LNG-Qatar – Films – Green-hydrogen 08-09-2022 - Arhive

LNG-Qatar – Films – Green-hydrogen

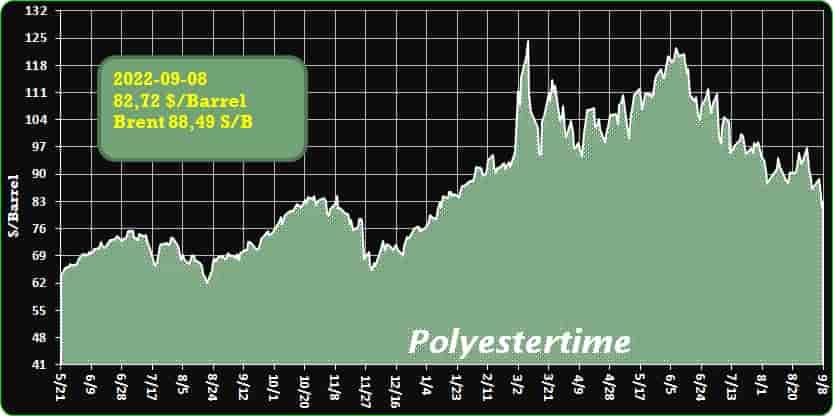

Crude Oil Prices Trend

-Eni enters world largest LNG project in Qatar

QatarEnergy has selected Eni as a new international partner in the North Field East (NFE) expansion project, said the company.

The Minister of State for Energy Affairs, President and CEO of QatarEnergy, Saad Sherida Al-Kaabi, and Eni CEO, Claudio Descalzi signed a partnership agreement for a new joint venture company during the official ceremony on Sunday.

QatarEnergy will hold a 75% interest while Eni will hold the remaining 25% interest, the company said.

The joint venture will hold a 12.5% interest in the entire NFE project, including four mega LNG trains with a combined capacity of 32 million tons per annum (MTPA).

The NFE project will expand Qatar’s LNG export capacity from the current 77 MTPA to 110 MTPA. ‘A $28.75 billion investment, NFE is expected to start production before the end of 2025 and will deploy state-of-the-art technologies to minimize overall carbon footprint, including carbon capture and sequestration,’ Eni announced.

The agreement marks the completion of a competitive process that started in 2019 and which will run for 27 years. LNG-Qatar – Films – Green-hydrogen

The deal is seen as a strategic move for Eni, expanding its presence in the Middle East while gaining access to a world-leading LNG producer and detaining some of the largest natural gas reserves in the world.

We remind, Eni informs that it has acquired the company Export LNG Ltd, which owns the Tango FLNG floating liquefaction facility, from Exmar group. The facility will be used by Eni in the Republic of Congo, as part of the activities of the natural gas development project in the Marine XII block, in line with Eni’s strategy to leverage gas equity resources. The Tango FLNG, built in 2017, has a treatment capacity of approximately 3 million standard cubic meters/day and an LNG production capacity of approximately 0.6 million tons per year (about 1 billion standard cubic meters/year).

-Trioworld to acquire Quality Films

Trioworld Group has signed an agreement to acquire the British company Quality Films LTD (Quality Films), a strong player in solutions for high-performance stretch film for load security. Quality Films supports customers in the areas of distribution, beverage, food, and other industrial packaging. Seller is a group of private owners consisting of Matthew Nicholson with family and Sonia Griffiths.

Trioworld is very pleased to welcome Quality Films into the Trioworld group. Quality Films is a very strong player in the UK market and have shown strong development over the past years, contributing to safer transportation of goods on UK roads. The company is well-invested, and management is focused on strengthening their offering with circular solutions which is in line with Trioworld’s ambition to be the circular leader in the load security market. LNG-Qatar – Films – Green-hydrogen

“With our joint forces, we will continue to develop in the UK market with focus on sustainable high-performance solutions for load security”, says Per Holtstrand, Divisional President of Stretch Film Division, in Trioworld Group.

“We see Trioworld as a very good owner and partner in developing our business to the next level” says Matthew Nicholson, CEO at Quality Films. “Both parties bring strong knowledge of top-quality products, close customer service, and circular solutions to the market. Together we will be able to create more value for our customers,” Matthew Nicholson continues.

CEO for Trioworld Group, Andreas Malmberg comments: “I’m very happy that Quality Films will join our journey in developing the best circular offering in the market for recycled plastics. Quality Films superior commitment to innovative products and customer support in UK gives a fantastic platform for enhanced growth”.

-Maire Tecnimont awarded contract for renewable hydrogen plant in Portugal

Maire Tecnimont S.p.A. announces that its subsidiary NextChem has been awarded a Pre-FEED engineering services contract by MadoquaPower2X to develop and operate an integrated renewable hydrogen and green ammonia plant located in Sines, Portugal, said the company. LNG-Qatar – Films – Green-hydrogen

The agreement was signed at Gastech at the presence of H.E. Joao Galamba, Secretary of State for Environment and Energy – Government of Portugal. The purpose of the Pre-FEED engineering services includes early studies, technology and process review, modularity and logistics analysis, front end loading of engineering required to undertake the permitting and licensing for the project.

MadoquaPower2X will use renewable energy and 500 MW of electrolysis capacity to produce annually 50,000 tons of green hydrogen along with green ammonia plant capacity of up to 500,000 kt/y with up to 600,000 t/y CO2 emissions avoided in this initial phase. It is the first project to be installed at the future energy and technological hub of Sines with an industrial scale. The consortium is committed to developing, installing and operating the project to the highest environmental and safety standards. It will be located in Portugal, in the Sines industrial zone – ZILS – and will generate economic growth with an activity classified as sustainable according to the latest EU Taxonomy. The project is geared towards the set-up of an export energy carrier value chain between the Port of Sines (Portugal) and Northwest European destinations.

-Monoethylene Glycol (MEG) Demand to Surge at 5.4% CAGR Amid Burgeoning Demand for Polyester Fibre

Polyester Fiber and PET Film Application to Collectively Account for Over 50% of MEG Sales

Fact.MR’s latest report on the monoethylene glycol market provides a 10-year forecast through 2022 & beyond. The report further explicates crucial dynamics such as drivers, challenges, and opportunities shaping the market. To present the information in a vivid way, the report has been segmented into application, end user, and region.

The global monoethylene glycol market size is estimated to grow from US$ 38.4 Bn in 2022 to US$ 65 Bn by 2032, with sales surging at 5.4% CAGR throughout the forecast period. LNG-Qatar – Films – Green-hydrogen

Rising usage of monoethylene glycol across diverse industries such as textile, packaging, plastic, and automotive is driving demand in the global market.

Over the years, end uses for monoethylene glycol have significantly widened from clothing and other textiles, through packaging to kitchenware, engine coolants, and antifreeze.

It has become a vital ingredient for the production of polyester fibres and film, engine coolants, antifreeze formulations, and polyethylene terephthalate (PET) resins. Thus, increasing demand for these products will continue to propel the global monoethylene glycol market forward.

Monoethylene glycol is being increasingly used in the manufacturing of coolants for automotive engines. The importance of monoethylene glycol-based liquids for automotive heat transfer in vehicle engines has also caught the interest of industry leaders.

- ARCUS plans to start up first commercial pyrolysis plant for mixed plastic waste in Germany

- Supply of pyrolysis oil from mixed plastic waste enables further expansion of BASF’s ChemCyclingTM business

- Agreement foresees take-up of up to 100,000 tons of pyrolysis oil per year

BASF SE has concluded a framework agreement for the purchase of pyrolysis oil from mixed plastic waste with ARCUS Greencycling Technologies GmbH, a technology company based in Ludwigsburg, Germany. LNG-Qatar – Films – Green-hydrogen

The two companies want to contribute their respective know-how to the value chain in order to return plastic waste that is not recycled mechanically in the sense of a circular economy and reduce CO2 emissions. ARCUS will supply BASF with pyrolysis oil and expand its capacities in the coming years. BASF will use the oil in its production plants as a raw material for the production of Ccycled™ products.

The ARCUS process demonstration unit built in Frankfurt is the first of its kind on a commercial scale in Germany and produces pyrolysis oil from mixed plastic waste that is not recycled mechanically. “With the guaranteed purchase of the oil produced, ARCUS can build further plants with higher capacity and thus make a significant contribution to closing material cycles together with BASF,” said Daniel Odenthal, Chief Operating Officer of ARCUS Greencycling Technologies. The agreement foresees the take-up to be increased to up to 100,000 tons of pyrolysis oil per year.

“The collaboration with ARCUS underscores BASF’s commitment to conserving resources by using recycled raw materials in the chemical industry and to drive the transition to a circular economy,” said Christoph Gahn, Vice President Chemical Recycling Business & Technologies at BASF. “Partnerships with agile, innovative companies are key to achieving these goals. We are pleased to have found such a partner in Germany in ARCUS, who will be able to supply us with commercial quantities of pyrolysis oil for the production of Ccycled™ products in the future. In this way, we support our customers in achieving their sustainability goals.”

The agreement is another building block in the expansion of BASF’s ChemCyclingTM business, which focuses on the chemical recycling of non-recycled post-consumer plastic waste on an industrial scale. BASF will feed the pyrolysis oil supplied by ARCUS into its production network in Ludwigshafen, replacing fossil resources.

The proportion of recycled raw material is allocated to products manufactured in the Verbund using a mass balance approach. The attribution is checked by an independent auditor. LNG-Qatar – Films – Green-hydrogen

-BASF to Collaborate with Sulzer ChemTech

Germany’s BASF and Swiss-based technology firm Sulzer Chemtech have announced plans to collaborate on finding sustainable solutions for a number of industrial applications, in particular renewable fuels and chemically recycled plastics.

The collaboration will blend Sulzer Chemtech’s capabilities in licensed processing technologies and mass transfer equipment with BASF’s strong position in high-performance adsorbents and catalysts. LNG-Qatar – Films – Green-hydrogen

The companies said they will not only seek to drive the development of innovative, cost-effective chemical processing solutions to improve the conversion of plastic waste into new plastics, but also to reduce the carbon intensity of renewable diesel and aviation fuel.

BASF is already engaged in a number of initiatives aimed at converting plastics waste into secondary raw materials, as well as providing adsorbent and catalytic materials to produce clean and renewable fuels.

The German chemical giant recently launched PuriCycle, a line of catalysts and adsorbents solutions that remove or convert a wide range of impurities in pyrolysis oils, a secondary raw material that can be obtained from chemically recycling plastics waste.

Winterthur-based Sulzer Chemtech, an established licensor of process technologies for renewable fuels and chemical recycling of plastics, also collaborates with other chemicals and plastics industry players to harness resources that can help global producers achieve their net-zero ambitions.

Toyobo Co., Ltd. has developed a new biaxially oriented polypropylene (BOPP) film ECOSYARTM VP001, the first transparent vapor-deposition film ECOSYARTM series product that uses a polyolefin*1 material. Sample will be available by end of 2022 and is scheduled to be launched by the end of September 2023. LNG-Qatar – Films – Green-hydrogen

There is an increasing demand for environmentally friendly food and other packaging materials such as products with functions to reduce food loss and with excellent recyclability for reducing the environmental impact of packaging as sustainable awareness continues to rise around the world. Food packing films, which must meet high functionality standards, are made up of several materials with different properties, such as PET films, aluminum foil and polyethylene films. However, these types of packaging, called multi-layer, are not easy to recycle because they contain multiple materials.

ECOSYARTM VP001 is a high gas barrier film for packaging, made by using Toyobo’s vapor deposition technology with a special high-heat resistant BOPP film. This new product has excellent barrier properties against oxygen gas and water vapor, keeping food contents fresh and extending their shelf life to reduce food loss and waste. The product also has excellent heat resistance. Toyobo plans to promote the replacement of films made from other materials with ECOSYARTM VP001 to make polyolefin mono-material packaging for sterilization and general use.

Toyobo has already launched products suitable for mono-material, such as a gas barrier BOPP film DP065 *2 for dry application and OLYESTERTM, a polyester film with a heat-sealing function. Toyobo is committed to helping realize a sustainable society by supplying eco-friendly products. LNG-Qatar – Films – Green-hydrogen

-Unifi New – Consensus Indicates Potential 83.7% Upside

Unifi New found using ticker (UFI) now have 3 analysts covering the stock with the consensus suggesting a rating of ‘Buy’. The target price ranges between 28 and 16 and has a mean target at 20.67. Now with the previous closing price of 11.25 this now indicates there is a potential upside of 83.7%. The 50 day MA is 13.39 and the 200 moving average now moves to 17.25. The company has a market cap of $204mThe potential market cap would be $374m based on the market concensus.

Unifi, together with its subsidiaries, manufactures and sells recycled and synthetic products in the United States, China, Brazil, and internationally.

Its polyester products include partially oriented yarn, textured, solution and package dyed, twisted, beamed, and draw wound yarns in virgin or recycled varieties; and nylon products comprise virgin or recycled textured, solution dyed, and spandex covered yarns. The company also provides recycled solutions made from pre-consumer and post-consumer waste, such as plastic bottle flake made from polyester, and polymer beads and staple fiber made from polyester or nylon. LNG-Qatar – Films – Green-hydrogen

It offers recycled and synthetic products primarily to yarn manufacturers, knitters, and weavers that produce fabric for the apparel, hosiery, home furnishings, automotive, industrial, and other end-use markets.

LNG-Qatar – Films – Green-hydrogen