partnered with Benvic and leading industrial logistics company GCA Trans Service to produce a new hydrogen-powered truck. The new truck will be built based on a DAF chassis in which the diesel motor will be replaced by hydrogen fuel cells. Hydrogen – PVC – rPET – Recycling

The truck, which will be refueled at a local station in Dijon providing 100% green hydrogen, has a range of 500 km between two refills.

Geir Tuft, CEO of INEOS Inovyn, said:

“This is a historical moment for our company.

“The use of hydrogen trucks for product deliveries is a key part of our sustainability roadmap which aims to drastically reduce our CO2 footprint over the next few years. The Tavaux truck will be leading the way, and we have already planned similar projects with other customers in Benelux.”

Luc Mertens, CEO of Benvic, said:

“This initiative between BENVIC and INEOS Inovyn is a perfect fit with all our ESG actions, and also improves the environmental performance of our product.

“We work continuously to innovate our range of sustainable compounds in every way and logistics is a key factor so we very proud to be one of the first INEOS Inovyn partners to engage in hydrogen-based technology for our deliveries.”

All customers and partners are welcomed to join the initiative and work together with INEOS Inovyn to ensure CO2-free deliveries across sites.

Geir Tuft, CEO of INEOS Inovyn, says:

“Supplying hydrogen to the transport market is a key step in our new INEOS Hydrogen business strategy which also includes new hydrogen production from water electrolysis, as well as hydrogen storage and development of downstream supply into chemicals.

Highlights:

- INEOS Inovyn is to become the first company in Europe to use a hydrogen truck for PVC transportation. The new truck was presented at this year’s INOVYN Awards ceremony on 20 October.

- Deliveries with the new truck will begin at the end of Q1 2023, from INEOS Inovyn’s PVC production plant in Tavaux to Benvic’s plant in Dijon.

- It is expected that 60 tonnes of CO2 emissions will be saved each year thanks to this initiative.

- Similar projects are already foreseen in the Netherlands and Belgium.

Green Hydrogen truck means Zero CO2 emissions for INEOS Inovyn PVC deliveries between Tavaux and Dijon, December 5, 2022 Hydrogen – PVC – rPET – Recycling

-Contract prices of PE in the US in November remained unchanged

U.S. polyethylene (PE) contract prices remained unchanged in November for the second month in a row,according to ICIS.

Domestic spot prices remained largely stable from the previous month, with spot product availability being lower from the previous month as manufacturers used inventories for the past two straight months.

Lower costs for ethane and natural gas led to lower production costs for producers compared to the previous year, easing margin pressures for polyethylene producers.

Contract PE prices in November were estimated at 70–92 cents per pound for high-pressure polyethylene (LDPE), 63–87 cents per pound for linear butene-based low-density polyethylene (LDL C4), and 66–86 cents per pound for blow molding of low-pressure polyethylene (HDPE), DEL USA. Hydrogen – PVC – rPET – Recycling

Earlierit was reported that november contract prices for ethylene in the US rose against the background of a slight increase in spot prices. The November contract price rose 0.25 cents per pound (USD5.51 per tonne) from October to 34 cents per pound. The last increase in the contract price was in August.

According to theScanPlast review, in the first ten months of 2022, the estimated consumption of polyethylene (excluding exports to Belarus and Kazakhstan) amounted to 2,116.68 thousand tons, which is 7% more than in the same period a year earlier. The supply of LDPE and LDL has increased.

Major U.S. polyethylene producers include Chevron Phillips Chemical (CP Chem), Dow, LyondellBasell, ExxonMobil, Formosa, INEOS, Total Petrochemicals, and Westlake.

-A Circular Future with Plastics 2023 will take place in Lyon

EuPC, is delighted to finally announce that the 2023 edition of the Annual Conference A Circular Future with Plastics will be organised together with the French Association Polyvia and Plastics Europe. Hydrogen – PVC – rPET – Recycling

The two-days event will take place on 23rd & 24th May 2023 in Lyon, France. All the conferences, meetings and debates of the Annual Event will take place at the convention space L’Espace Tête d’Or. The three associations will bring together over 250 plastic converters active in different markets in the plastics value chain from across Europe, for debates and networking opportunities.

The first day is dedicated to three market division meetings, focusing on packaging, building & construction and automotive & transport. During these meetings, experts from the three sectors present and discuss the most important recent developments.

The long-awaited Main Conference and Debate of the second day will be once more moderated by the journalist Mrs. Melinda Crane. Representatives of national and European politics, CEOs of the plastics manufacturing and converting world, as well as other industry leaders will share their knowledge and experience about the trends of the sector.

In the light of the most recent developments on the European level, and based on the ever-growing importance of themes like climate change, circularity and sustainability, re-use, recycling & waste prevention, the recurring title for the event and debates “A Circular Future with Plastics” could not have been better chosen.

Companies supporting the event will be announced in January 2023. Tickets will be available for sale beginning of next year.

-Solo expands Re:cycled collection with luggage line

Solo, the leading New York based travel and day bag brand, announces today the debut of its first-ever luggage collection. The new luggage line is an expansion of the brand’s existing Re:cycled Collection,

Solo’s Re:cycled Collection bags , first introduced in 2020, are made from plastic removed from landfills near oceans and waterways, giving new life to discarded plastic bottles.

The discarded plastic bottles are re-spun into high quality and lightweight recycled PET Polyester yarn, which is then used for in the various products produced by Solo, including backpacks, roller bags, laptop sleeves, totes, and duffels.

The new luggage collection features six new bags: soft-sided and hard-sided carry-ons as well as checked bags, in both two-wheel and spinner models, featuring materials from recycled PET, ocean-bound plastic water bottles and recycled ABS plastic made from household appliances and automobile parts. Hydrogen – PVC – rPET – Recycling

“We are proud to premiere one of the most sustainable luggage collections on the market at a time when green travel choices are more important than ever,” said Solo CEO Richard Krulik.

Sustainability is an essential pillar of the brand, which has emerged as a leader in the industry for its commitment to bettering the environment. Solo is on a mission to eliminate 40 million plastic water bottles from landfills by 2024. ‘Together with the brand’s “Leave No Trace” packaging, travelers can be assured that they are making an eco-friendly purchase that treads lightly on the Earth,’ the company said.

-Increased recycling potential at waste management facilities thanks to AI

Keymakr, a data annotation service provider, partners with Recycleye, a developer of digital tools for detecting and providing analytics on waste management, to help reduce the amount of recyclable materials that go into landfills.

Despite the growing prevalence of recycling facilities and infrastructure in many parts of the world, an estimated 91 percent of plastics end up in landfills. Waste-management sorting facilities aim to reduce the amount of waste getting buried in landfills by separating anything that can be reused, including for industrial and agricultural purposes. With the goal of promoting a healthier environment and being thrifty, sorting waste comes with many inherent risks. Dividing waste from reusable materials is a grueling and dangerous task that leaves workers vulnerable to harmful substances and contaminants, workplace injuries, and other dangers. Hydrogen – PVC – rPET – Recycling

Recycleye leverages Keymakr’s advanced computer vision AI to assist in running its ML models. Recycleye sends Keymakr relevant data to be labeled prior to it being returned and then integrated into the ML models. Part of this process involves Keymakr helping identify edge cases that occur during the sorting process, allowing the ML models to better recognize objects that otherwise would have been sorted incorrectly. Through this collaboration, waste management sorting facilities are able to recycle more materials.

The partnership with Recycleye comes on the heels of Keymakr’s partnership with SeeChange and the launch of Keylabs, its purpose-built SaaS platform. Keylabs enables all companies, regardless of whether they have data annotation teams, to leverage Keymakr’s uniquely effective annotation capabilities. Keylabs’ easy-to-use interface improves the speed of annotation and data sets while ensuring accuracy through its QA abilities.

-HDPE and PP recycling line for Turkish plastics recycler

The recycling line, installed at the company’s recycling facility in Başiskele, Kocaeli Province, began operations in mid-September 2022.

Featuring Starlinger’s special high-vacuum degassing unit, the recoSTAR dynamic 215 C-VAC has a production capacity of two tons of high-quality plastic pellets per hour and processes post-consumer HDPE and PP bottle flakes. The line is equipped with a SMART feeder, which ensures ideal material preparation prior to extrusion, effectively drying and homogenising the input material. Hydrogen – PVC – rPET – Recycling

“The Starlinger recoSTAR dynamic recycling lines have been designed with the focus on processing contaminated and highly humid post-consumer plastic waste,” explained Paul Niedl, Commercial Head of Starlinger recycling technology. “The elaborate construction of the SMART feeder allows the recycling of materials with higher levels of humidity. In combination with Starlinger’s Dynamic Automation Package, which regulates the ideal operating point, it achieves a significant output increase.”

The specially developed C-VAC degassing unit with its modern cascade setup takes care of volatile contaminants after the main extruder, effectively removing them by expanding the melt surface by 300 percent

Tanrıkulu supplies the produced regranulate to the Turkish plastic product manufacturing industry. While recycled polypropylene is used mainly to produce automobile plastic parts, furniture, toys, and other injection-molded products, as well as pallets, buckets, and packaging films, recycled polyethylene is used for pipes, bottles, plastic bags, and similar products.

“At Tanrıkulu, we try to improve ourselves at every opportunity we get. For that, we continuously upgrade our production equipment”, said İzzet Tanrıkulu, General Manager of Tanrıkulu Group of Companies. “To ensure the best regranulate quality, the post-consumer input material passes through metal detectors and filtration systems before being washed and sorted. The excellent vacuum degassing capacity of the Starlinger line combined with its high production output helps us achieve the best product quality at favourable costs, ensuring continuous supply of high-quality PP and PE regranulate to our customers.”

With currently ten plastics recycling and manufacturing plants in various parts of Kocaeli Province, which borders the Istanbul metropolitan area, Tanrıkulu originally started out in 1989 in Istanbul, recycling paper, glass, and metal waste. In 2006, the company began to produce regranulate from plastic waste and diversified by adding a facility for the production of PET sheet in 2014. Since then, Tanrıkulu has become one of the leading plastic recycling enterprises in Turkey and exports 50 % of its PET sheet products to overseas markets. Its plastic recycling capacity doubled after opening the Izpack PET packaging production facility in 2018 and installing automatic plastic sorting systems in 2019. Hydrogen – PVC – rPET – Recycling

Hydrogen – PVC – rPET – Recycling