InfraredFibres Petrochemicals Hydrogen 25-06-2021 - Arhive

InfraredFibres Petrochemicals Hydrogen

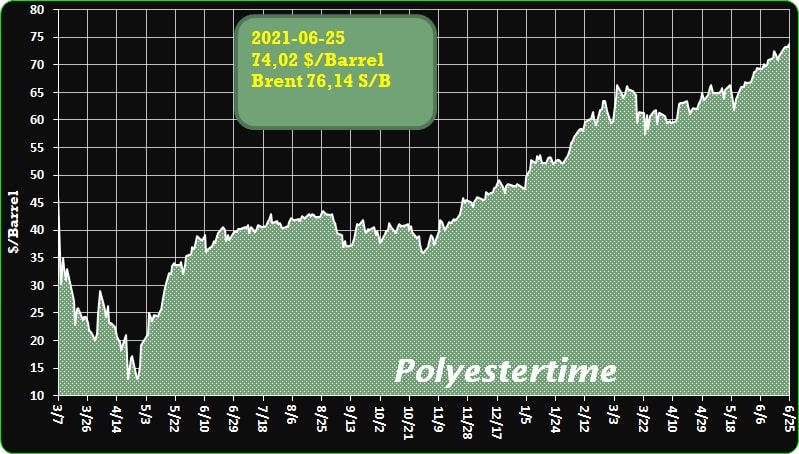

Crude Oil Prices Trend

Indorama Ventures Xylenes & PTA, LLC (IVXP), a subsidiary of global chemical producer Indorama Ventures Public Company Limited (IVL), announces new PNDA (Purified 2,6-Naphthalene Dicarboxylic Acid) production unit, making IVXP the world’s largest PNDA producer. The unit is located at IVXP’s integrated manufacturing site in Decatur, Alabama, U.S.

The company used in-house technology to design and develop the new unit, which was built with equipment mostly made in the U.S. IVXP’s PNDA maintains the highest 99.8% purity level, with extremely low levels of metals and other organics. The unit can produce enough PNDA to fulfil current and forecast global demand for the next 10 years.

IVL is the only large-scale commercial producer of NDC (Dimethyl 2,6-Naphthalene Dicarboxylate) monomers. In addition to PNDA and NDC production, it offers a wide range of naphthalate polymers such as PEN (Polyethylene Naphthalate), PEN-Copolymers, PBN (Polybutylene Naphthalate), and other specialty naphthalates.

-Rewind Mix process pushes pyrolysis agenda

Repsol, Axens and the French research and training centre Ifpen, have joined forces to develop a pioneering process to enhance the chemical recycling of plastics waste and boost circular materials production.

The Rewind Mix process removes impurities such as silicon, chlorine, diolefins, and metals from the plastics pyrolysis oils produced, allowing the direct and undiluted feed to petrochemical units. InfraredFibres Petrochemicals Hydrogen

Pyrolysis is one of the most promising pathways for the chemical recycling of plastics waste, which otherwise would end up incinerated or in landfills, and the production of food-grade, low-carbon footprint, recycled plastics. This new pyrolysis oil upgrading process will expand its deployment and allow the massive introduction of recycled pyrolysis oil in existing steam cracking assets.

Polyolefins from petrochemistry represent about half of the 400 million tonnes a year of world plastics production and a major target in terms of plastic recycling. Today, mechanical recycling faces limitations due to feedstock quality (mix of polymers and impurities content) that directly impact product quality and potential applications, in particular for food-grade use.

The Rewind Mix process has been developed at the Repsol Technology Lab and Ifpen facilities, with extensive pilot plant testing of representative pyrolysis oils, reproducing the exact conditions of the future industrial plant. It can be integrated within existing petrochemical units.

-BRIGHT GREEN PLASTICS INVESTS SEVEN-FIGURE SUM INTO NEW RECYCLING FACILITIES

Bright Green Plastics has invested a seven-figure sum into upgrading its facility with new innovative washing and extruding machinery, allowing for the increased recovery of post-consumer plastic waste. InfraredFibres Petrochemicals Hydrogen

The Yorkshire-based recycling firm recovers and repurposes discarded plastic, processing more than 40,000 tonnes of the UK’s plastic waste every year.

Recycled polymerThe firm’s new wash plant is designed to shred, wash, purify and granulate post-consumer waste into ready-to-recycle flake product.

Processing up-to five tonnes per hour, the machine recycles all its own water and will produce the firm’s purest ever polypropylene (PP) and polyethylene (PE) flake.

The upgraded extruder is designed to melt the disused plastic and transform it into recycled pellets, ready to be put back into the manufacturing cycle. It will process up to three tonnes of PP and PE plastic per hour, and allow the firm to work with material previously too difficult to handle, such as flexible plastics.

-Processing plastic flakes directly

With a new process, ENGEL makes it possible to process plastic waste as flakes in injection moulding directly after grinding. Since a complete process step, pelletising, is eliminated, the innovation significantly improves cost efficiency in plastics recycling.

At its live e-symposium 2021 from 22 to 24 June, ENGEL is presenting the new two-stage process to a trade audience for the first time and demonstrating its great potential. The new process also offers benefits in the production of very large and thick-walled components with high shot weights. InfraredFibres Petrochemicals Hydrogen

The key to shortening the recycling process is breaking down plasticising and injection into two independent process steps that are very well tuned with each other. In the first stage, the raw material, for example plastic flakes originating from post-consumer collection, is melted in a conventional plasticising screw. In the second stage of the process the melt is transferred to a second screw for injection into the cavity. The two-stage process makes it possible to integrate a melt filter and a degassing unit on the injection unit side of the injection moulding machine, so that products with a consistently high quality are obtained even from contaminated plastic flakes.

This innovation sees ENGEL make a further contribution to the establishment of a circular economy for plastics. Pelletising the recycled material is an energy-intensive process which typically also involves logistics overhead. If this step can be eliminated, the CO2 footprint is improved and recycling costs are also significantly reduced.

-Research Continues into Cost-Effective Production of PHA

A technology developed by Yield10 Bioscience that produces camelina seed containing high levels of PHA bioplastic marks a “significant step toward commercial production of PHA in plants,” said the compan InfraredFibres Petrochemicals Hydrogen

Yield10 Bioscience, an agriculture bioscience company based in Woburn, MA, recently featured a presentation by Chief Science Officer Dr. Kristi Snell at the 2021 Synthetic Biology Engineering, Evolution & Design (SEED) conference on June 18. Snell described how Yield10 researchers programmed prototype plants with microbial genes based on a patent filed for new technology that produces camelina seed containing high levels of PHA bioplastic suitable for field production.

Yield10 Bioscience (formerly Metabolix) has a long history of developing PHA. Metabolix was founded in 1992, and a partnership with Archer-Daniels-Midland (ADM) held high hopes for success, when Metabolix promised 50,000 tons per year of PHA from its Iowa-based bioplastics facility in 2007. That collaboration fell through, and Metabolix changed its name to Yield10 and began work on developing PHA using camelina seed.

Proof-of-concept for field production of PHA in Camelina sativa.

In 2020, several camelina lines were grown in small plots at field test sites in the United States and Canada. Compared with control plants, the engineering PHA camelina lines emerged and matured later, but once established, they exhibited good vigor, branching, flowering, and seed set, explained Yield10. Levels of PHA produced in seed measured up to 6% PHA of mature seed weight depending on the plant line tested, demonstrating proof-of-concept for field production of PHA in Camelina sativa using the new technology.

-Infrared fibres for pure white fabrics

Pacific Palisades – The Hologenix R&D team has found a way to embed its flagship product, Celliant, into fibres that allow for fabrics and nonwovens based on them to be pure white. InfraredFibres Petrochemicals Hydrogen

This expands the potential applications of Celliant to crisp white bed sheets and towels, athletic uniforms and jerseys, baby clothes, medical scrubs and more, while maintaining the product’s well-known wellness benefits. Pure white possible Celliant also allows delicate pastel shades to be achieved

Pure white Celliant still captures and converts body heat into infrared energy, increasing local circulation, helping regulate body temperature and promote stronger performance, faster recovery, and better sleep. It is also still made from ethically sourced minerals from the earth and is available in nylon, polyester and recycled polyester fibres.

“We are constantly looking for ways to improve and bring new possibilities to Celliant’s infrared wellness benefits,” said Seth Casden, co-founder and CEO of Hologenix, headquartered in Pacific Palisades, California. “Pure white Celliant delivers, and we are very satisfied.

-Trinseo and BASF to expand their business with SM production based on circular feedstock

Trinseo, a global materials company and manufacturer of plastics, latex binders, and synthetic rubber, and BASF, the world’s petrochemical major, have announced the intention to expand their businesses with the production of styrene monomer (SM) based on circular feedstock, according to GV.

Trinseo has procured first supplies of SM based on circular feedstock from BASF for use in its Solution-Styrene Butadiene Rubber (S-SBR) and polystyrene (PS) products. Trinseo supplies S-SBR to major tyre manufacturers while its PS products are used in applications such as food packaging and appliances. The first few customers have already processed the material, said the company. InfraredFibres Petrochemicals Hydrogen

“By creating synergy across the value chain, the Trinseo-BASF collaboration is an important move towards helping our customers reach their sustainability goals as well as the development of a truly circular economy,” said Nicolas Joly, Vice President, Plastics & Feedstocks of Trinseo. “The initiative is also in line with Trinseo’s 2030 Sustainability Goals announced earlier this year.”

“CO2 emission reduction and a circular economy are BASF’s paramount targets. Using circular feedstocks instead of virgin fossil resources contributes directly or indirectly to an improved CO2 footprint of subsequent products,” said Klaus Ries, Vice President for BASF’s Styrenics Business Europe. “While our customer Trinseo procures biomass balanced (BMB) styrene for their downstream business already, styrene Ccycled will be available in the near future”.

A complete research offering of comprehensive analysis of the market share, size, recent developments, and trends can be availed in this latest report by Big Market Research. InfraredFibres Petrochemicals Hydrogen

As per the report, the Global Polybutylene Terephthalate (PBT) Market is anticipated to witness significant growth during the forecast period from 2020 to 2025.

The report provides brief summary and detailed insights of the market by collecting data from the industry experts and several prevalent in the market. Besides this, the report offers a detailed analysis of geographical areas and describes the competitive scenario to assist investor, prominent players, and new entrants to obtain a major share of the global Polybutylene Terephthalate (PBT) market.

Our analysis involves the study of the market taking into consideration the impact of the COVID-19 pandemic. Please get in touch with us to get your hands on an exhaustive coverage of the impact of the current situation on the market.

The report presents a summary of each market segment such as type, end-user, applications, and region. With the help of pie charts, graphs, comparison tables, and progress charts a complete overview of the market share, size, and revenue, and growth patterns areaccessible in the report.

Export freight skyrocketed recently, which has become a new norm. Some freight charges to the Americas and Europe have already exceeded $10,000 per 20-foot container. So what is happening in the European and American markets on the other side of the ocean? InfraredFibres Petrochemicals Hydrogen

Firstly, contract price of PET bottle chip in North America has risen to more than $2000/mt, and the spot price is even higher. DAK’s bottle chip plants in Brazil and Argentina still have some problems, and will now and then shut down for short term, hence operating rate is not stable. Local market supply will remain tight for some time. In addition, neighboring countries have also changed the trade pattern that used to be dominated by domestic markets or imports. For example, affected by the epidemic this year, Brazil imported only a few thousand tons of PET in the past few months, while its exports reached tens of thousands of tons, basically going to the major local markets in South America.

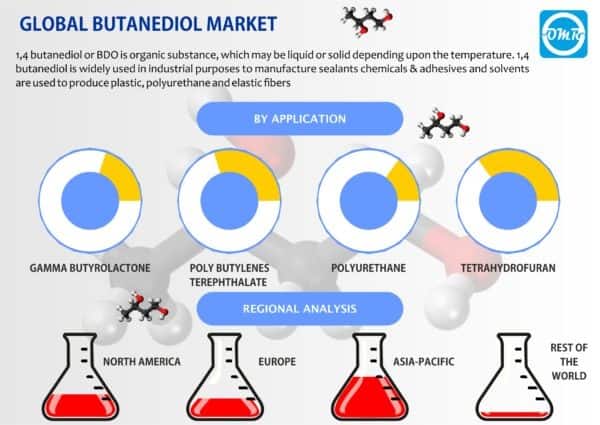

-BDO: coming turnaround season drives price to touch bottom

Price of BDO curved a deep “∧-shape” tendency in the first half of 2021: BDO price surged after the Lunar Chinese New Year holiday with strong demand, supply crunch outside China due to unit issue and speculative mindset on the market, soared by 143% by early-Mar, touching periodical peak, but kept falling thereafter, especially rapidly in Apr with decrement at around 47%, which was close to the level at the beginning of 2021. InfraredFibres Petrochemicals Hydrogen

Supply is expected to decrease: after price plunged, the news that some large BDO plants are scheduled to have turnaround in Q3 inject confidence into the market. Blue Ridge Tunhe, Xinjiang Xinye, Xinjiang Markor, Sinopec Great Wall all intend to have yearly maintenance in Q3, which will cover 0.56 million tons/year of capacity and account for near 26% of total capacity nationally.

Demand grows: demand improved stably. Operating rate of PBT plants has increased to near 70% now, up by around 40 percentage points compared with Apr, and PTMEG plants almost ran at full capacity. That meant support from the major 2 sectors strengthened. In addition, demand from TPU and GBL market also grew.

InfraredFibres Petroche