Meltblown-fabric – POY DTY process 20- 02-2023 - Arhive

Meltblown-fabric – POY DTY process

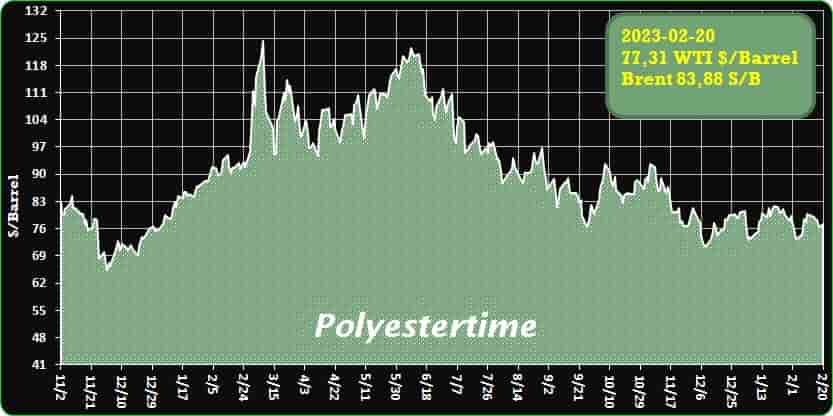

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Petrochemicals – Spandex ADA Ny66

-Suez, Loop Industries, SK Geo Centric select site for new recycled PET facility

Plant will be Europe’s first Infinite Loop production facility

Environmental services company Suez, Quebec-based PET recycler Loop Industries and and SK Geo Centric, a subsidiary of South Korean group SK, have announced that they have now selected a site for the previously announced construction of Europe’s first Infinite Loop plant. The three partners, each of whom has an equal share in the project, have opted to build their planned manufacturing facility at the Chemesis industrial platform in Saint-Avold, located in the Grand Est region of France.

Initially, when the project was announced in 2020, it consisted of just Suez and Loop Industries. Meltblown-fabric – POY DTY process

The partnership was expanded to include SK Global Centric in June 2022, following SKGC’s acquisition of a 10 percent equity stake in Loop Industries the previous year. SK was also given options to acquire additional shares at successively higher prices, and gained representation on Loop’s Board of Directors.

-Roswell launches plant-based meltblown fabric

Nonwovens fabrics manufacturer Roswell Textiles has announced the full commercial launch of Ecofuse, a plant based, low carbon, meltblown material which as well as providing carbon offsets, is designed to replace incumbent synthetic nonwoven materials with more sustainable and environmentally friendly alternative.

Roswell Textiles developed, commercialized, and scaled Canada’s first domestic supply of synthetic meltblown fabric during the COVID-19 pandemic. The company was able to scale production quickly and efficiently, by engineering and manufacturing its own nonwoven production equipment in-house and making its first commercial sale of Canadian produced meltblown material in just two months. Meltblown-fabric – POY DTY process

Building on this process, the company has now launched what it calls the ‘next generation’ of high performance and technical nonwoven materials under the brand name of Ecofuse.

Roswell says it utilizes proprietary production technologies that allow for the technical processing of biopolymers to achieve the high-performance requirements in nonwoven materials that have previously been impossible to achieve at commercial scale. These highly engineered materials are said to possess similar technical specifications as synthetic, polypropylene materials but with a 65% net carbon reduction, contributing to a more sustainable and circular economy, the company says. Meltblown-fabric – POY DTY process

-Oerlikon Barmag WINGS HD with extended parking time for greater efficiency

Since 2018, Oerlikon Barmag has been offering the market’s only currently available concept for high-end home textile applications using the POY and DTY process. The spinning concept with the WINGS HD winding unit in conjunction with an automatic eAFK Big V Multispindle texturing machine manufactures excellent-quality high-titer yarns with maximum machine efficiency.

Superbly suited to the efficient production of high-titer yarns: the Oerlikon Barmag WINGS HD with extended parking time.Meltblown-fabric – POY DTY process

“We have correspondingly modified WINGS HD in order to once again better align the increased requirements of these special yarns to the spinning process and make everyday production even simpler for our customers”, comments Stephan Faulstich, POY Process Technology Manager. The parking times are extremely short when winding high titers. We have increased the parking times by up to three times in the case of the new WINGS HD models. To this end, the parking time for a 300d/384f yarn, for example, has been increased from a standard 6.5 min. to 15.7 min. – and, in the case of a 400d/192f yarn, from 4.3 min. to 10.3 min. This makes the doffing process more even, hence increasing doffing reliability.

-SK geo centric to build S. Korea’s first plastic recycling plant in France

SK geo centric, a chemical business subsidiary of SK Innovation, announced Friday it will build a plastic recycling plant jointly with French partners in Saint-Avold, northeastern France.

The SK subsidiary said it has selected the plant site together with Suez, a French water and waste management company, and Loop Industries, a Canadian plastic recycling technology company. Meltblown-fabric – POY DTY process

“We are happy to achieve a meaningful milestone in selecting a site for our first plastic recycling plant in Europe,” said SK geo centric CEO, Na Kyung-soo.

“We will share the company’s extensive experience in operating petrochemical processes to lead the construction of a sustainable circular economy in Europe.”

The three companies plan to invest about 450 million euros ($478 million) to start the construction of the plant in early 2025. When the plant is completed in 2027, it will have the capacity to supply about 70,000 tons of recycled plastic annually, SK geo centric said.

The three companies signed a business agreement to establish the plastic recycling joint venture in June. Meltblown-fabric – POY DTY process

Located in the center of a densely populated area in northeastern France, Saint-Avold has the best environment to build recycling plants based on efficient industrial infrastructure such as roads and railways, the company said.

-MEGlobal increases March MEG price

MEGlobal has nominated its March 2023 monoethylene glycol (MEG) Asian Contract Price (ACP) at USD860/tonne, up by USD20/tonne from its February ACP, said the company.

The price is on a CFR (cost and freight) Asia basis.

We remind, MEGlobal has nominated its January 2023 monoethylene glycol (MEG) Asian Contract Price (ACP) at USD820/tonne, up by USD20/tonne from the December ACP. The price is on a CFR (cost and freight) Asia basis. Meltblown-fabric – POY DTY process

Asia MEG market has bottomed out in December after China relaxed its COVID curbs, but the upcoming new capacities in China and India may weigh on the prices.

MEGlobal is a fully integrated supplier of monoethylene glycol (MEG) and diethylene glycol (DEG), collectively known as ethylene glycol (EG).

-NextChem and Dimeta to develop plants to make recycled DME from waste

NextChem has signed an agreement with Netherlands-headquartered energy firm Dimeta to develop plants for renewable and recycled carbon dimethyl ether (DME) from waste, said the company.

DME has similar properties to liquefied petroleum gas (LPG), and the recycled material can be blended with conventional LPG to help reduce its carbon footprint without needing to change appliances or infrastructure. Meltblown-fabric – POY DTY process

Dimeta is a Dutch joint venture between SHV Energy and UGI International, which was established to support the production and use of renewable and recycled carbon DME to accelerate the LPG industry’s transition to net zero.

Dimeta aims to produce 300,000 tonnes of DME by the end of 2027 and has established plants in the UK, Europe and US.

The process developed by Maire Tecnimont’s green chemistry venture NextChem and its subsidiary MyRechemical would convert municipal solid waste into methanol and then into DME.

Meltblown-fabric – POY DTY process