Microplastics – Recycled-plastics 27-07-2022 - Arhive

Microplastics – Recycled-plastics

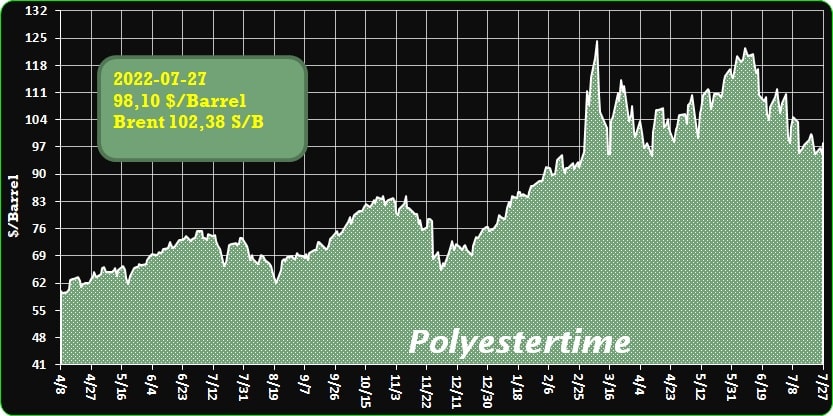

Crude Oil Prices Trend

The war in Ukraine first caused oil price volatility, which increased as surging COVID-19 cases in China led to fresh lockdowns, hitting demand and disrupting supply chains. China is the world’s second biggest economy and largest oil importer.

Now Russia’s decision to reduce flows of natural gas to Europe means the continent has to look forward to a winter of potential rationing, which could hit chemical production. Tightened supply has also sent gas prices soaring, with high costs forcing production cuts, especially in fertilizers.

India is facing a more severe shortage of fertilizers and edible oil amid wide-ranging trade disruptions as the Ukraine war rages on, with financial sanctions tightening on Russia.

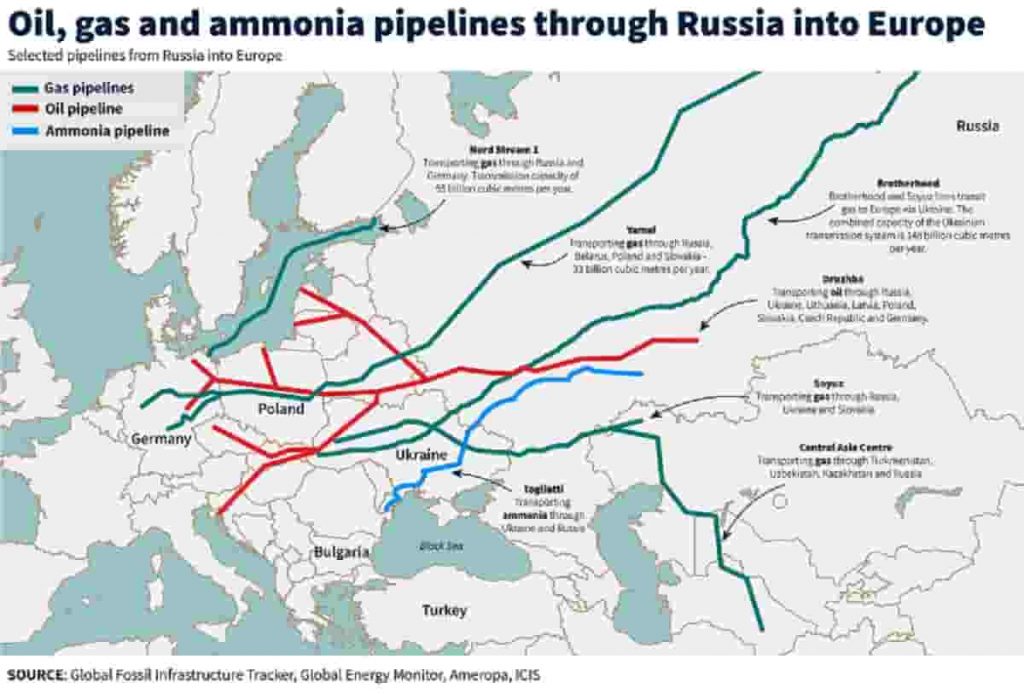

Europe’s energy challenge is immense and put into stark relief by the response to Russia’s war in Ukraine. Cutting the ties that bind EU and non-EU nations to Russian gas and oil will be extremely painful this year and in years to come: the actions proposed by the European Commission put that into context.

This topic page examines the impact of the Ukraine conflict on oil, gas, fertilizer and chemical markets.

Europe’s energy markets witnessed a year of record prices and extreme volatility in 2021. Russia’s invasion of Ukraine has led to more difficult conditions for global markets in 2022.

GAS SUMMARY

Gas storage low in Europe, winter demand 30% higher than rest of year

Record shipments of liquefied natural gas (LNG) to Europe so far in 2022

LNG could ease Europe shortages if Russia supplies cut

Europe LNG processing operating at full capacity

Russia resumed flows through Nord Stream I pipeline, but at reduced levels

EU plan calls for a 15% cut to consumption, industry may face much higher reductions

AMMONIA SUMMARY

Russia supplies 20% of global seaborne ammonia market

Disrupted supply has pushed up fertilizer and food prices

OIL SUMMARY

Friendship oil pipeline flows through Ukraine

Russian oil feeds around a quarter of Europe demand

Europe seeks to end reliance on Russian crude oil

CHEMICALS SUMMARY

High Europe gas and electricity prices force price hikes, energy surcharges

Volatile oil and feedstock prices dent chemical producer margins

Elevated oil prices dent consumer confidence and demand

CEOs plan now for winter gas rationing

BASF says it will have to close Ludwigshafen site if gas supplies fall below 50% for a prolonged period

Europe is heavily reliant on Russian gas and exposed to disruptions in supply, but Russia is also an important oil exporter and a supplier of fossil fuel products, which find their way to international markets via Ukraine’s ports.

Sanctions and measures against Russian exports of oil and gas have sent shockwaves across the global economy, lifting the cost of living, impacting industrial and agricultural production and potentially leading to social unrest.

ICIS has taken a broader perspective, asking how vulnerable energy and energy-related supplies are to disruptions, what contingency plans are put in place and what could be expected in the upcoming weeks.

-Silk offers an alternative to some microplastics

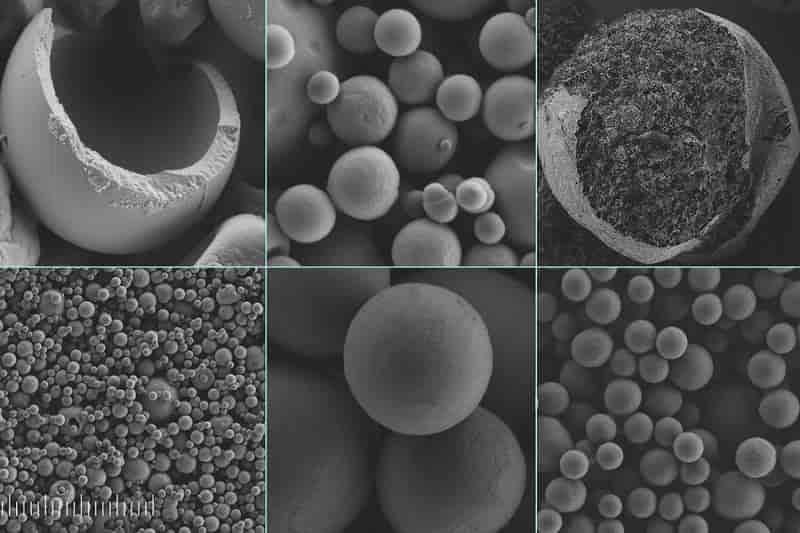

Researchers have developed a biodegradable system based on silk to replace microplastics added to agricultural products, paints, and cosmetics.

Microplastics, tiny particles of plastic that are now found worldwide in the air, water, and soil, are increasingly recognized as a serious pollution threat, and have been found in the bloodstream of animals and people around the world.

Some of these microplastics are intentionally added to a variety of products, including agricultural chemicals, paints, cosmetics, and detergents — amounting to an estimated 50,000 tons a year in the European Union alone, according to the European Chemicals Agency. The EU has already declared that these added, nonbiodegradable microplastics must be eliminated by 2025, so the search is on for suitable replacements, which do not currently exist. Microplastics – Recycled-plastics

Now, a team of scientists at MIT and elsewhere has developed a system based on silk that could provide an inexpensive and easily manufactured substitute. The new process is described in a paper in the journal Small, written by MIT postdoc Muchun Liu, MIT professor of civil and environmental engineering Benedetto Marelli, and five others at the chemical company BASF in Germany and the U.S.

The microplastics widely used in industrial products generally protect some specific active ingredient (or ingredients) from being degraded by exposure to air or moisture, until the time they are needed. They provide a slow release of the active ingredient for a targeted period of time and minimize adverse effects to its surroundings. For example, vitamins are often delivered in the form of microcapsules packed into a pill or capsule, and pesticides and herbicides are similarly enveloped. But the materials used today for such microencapsulation are plastics that persist in the environment for a long time. Until now, there has been no practical, economical substitute available that would biodegrade naturally.

Much of the burden of environmental microplastics comes from other sources, such as the degradation over time of larger plastic objects such as bottles and packaging, and from the wear of car tires. Each of these sources may require its own kind of solutions for reducing its spread, Marelli says. The European Chemical Agency has estimated that the intentionally added microplastics represent approximately 10-15 percent of the total amount in the environment, but this source may be relatively easy to address using this nature-based biodegradable replacement, he says. Microplastics – Recycled-plastics

-Amcor recognised for sustainability efforts

Packaging company Amcor is celebrating being recognised for its sustainability practices by two different bodies.

The Australian Financial Review has listed Amcor as a 2022 Australian Financial Review Sustainability Leader in the Manufacturing and Consumer Goods category, in association with BCG. This list offers recognition to companies that are working to solve sustainability problems. Microplastics – Recycled-plastics

The Australian wing of Amcor was given a nod due to its moves in the last year to convert its products to recycle-ready formats, and for its contributions to a food wrapper composed of recycled content for Nestlé’s KitKat brand.

Additionally, Amcor received recognition at the 2022 Australasian Packaging Innovation and Design Awards (PIDA), taking home the silver award in the Sustainable — Industrial Design of the Year category at PIDA for its PrimeSeal Eco-Tite Recycle-Ready Shrink Bag. Its PrimeSeal Flow-Tite packaging was also named a finalist in two categories: Best Food Packaging Design of the Year and Accessible and Inclusive Packaging Design of the Year.

Simon Roy, Vice President and General Manager for Amcor Australia and New Zealand, said: “It’s terrific to see Amcor’s innovative and more sustainable packaging solutions be recognised by the industry and community in the local market.

“We are a global company with a proud local history that enables us to leverage research and development at scale to produce best-in-class innovations that can be applied either globally or locally, to help meet our customers’ needs.

Intertex signed an offtake agreement to purchase sustainable carbon-negative carbon black from Origin Materials for use in mechanical rubber goods markets, including automotive tires, belts, hoses, and rubber seals Microplastics – Recycled-plastics

-Origin Materials, Inc. (“Origin” or “Origin Materials”) (NASDAQ: ORGN, ORGNW), the world’s leading carbon negative materials company with a mission to enable the world’s transition to sustainable materials, and Intertex World Resources, Inc. (“Intertex”), a leading value-added distributor of synthetic rubber, carbon black, process oils and rubber chemicals, today announced a strategic partnership to bring sustainable carbon-negative carbon black made using Origin Materials’ patented technology platform to the rubber compounding and plastic masterbatch industries.

As part of the partnership, Intertex signed an offtake agreement with Origin Materials to purchase sustainable carbon black. Origin’s carbon-negative carbon black, made from Origin’s HTC, is a versatile 100% bio-content filler and pigment produced from sustainable wood residues rather than petroleum, reducing carbon emissions and fossil resource consumption. Microplastics – Recycled-plastics

The partnership aims to produce carbon black for tires including N660, N550, and N762 specifications, as well as for belts, hoses, rubber seals, plastic extrusion, and all other mechanical rubber goods markets. Origin and Intertex will work to develop a carbon black for automotive seal customers requiring high performance carbon blacks for rubber window seals.

“We are thrilled to partner with Intertex, a strategic sourcing leader with three decades’ experience in product development and distribution,” said Origin Materials Co-CEO Rich Riley. “This collaboration is a significant step forward in our mission to enable the world’s transition to sustainable materials. We expect our sustainable carbon-negative carbon black to be deployed across a diverse array of applications to decarbonize the rubber and automotive supply chain.”

“We are excited to work with Origin Materials on sustainable carbon black and believe it is a great time to partner with this forward-looking company,” said Greg Sibley, Managing Partner for Intertex. Microplastics – Recycled-plastics

-Is Europe ready for a new generation of polymers before it has dealt with legacy polymers?

What is the European Commission planning for polymer innovation? Thus far, have its decisions in this field been misguided? Paul Foulkes-Arellano, founder of Circuthon Consulting, tells us more.

The European packaging industry is facing some big questions:

Is the EU about to extinguish polymer innovation in an attempt to appease environmental campaigners? Microplastics – Recycled-plastics

Has the Commission misunderstood the genuine carbon reductions achievable through recycling as opposed to other means?

Ultimately, do politicians have the slightest idea about packaging, or are they only swayed by the lobbyist sitting in front of them?

These questions have come to my mind, as I have been poring over one clause of the European Commission Circular Economy Action Plan ever since I read it:

In order to ensure that all packaging on the EU market is reusable or recyclable in an economically viable way by 2030, the Commission will review Directive 94/62/EC27 to reinforce the mandatory essential requirements for packaging to be allowed on the EU market and consider other measures, with a focus on: considering reducing the complexity of packaging materials, including the number of materials and polymers used.

It’s in writing – it refers to polymers, but to unspecified “materials” as well. Across the world, whether it be for manufacture, textiles or packaging, there is much promising polymer innovation right now. There is obviously innovation in fossil polymers, and also innovation based on biobased feedstocks (many of these sequesterers of carbon) – encouraged by guidance issued by the very same Commission which is now looking to restrict additional packaging polymers. This is problematic.

And which polymers precisely make the cut? And who decides – the European Commission or the European Packaging Industry? And can the packaging industry speak with one voice? Microplastics – Recycled-plastics

-These startups seek to close the supply-and-demand gap for recycled plastics

Plastics have spiraled exponentially throughout society and the environment to the point that we literally eat and breathe them on a regular basis. More corporations are responding to consumer outrage by using fewer virgin plastics to produce goods and packaging. Microplastics – Recycled-plastics

Using post-consumer plastics instead of raw petrochemicals is one important strategy within a suite of solutions to the global plastics crisis, but waste plastics are expensive, their makeup is hard to decode and the supply has not been reaching companies demanding them.

A 2021 report commissioned by Google projected a global investment of between $426 billion and $544 billion needed to close by 2040 “the plastics circularity gap,” defined as the difference between the volume of plastics produced and the sliver of plastics available from circular supply chains. Boosting the infrastructure to support these circular supply chains is key, the report found.

Among a growing number of circularity startups focusing on plastic, three young companies gaining funding and attention are seeking to build some of this infrastructure and help channel more waste plastics into the manufacture of new goods.

Circular, launched in June and based in Palo Alto, California, is an online marketplace for buyers and sellers of post-consumer recycled plastic. Cirplus has been doing that since 2018 out of Hamburg, Germany. Circularise, founded in 2016 in The Hague, Netherlands, plays a different role, helping buyers and sellers to determine the origins and ingredients of a variety of materials, including recycled and renewable plastics, through its blockchain technology. In May the company announced that it is teaming up with plastic producer Neste. Microplastics – Recycled-plastics

The backdrop

These companies are entering the growing space of firms seeking solutions to strengthen sustainable plastic supply chains and recycling infrastructure. They have an uphill climb against the expectation that plastic production will double by 2050, after it already quadrupled in three decades to 460 million metric tons by 2019.

Only 4.5 percent of plastic was recycled in the United States in 2018, according to the U.S. Environmental Protection Agency. Globally it’s just twice that, according to the Organization for Economic Cooperation and Development, which blamed plastics for more than 3 percent of global greenhouse gas emissions.

Meanwhile, more than 1,000 businesses, government agencies and organizations representing 20 percent of the market for plastics packaging have signed on since 2018 to the Ellen MacArthur Foundation’s (EMF) Global Commitment to galvanize a circular economy for plastics. Microplastics – Recycled-plastics

Among the organizations setting various targets for 2025 — including Apple, Coca-Cola and Walmart — the adoption of recycled plastics, especially PET for packaging, has accelerated the decline in the use of virgin plastic.

-Pyrolysis technology enables ‘closed loop’ solutions in push for circular economy

Krzysztof Wróblewski explores how this thermochemical technique for recovering raw materials from waste can be used to recycle end-of-life tyres

The automotive industry needs transformative change in its technology solutions. It has made progress producing zero-emission electric vehicles by reducing the carbon footprint on the user-end, but the manufacturing process still has a significant environmental impact. Microplastics – Recycled-plastics

From the plant’s electricity consumption to the various materials in the car’s production, the automotive industry has startling statistics.

According to The Guardian, a compact car will produce around 6 tonnes of CO2e during its production lifecycle. And a university publication concluded that the largest share of global greenhouse gas emissions comes from energy consumption (73.2%), where the industrial sector is a major contributor.

Technology is the answer. Pyrolysis can help in closing the loop to make the automotive sector circular, reducing its environmental impact during car production.

Benefits of joining the circular economy

Employing circular methods would allow the automotive industry to reduce vehicle lifecycle carbon emissions by up to 75% and resource use by up to 80% per passenger-km by 2030 for an electric car, according to a World Economic Forum report from Accenture. Closing the loop will also reduce the industry’s ecological footprint by reducing pollution and waste generation and protecting biodiversity. The automotive supply chain will have to change both upstream and downstream to achieve these goals.

“Pyrolysis is a thermochemical technique for recovering raw materials from waste, and can be used to safely recycle end-of-life tyres”

Tyres, which are a source of recurring waste , can be critical to the industry’s circularity. Tyres pollute the environment throughout their lifecycle, from the non-renewable fossil fuels used in manufacturing to the difficulty of recycling waste tyres by conventional methods. Tyre components like synthetic rubber and virgin Carbon Black are derived from petroleum. Carbon Black makes up over 20% of tyre mass; synthetic rubber content can be up to 25% depending on the type, as truck tyres have less.

However, the automotive industry can use existing technologies from other sectors, like pyrolysis, to avoid starting from scratch in its search for circularity. Pyrolysis is a thermochemical technique for recovering raw materials from waste, and can be used to safely recycle end-of-life tyres (ELTs). Raw materials recovered during the pyrolysis process can be used to manufacture new tyres, thus closing the loop for the tyre industry.

Material recovery by pyrolysis

Several types of pyrolysis for ELTs are now available. Essentially, they all heat ELTs at high temperatures, in an oxygen-free atmosphere, to break down the tyres to their raw materials. The pyrolytic products of economic interest are recovered Carbon Black, steel, oil, and gas. Microplastics – Recycled-plastics

Recovered Carbon Black is semi-reinforcing and can partly replace grades like N660. Recovered Carbon Black carbon footprint is several times lower than virgin Carbon Black. The tyre-derived oil (TDO) is a suitable feedstock alternative to fossil fuels for manufacturing reinforcing virgin Carbon Black grades. It can also be used as a chemical feedstock. The recovered steel can be reused in manufacturing tyres too. The recovered gas can fuel industrial plants, making energy processes circular and limiting their carbon footprints.

-Stora Enso and Northvolt partner to develop wood-based batteries

Stora Enso and Northvolt are joining forces to create sustainable batteries using lignin-based hard carbon produced with renewable wood from the Nordic forests. The aim is to develop the world’s first industrialised battery featuring anode sourced entirely from European raw materials, lowering both the carbon footprint and the cost.

The companies have entered into a Joint Development Agreement to create a sustainable battery featuring anode produced from renewable raw materials sourced sustainably and locally in the Nordic countries.

“The joint battery development with Northvolt marks a step on our journey to serve the fast-growing battery market with renewable anode materials made from trees. Our lignin-based hard carbon, Lignode® by Stora Enso, will secure the strategic European supply of anode raw material, serving the sustainable battery needs for applications from mobility to stationary energy storage,” says Johanna Hagelberg, Executive Vice President for Biomaterials at Stora Enso.

Both companies bring key components, competence, and expertise to the battery partnership. Stora Enso will provide its lignin-based anode material Lignode, originating from sustainably managed forests, while Northvolt will drive cell design, production process development and scale-up of the technology.

“With this partnership, we are exploring a new source of sustainable raw material and expanding the European battery value chain, while also developing a less expensive battery chemistry. It is an exciting demonstration of how our pursuit of a sustainable battery industry goes hand-in-hand with creating a positive impact both on society and cost,” says Emma Nehrenheim, Chief Environmental Officer at Northvolt.

Lignin is a plant-derived polymer found in the cell walls of dry-land plants. Trees are composed of 20–30% of lignin, where it acts as a natural and strong binder. It is one of the biggest renewable sources of carbon anywhere.

Microplastics – Recycled-plastics